Cl- corrosion resistant high-strength low-alloy steel bar and production method thereof

A high-strength, low-alloy, steel bar technology, applied in the field of steel bars, can solve the problems of increasing the thickness and compactness of the protective layer, unfavorable and aggravating structural load-bearing, and achieve the effect of good welding performance and mechanical connection performance and economical cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

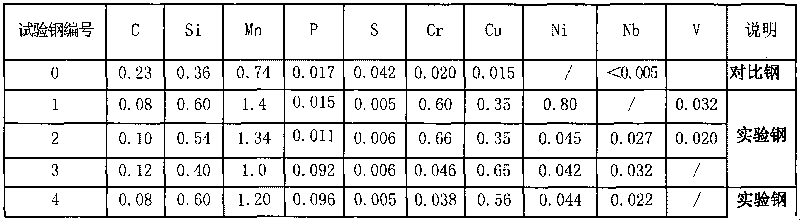

[0017] The ingredients described in Table 1 have undergone steelmaking, continuous casting, and hot rolling. The rolling process adopts the production process of fine-grained steel (starting rolling temperature is 900-950 ° C, controlled rolling temperature is 850 ° C ± 30 ° C, controlled cooling after rolling The temperature is not lower than 600 ℃), rolled into a φ16mm threaded steel bar, and its mechanical properties are shown in Table 2. In order to test the resistance to Cl of steel bar described in the present invention - Corrosion performance, with ordinary carbon steel as a comparison steel, the following experiments were carried out:

[0018] Table 1

[0019]

[0020]

[0021] Table 2: Mechanical properties of test steel

[0022]

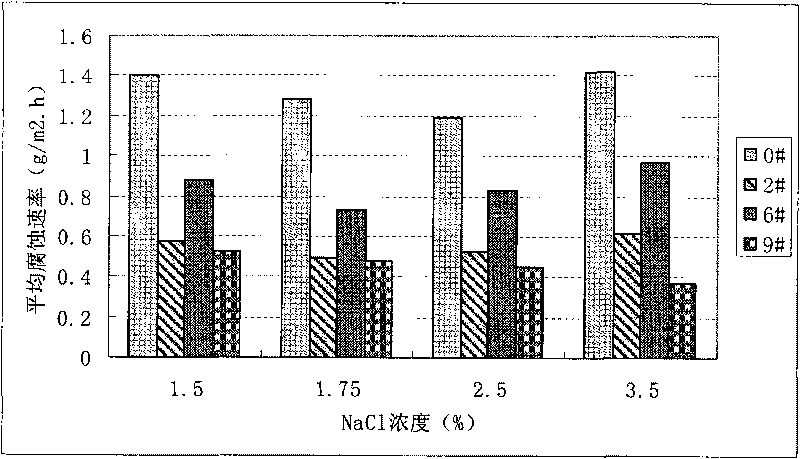

[0023] Refer to TB / T 2375-93 Periodic Infiltration Corrosion Test Method of Weathering Steel for Railways to set the test solution concentration, pH value and accelerated corrosion time. The test conditions are as follows:

[0...

Embodiment 2

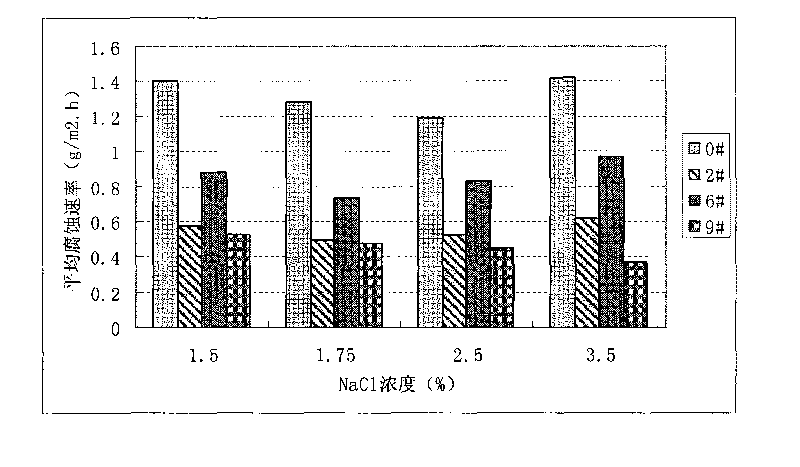

[0037] Using the ingredients described in Table 5, after steelmaking, continuous casting, and hot rolling, the rolling process adopts the production process of fine-grained steel (starting rolling temperature 900-950°C, controlled rolling temperature at 850°C ± 30°C, controlled rolling after rolling The cold temperature is in the range of 600 ° C ~ 750 ° C, rolled into a φ20mm threaded steel bar, its mechanical properties are shown in Table 6. The test method in Example 1 was used to test the Cl resistance of the test steel - Corrosion performance, the average corrosion rate of test steel and comparison steel is shown in Table 7.

[0038] Table 5: Test steel composition

[0039] Test steel number

C

Si

mn

P

S

Cr

Cu

Ni

Nb

illustrate

0 #

0.23

0.36

0.74

0.017

0.042

0.020

0.015

/

<0.005

contrast steel

11 #

0.19

0.64

1.12

0.068

0.008

0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com