Steel structure high altitude mounting method

An installation method and steel structure technology, applied to building components, building structures, roofs, etc., can solve problems such as difficult positioning, difficult to ensure installation accuracy, difficult to ensure accuracy requirements, etc., to achieve the effect of convenient welding and guaranteed manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] First, the general idea of the construction method of the present invention is introduced.

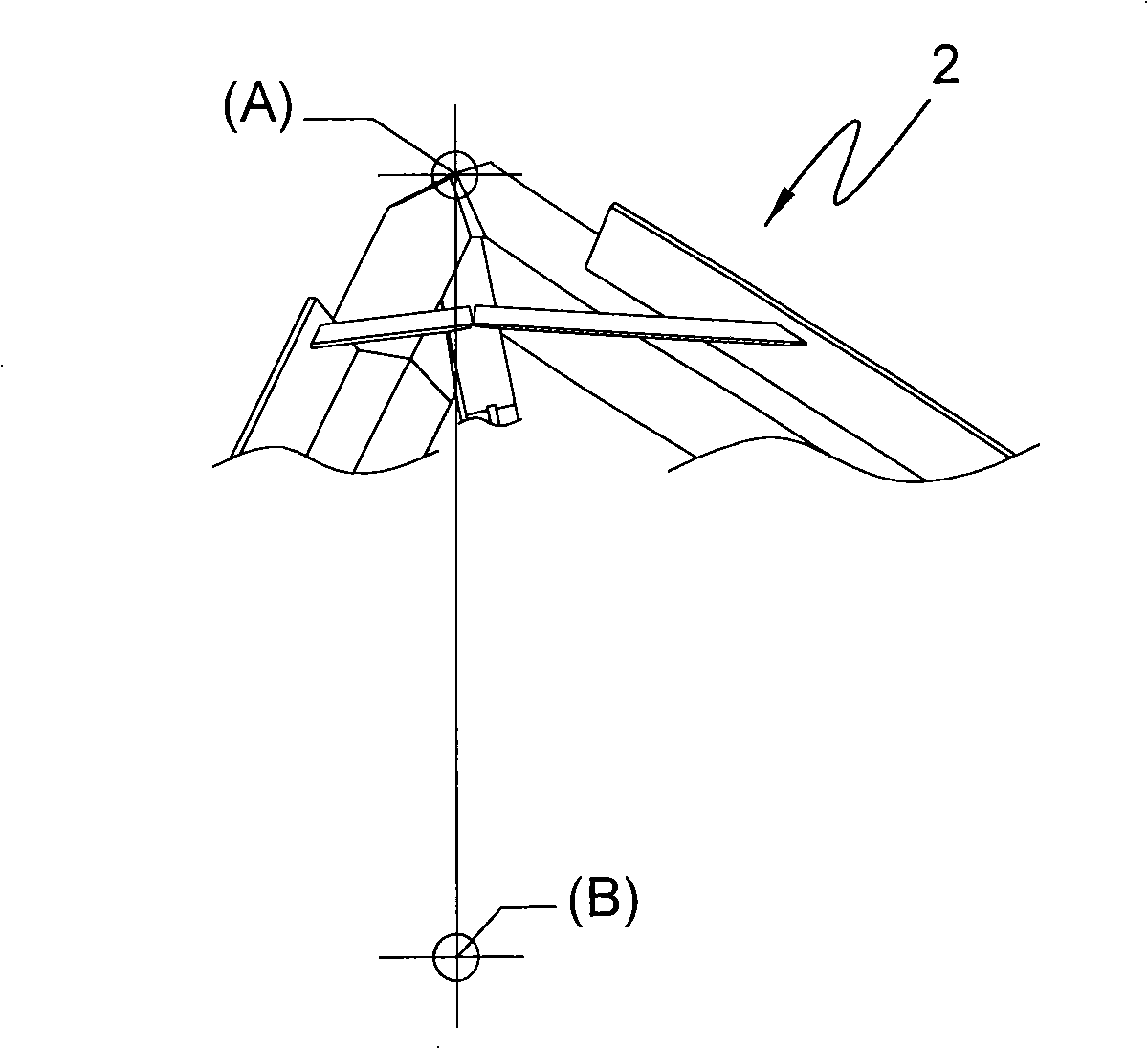

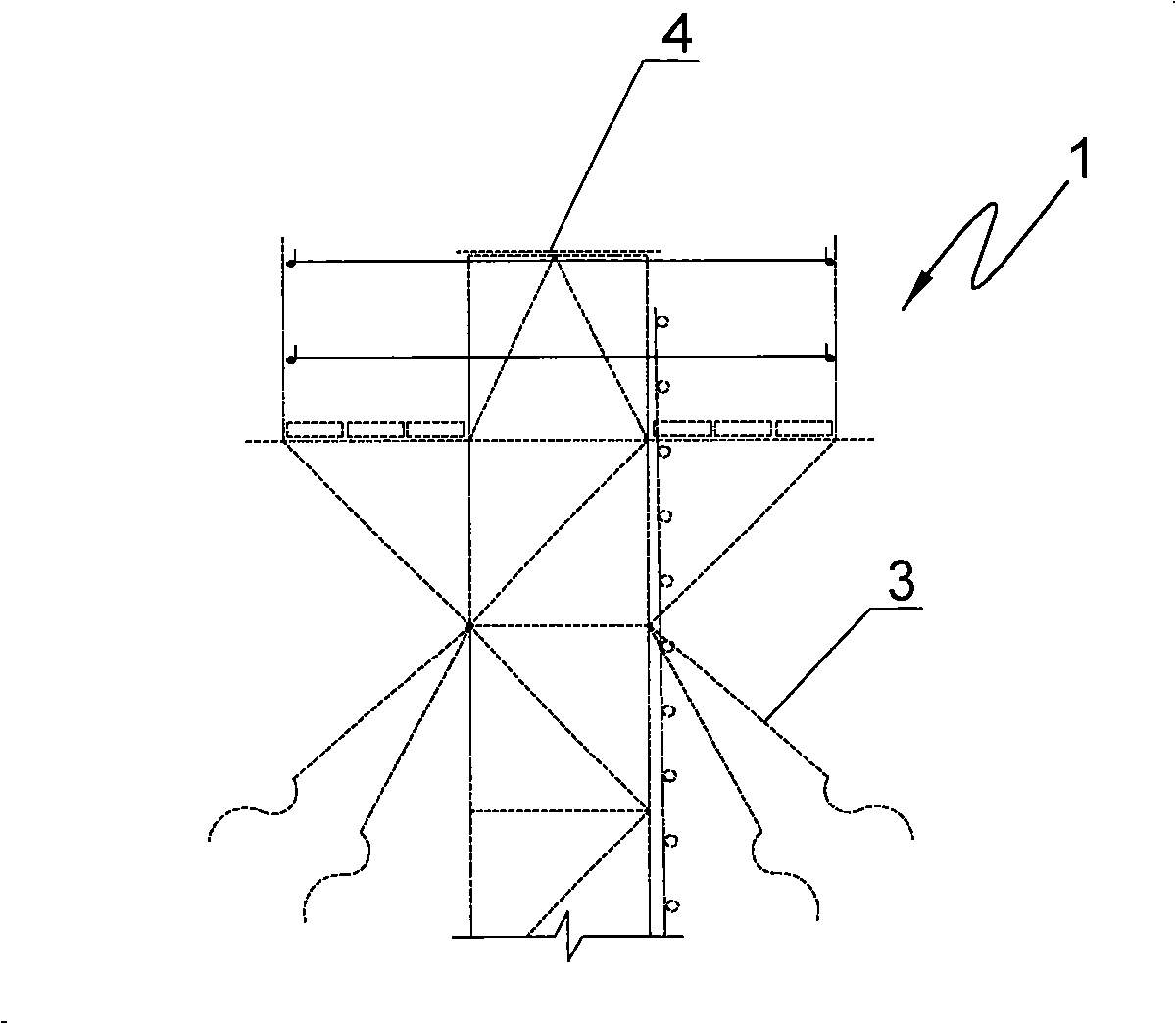

[0047] The main skeleton steel structure is special-shaped square steel pipe or square steel pipe, the wall thickness is mostly 6 and 14mm, and the thickest is 24mm; square steel or rectangular purlins are arranged in parallel and equidistant to the bottom edge of each surface. All structural connections are welded joints.

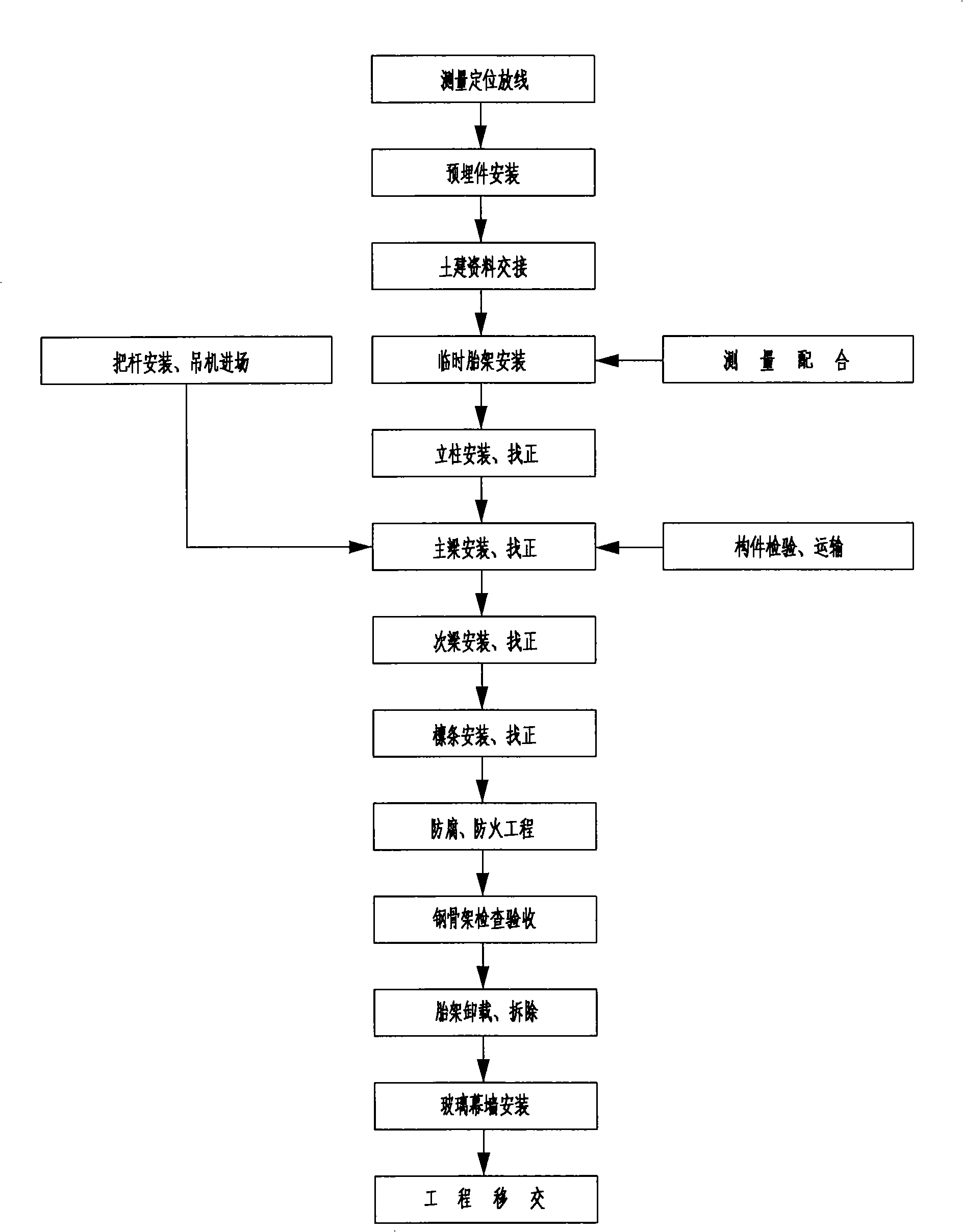

[0048] 1. Construction procedure: according to figure 1 Carry out construction according to the construction procedure shown.

[0049] 2. Countermeasures for engineering difficulties

[0050] 1. Accurate modeling, accurate lofting and cutting, to ensure the accuracy of component manufacturing

[0051] Use AutoCAD to accurately establish the space model of the main frame and purlins, accurately reflect the space angle and size of the component on each surface of the component, correctly draw the production size and cutting angle of each surface of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com