Automatic garment label sewing equipment

A technology for automatic equipment and clothing labels, applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of restricting the productivity of clothing label sewing process, large manual workload, low manual sewing efficiency, etc. Reduce manual labor, save labor costs, and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

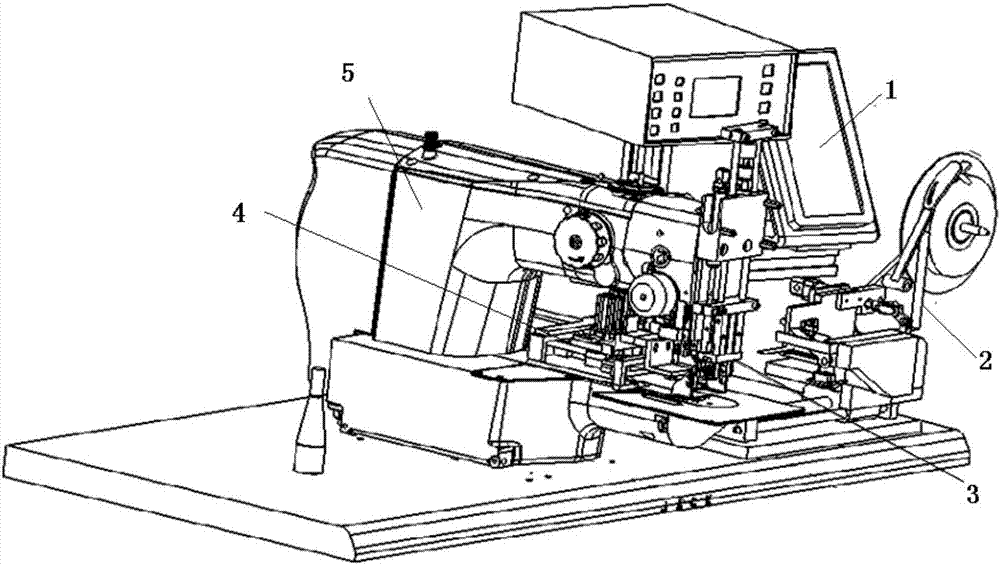

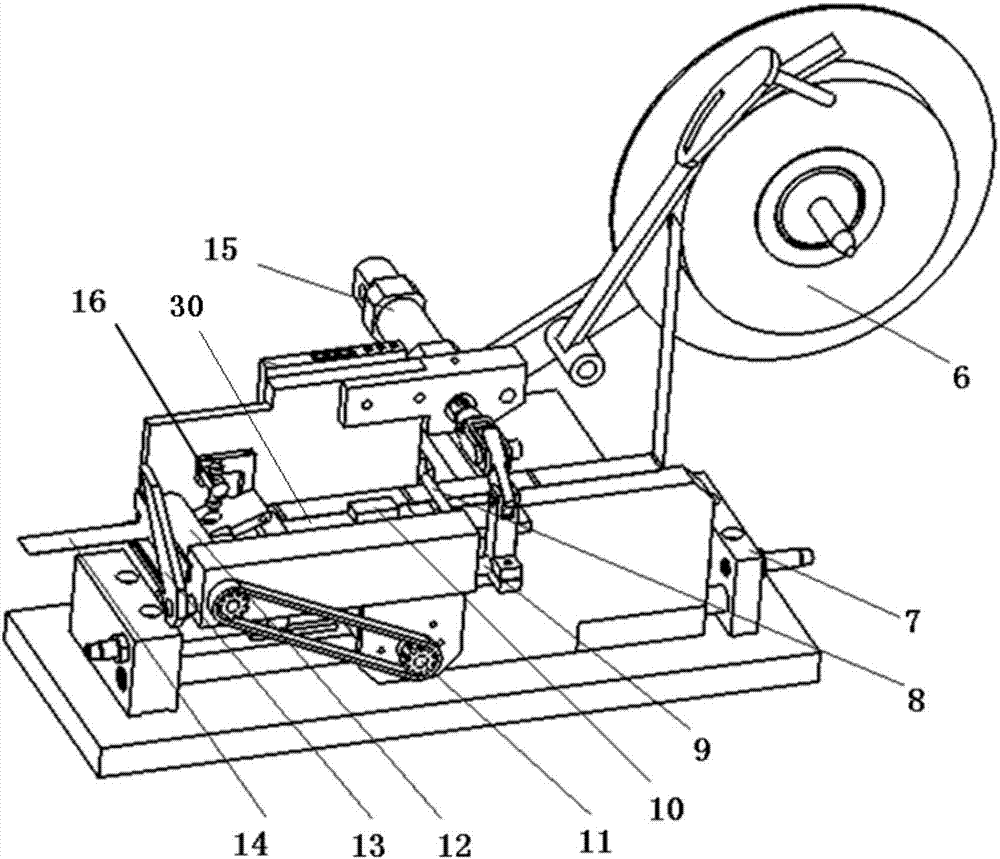

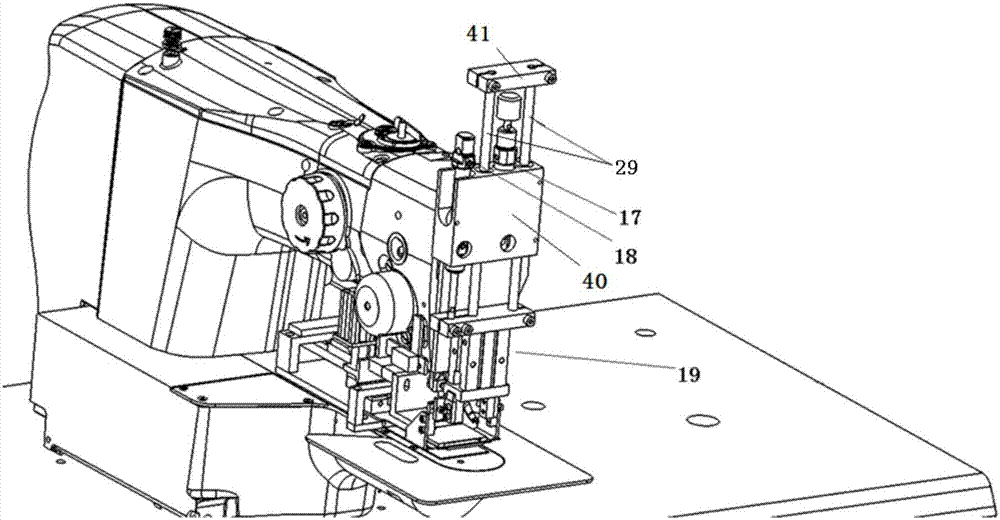

[0023] like figure 1 As shown, an automatic equipment for sewing clothing labels, including a machine platform, on which a tacking machine 5 is arranged, and the tacking machine 5 is used to sew labels onto clothing, and the machine platform at the side of the tacking machine 5 An automatic label conveying device 2 and an operation control mechanism 1 are arranged on the top, an automatic label folding mechanism 3 is installed at the head position of the tacking machine, and an automatic label pressing mechanism 4 is arranged under the head of the tacking machine 5 . The label automatic conveying device 2 automatically conveys the label to the bottom of the label automatic folding mechanism 3 according to the relevant parameters set by the operation control mechanism 1, and the label automatic folding mechanism 3 completes the label folding and folding of the label conveyed to the bottom of the mechanism according to the label sewing process requirements. Precisely place the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com