An aerodynamic optimization method for wind turbine airfoil profile considering a high turbulence free flow effect\

An optimization method and airfoil technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as the unpredictability of the ultimate load of the blade, the increase of fatigue load, and the low aerodynamic efficiency of the blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

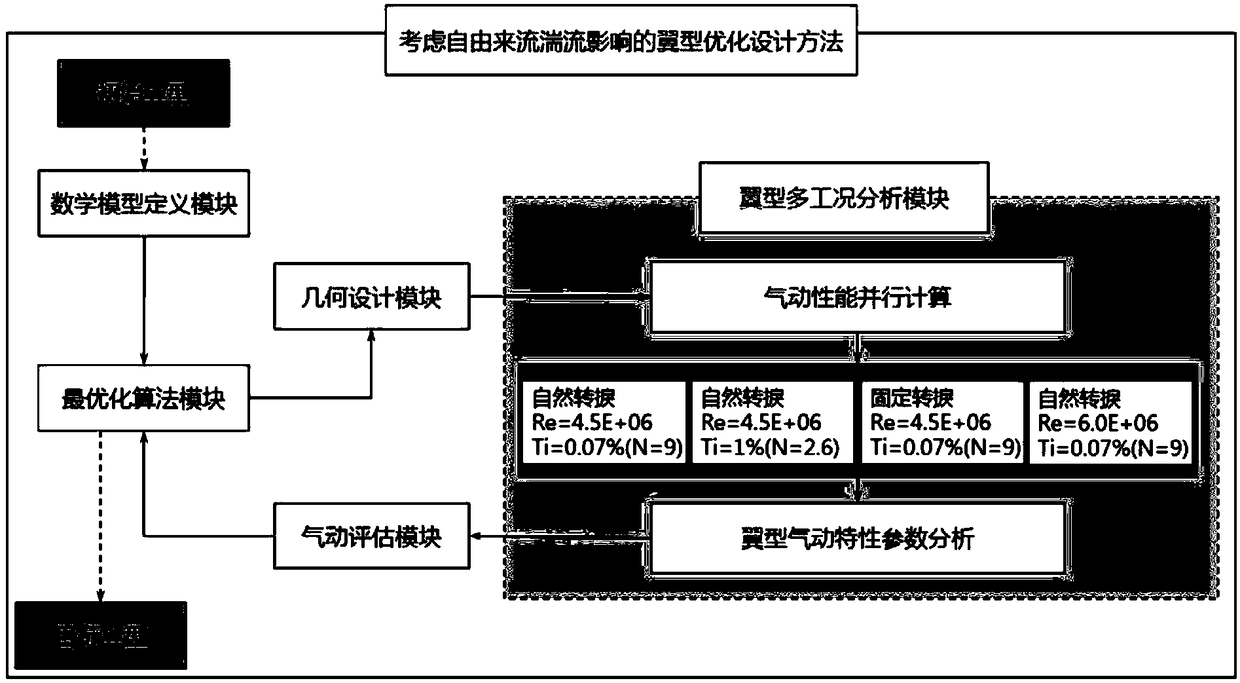

Method used

Image

Examples

Embodiment Construction

[0063] The technical solutions and advantages of the present invention will be described in detail below in conjunction with examples and accompanying drawings.

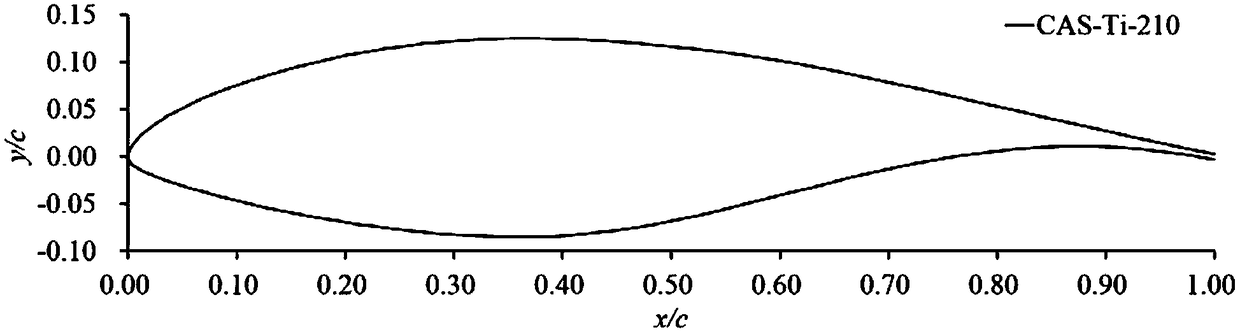

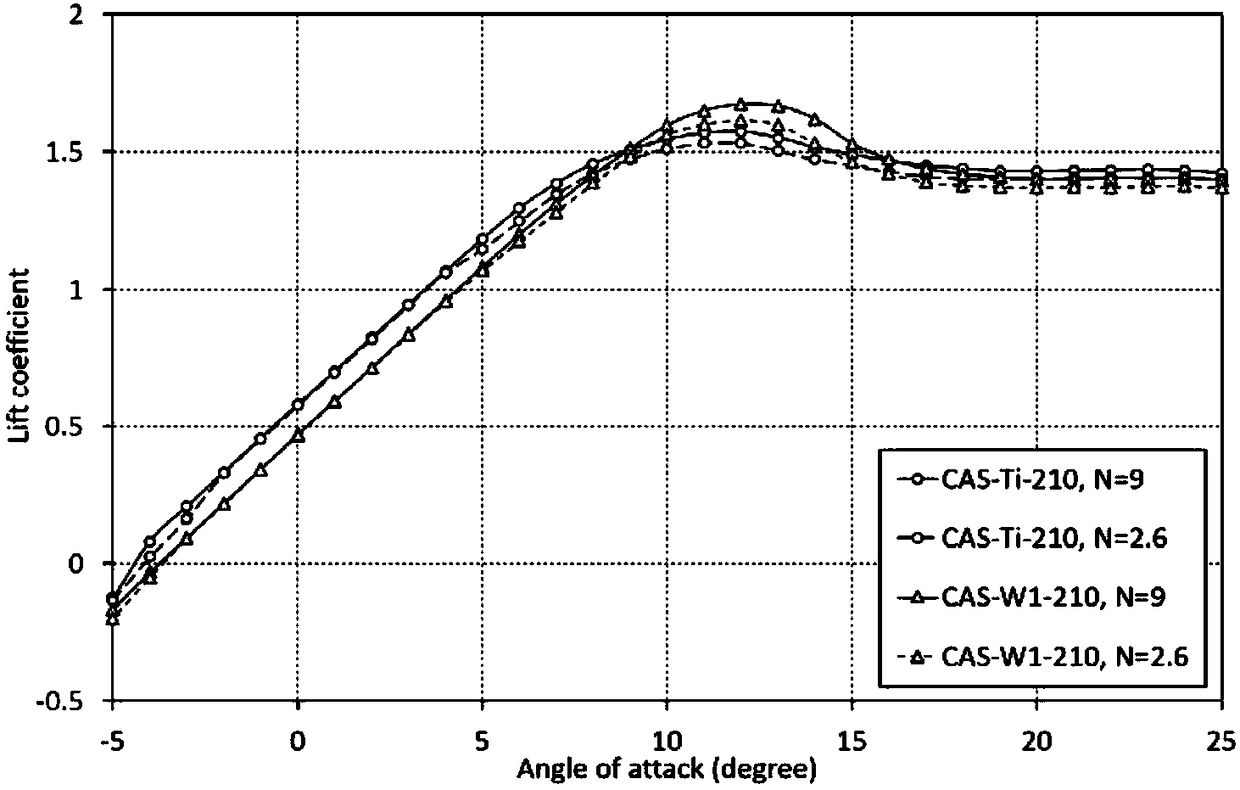

[0064] The flow outside the blade is complex and is the main area for wind energy capture, so the optimization of the outer airfoil is selected as an example of the present invention, and the relative thickness of the target airfoil is set to 21%. The current mainstream models of wind farms in my country are 2MW / 3MW models, so a 2MW blade with a length of 43m is selected as the reference blade. Based on the momentum blade element theory, the operating angle of attack range (3°~7°) and the operating Reynolds number range (3.0E +06~6.0E+06); thus, the design Reynolds number of the airfoil is set to Re=4.5E+06, and the design angle of attack is 5°. Low turbulence intensity inflow conditions (<0.1%) are usually used in airfoil design and test tests. However, when operating at rated wind speeds and above, the free flow t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com