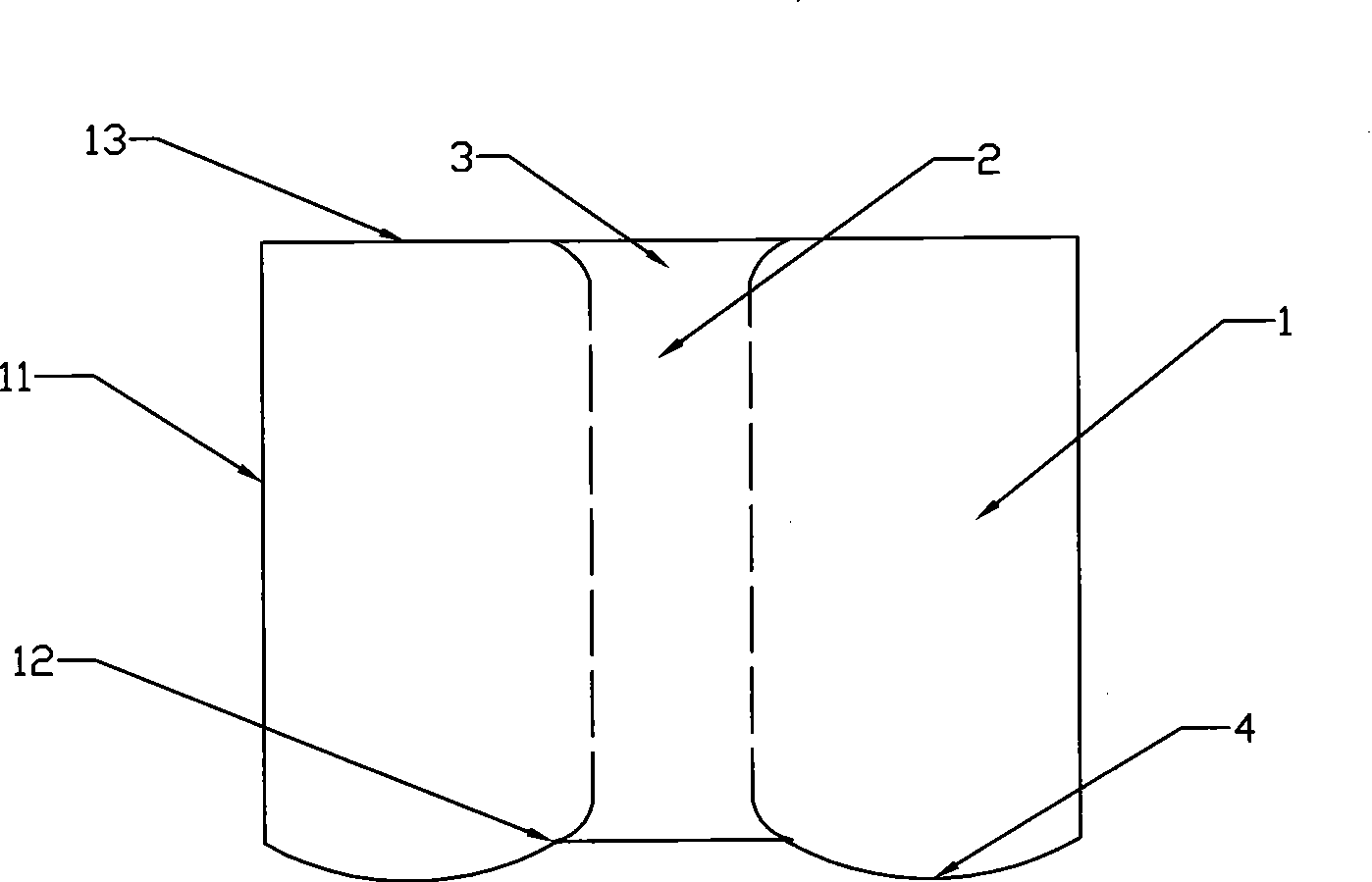

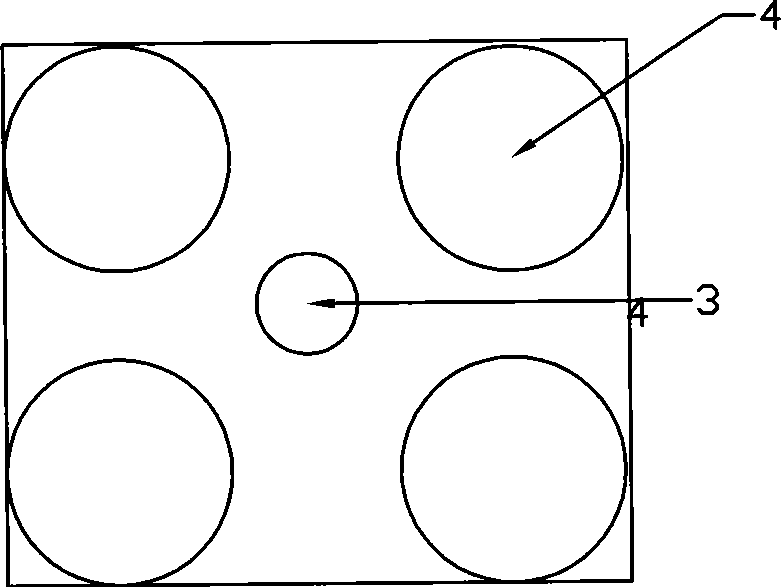

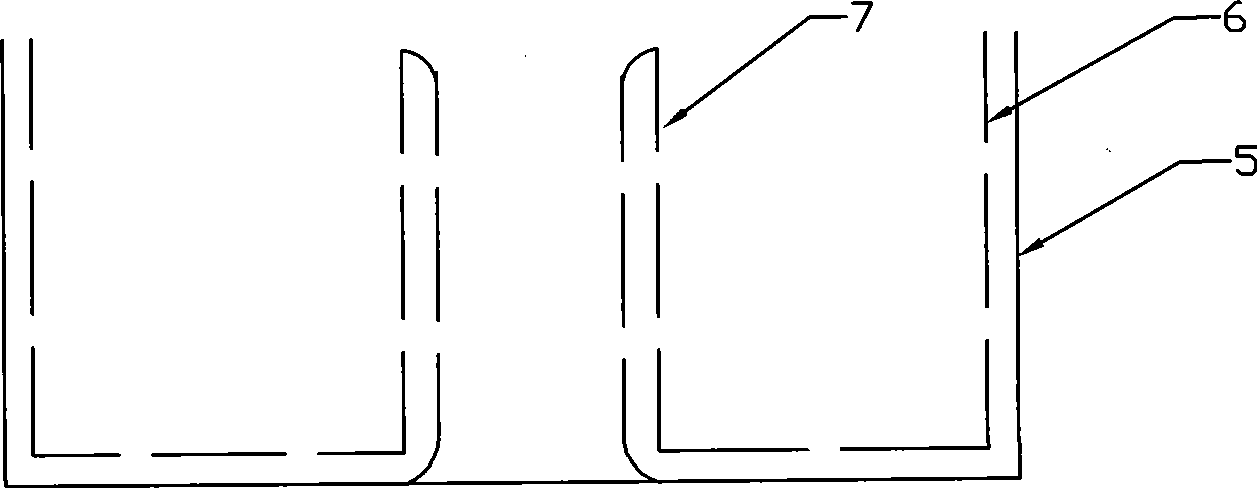

Light component for cast-in-situ hollow floor

A hollow floor and component technology, applied in the direction of building components, applications, floors, etc., can solve the problems of low manufacturing efficiency, poor thermal insulation and heat insulation effects, and reduced material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] One component is as follows, Portland cement, iron aluminate cement, fly ash, early strength agent, water reducing agent, suspending agent, diffusing agent, foaming liquid and foam stabilizer, and its weight percentage is respectively 4%, 57%, 32%, 0.65%, 2.46%, 0.85%, 0.92%, 0.72%, 1.4%, the early strength agent is triethanolamine composite early strength agent, and the water reducing agent is methylnaphthalenesulfonic acid formaldehyde condensate The sodium salt of sodium salt, the suspending agent adopts hydrogenated castor oil, the diffusing agent adopts lignosulfonate, the foaming agent adopts petroleum ether, the foam stabilizer adopts dodecyl dimethyl amine oxide, and the foaming agent and water in the foaming liquid The weight percentage of water is 2.8%, and the weight percentage of water and expansion material is 52%. This expansion material makes the floor have the properties of light weight, corrosion resistance, heat preservation, material saving, seepage pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com