Litchi picking flexible combing-shearing mechanism and rolling combing-shearing device

A flexible and lychee technology, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of long picking cycle, fruit rupture, high cost, etc., to reduce sticking, smooth incision, improve accuracy and effectiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

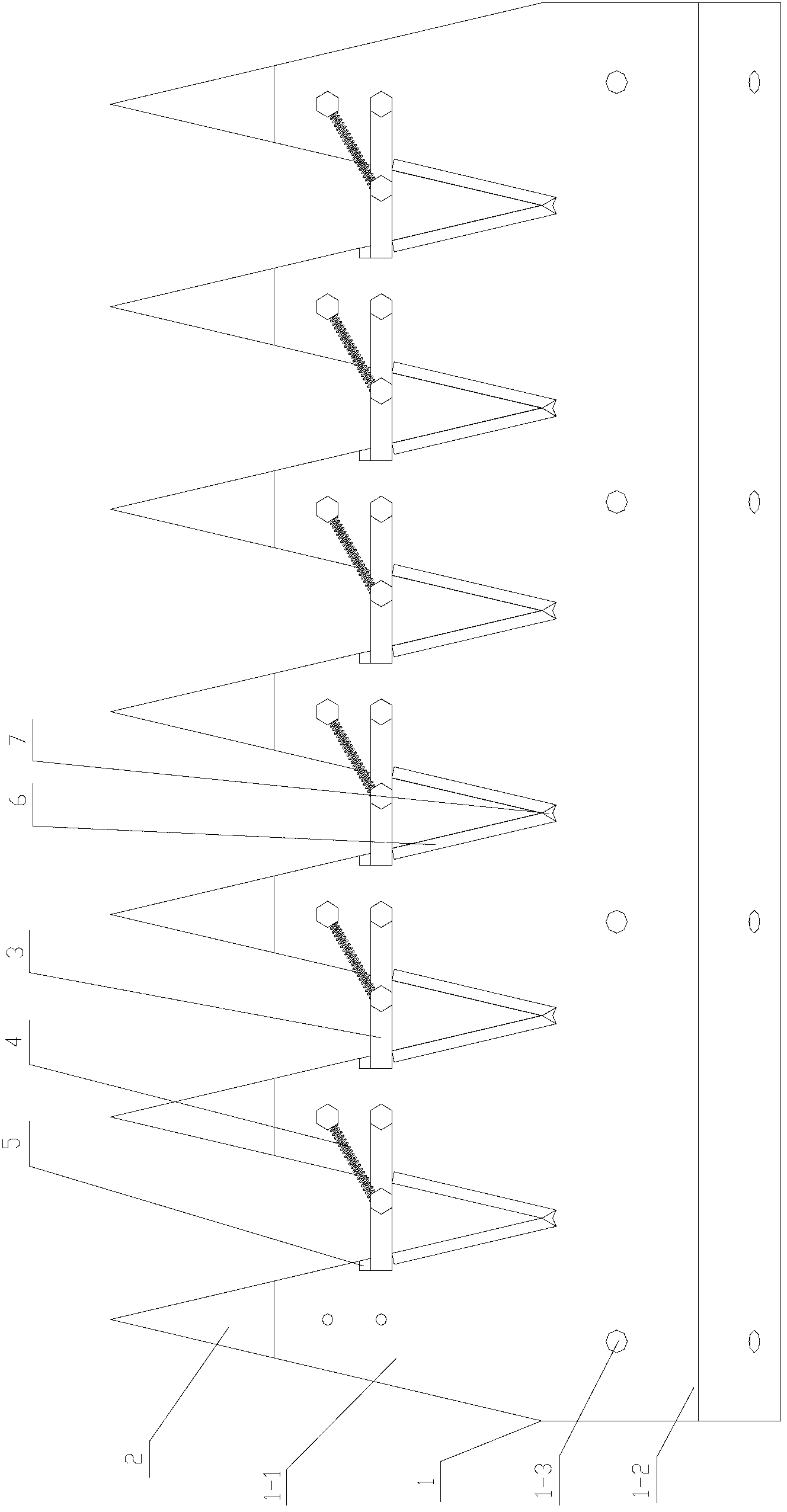

[0024] A kind of litchi picking flexible combing and shearing mechanism of this embodiment, its structure is as follows: figure 1 As shown, it includes a toothed plate 1, a branch assembly, a sorting assembly and a cutting assembly. The branch assembly includes a plurality of conical rubber blocks 2, and each conical rubber block is respectively arranged on each tooth 1-1 on the toothed plate. At the end, a sorting assembly is provided in the middle of any two adjacent teeth on the toothed plate, and a cutting assembly is provided at the root of any two adjacent teeth on the toothed plate. Wherein, the function of the branching component is to separate the lychee branches and guide the branches into the tooth gaps of the toothed plates without damaging the lychee fruit, and the conical rubber block can be selected from a hard elastic material.

[0025] The sorting assembly includes a thin-walled baffle 3, a return spring 4 and a limit block 5. One end of the thin-walled baffle...

Embodiment 2

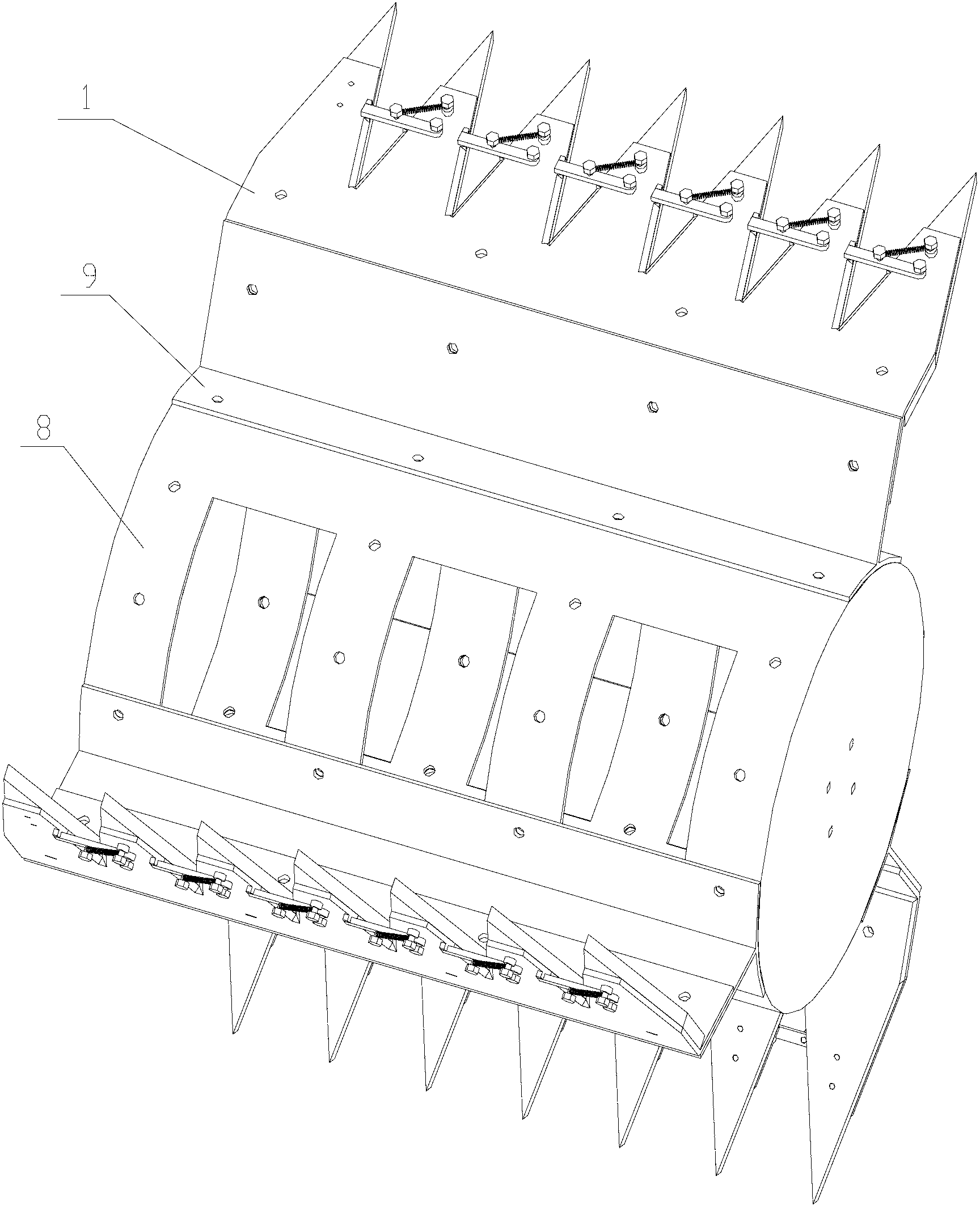

[0032] In this embodiment, a rolling combing and shearing device with a flexible combing and shearing mechanism for litchi picking has a structure such as figure 2 Shown, comprise flexible combing and shearing mechanism (flexible combing and shearing mechanism is the flexible combing and shearing mechanism described in embodiment 1, and its specific structure is as follows figure 1 As shown), drum 8 and mounting support 9, at least one mounting support is provided on the outer surface of the drum, and the flexible combing and shearing mechanism is fixed on the outer surface of the drum through the mounting support; the radial section of the mounting support is "herringbone" , the bottom plate of the mounting support is locked and connected with the side of the drum through bolts, and the toothed plate in the flexible combing mechanism is fixedly connected with the top plate of the mounting support through bolts.

[0033] In this embodiment, as a preferred solution, there are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Hem length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com