Tracking and trimming means of automatic edge sealing machine

An edge banding machine and edge trimming technology, which is applied to wood processing appliances, household components, manufacturing tools, etc., can solve the problems of easily damaged No. 1 cylinder, easily scratched hands and clothes, asynchronous movements, etc. Ensure milling quality and stable center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

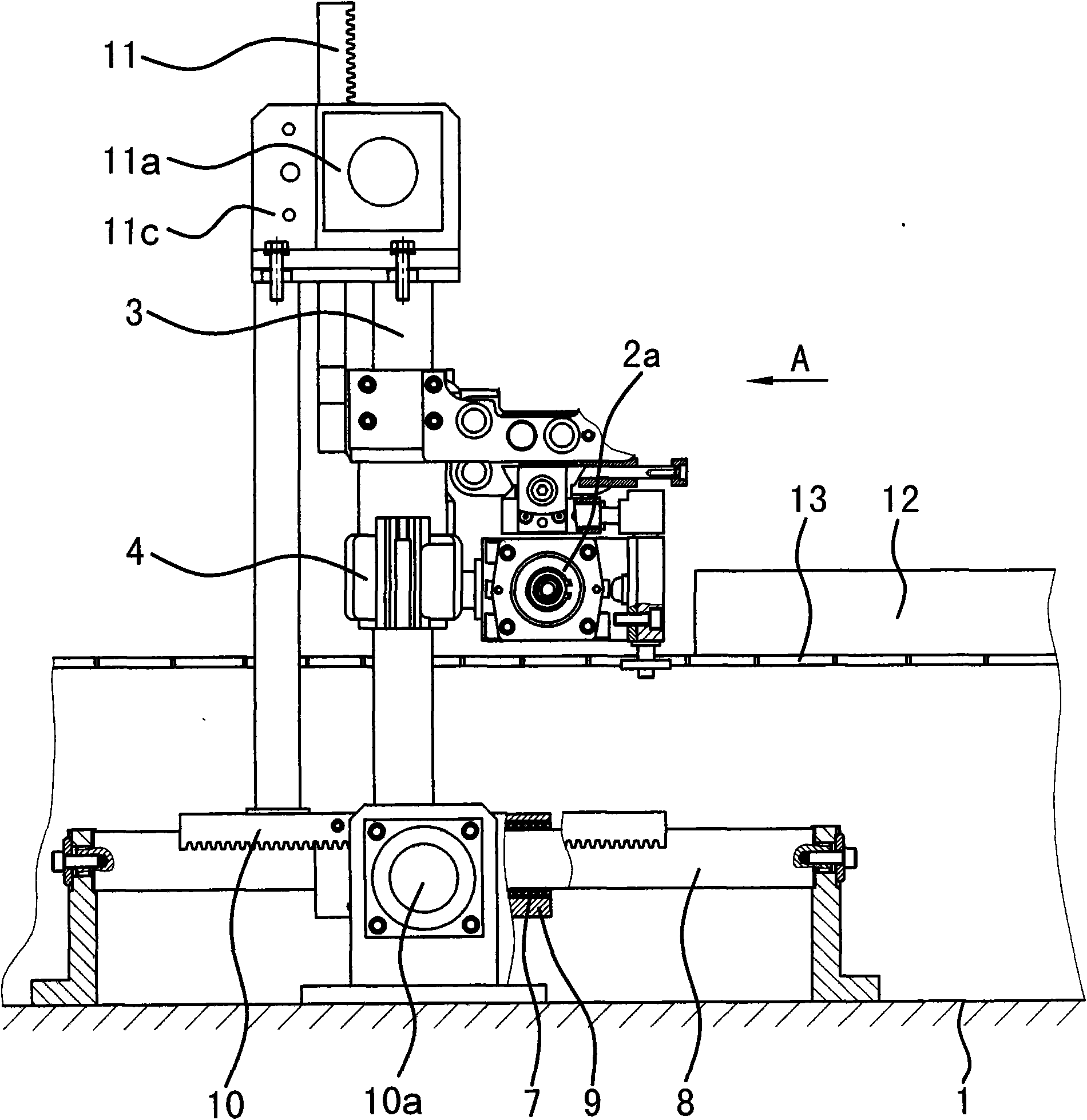

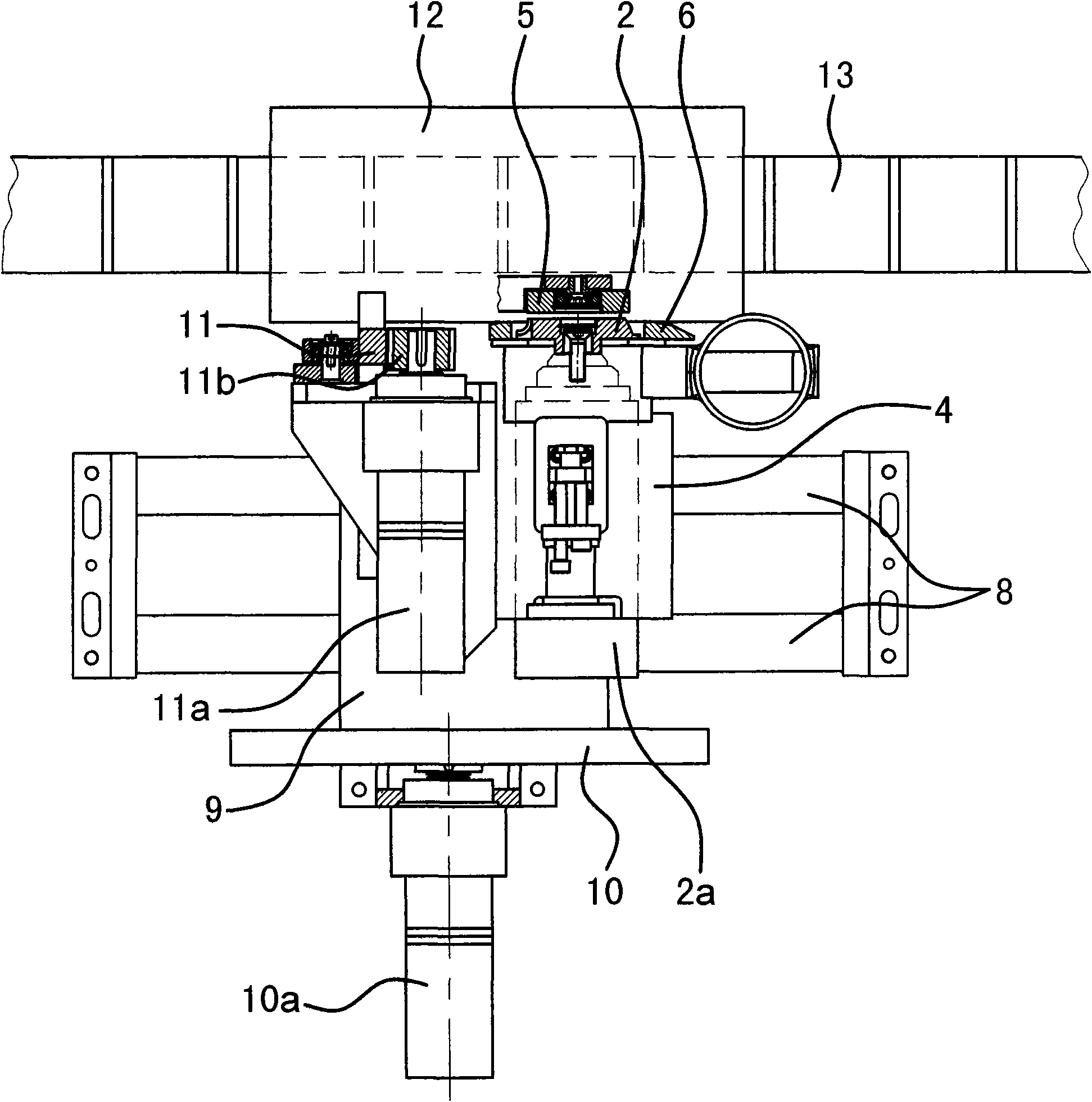

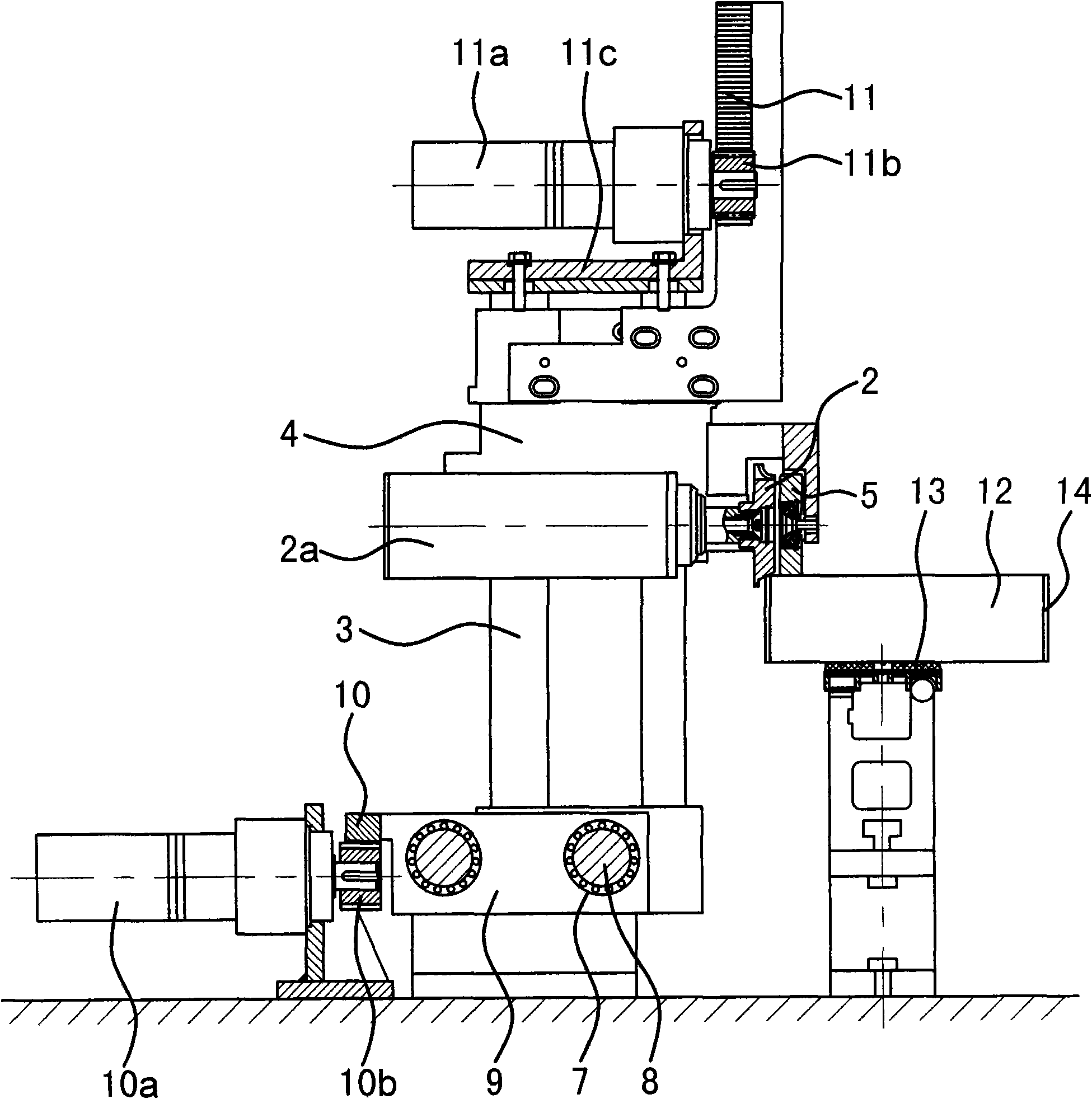

[0027] Such as figure 1 , figure 2 As shown, the tracking and trimming device of the automatic edge banding machine is located behind the automatic edge banding machine, including a milling cutter 2 driven by a motor 2a and a frame 1, and a horizontal horizontal axis 8 is fixed on the frame 1 , the horizontal shaft 8 is externally connected with the translation sliding seat 9, and one side of the translation sliding seat 9 is fixedly connected to the horizontal rack 10, and the moving direction of the horizontal rack 10 is parallel to the axial direction of the horizontal shaft 8, and the horizontal rack 10 is connected with the motor two The gear two 10b driven by 10a meshes with each other, the vertical shaft 3 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com