Point contact shape correcting method of Niemain worm gear

A technology of point contact and worm gear, which is applied to components with teeth, belts/chains/gears, hoisting devices, etc., can solve problems such as unintuitive effect of shape modification, difficult shape modification, and complicated Niemann worm drive. Achieve the effect of increasing service life, improving transmission accuracy, improving sensitivity and tooth surface contact stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

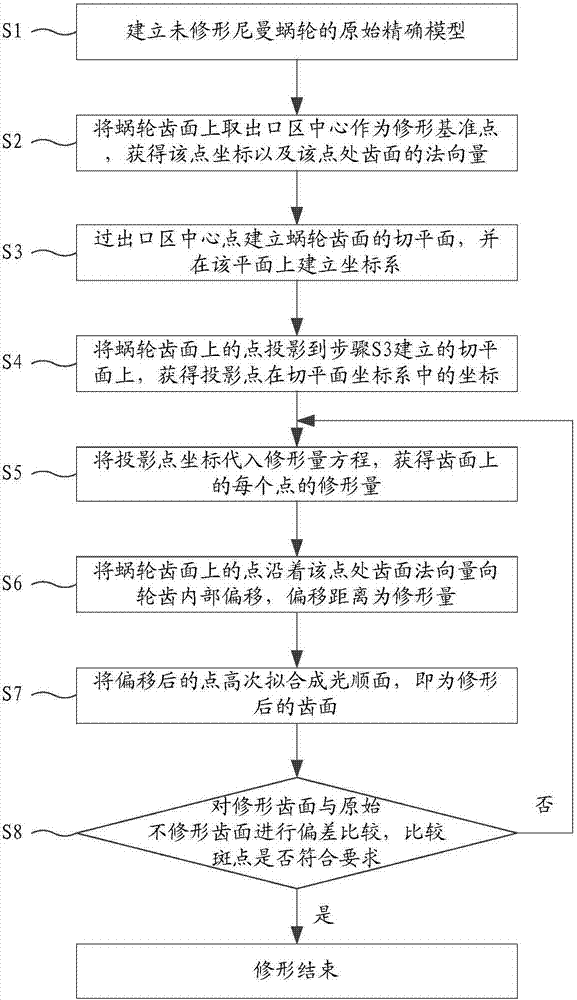

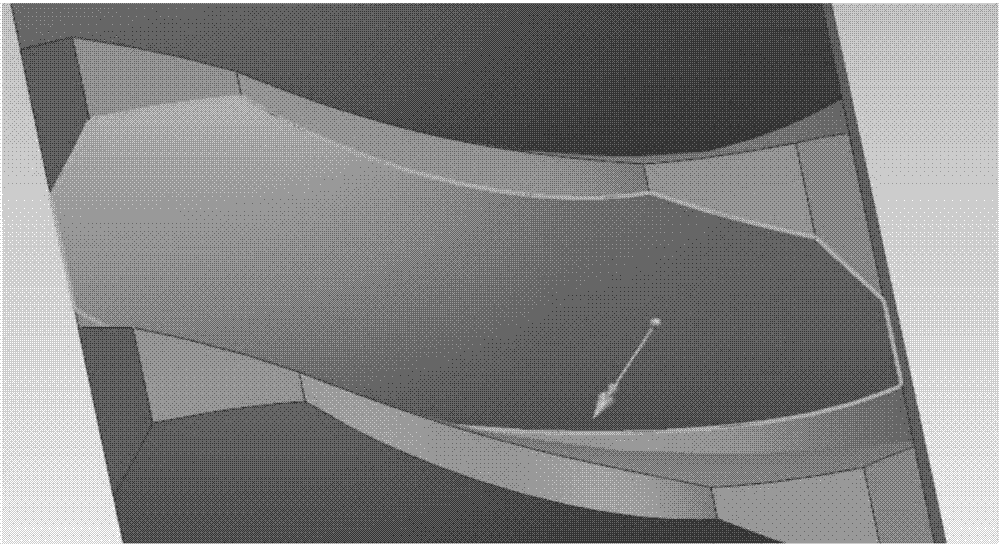

[0061] Such as figure 1 As shown, the present invention adopts UG software to model and modify the shape of the Niemann worm gear, comprising the following steps:

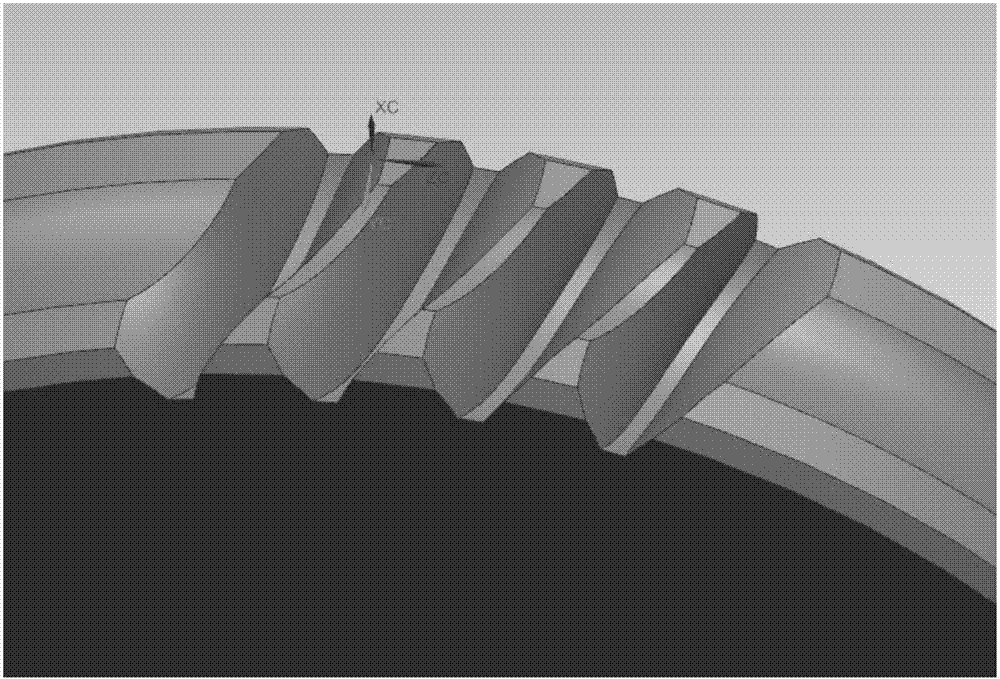

[0062] S1, such as figure 2 As shown, the original accurate model of the unmodified Niemann worm gear was established in the 3D software. The main parameters of the worm pair are as follows:

[0063] The axial modulus of the worm m=10.5mm, the number of worm heads Z 1 =4, the number of worm gear teeth Z 2 =37, worm normal tooth profile angle α n =23°, coefficient of worm addendum height Worm dedendum height factor The lead angle of the helix on the worm indexing cylinder γ=23.8505556°, the radius of the grinding wheel r u =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com