Top-down construction method of large underground structure outer wall

A technology for underground structures and construction methods, which is applied to underwater structures, infrastructure engineering, buildings, etc., can solve the problems of large friction force on the outside of the outer wall, heavy workload, and large verticality deviation, so as to improve the work efficiency of pouring concrete , good social benefits, and the effect of ensuring the quality of molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

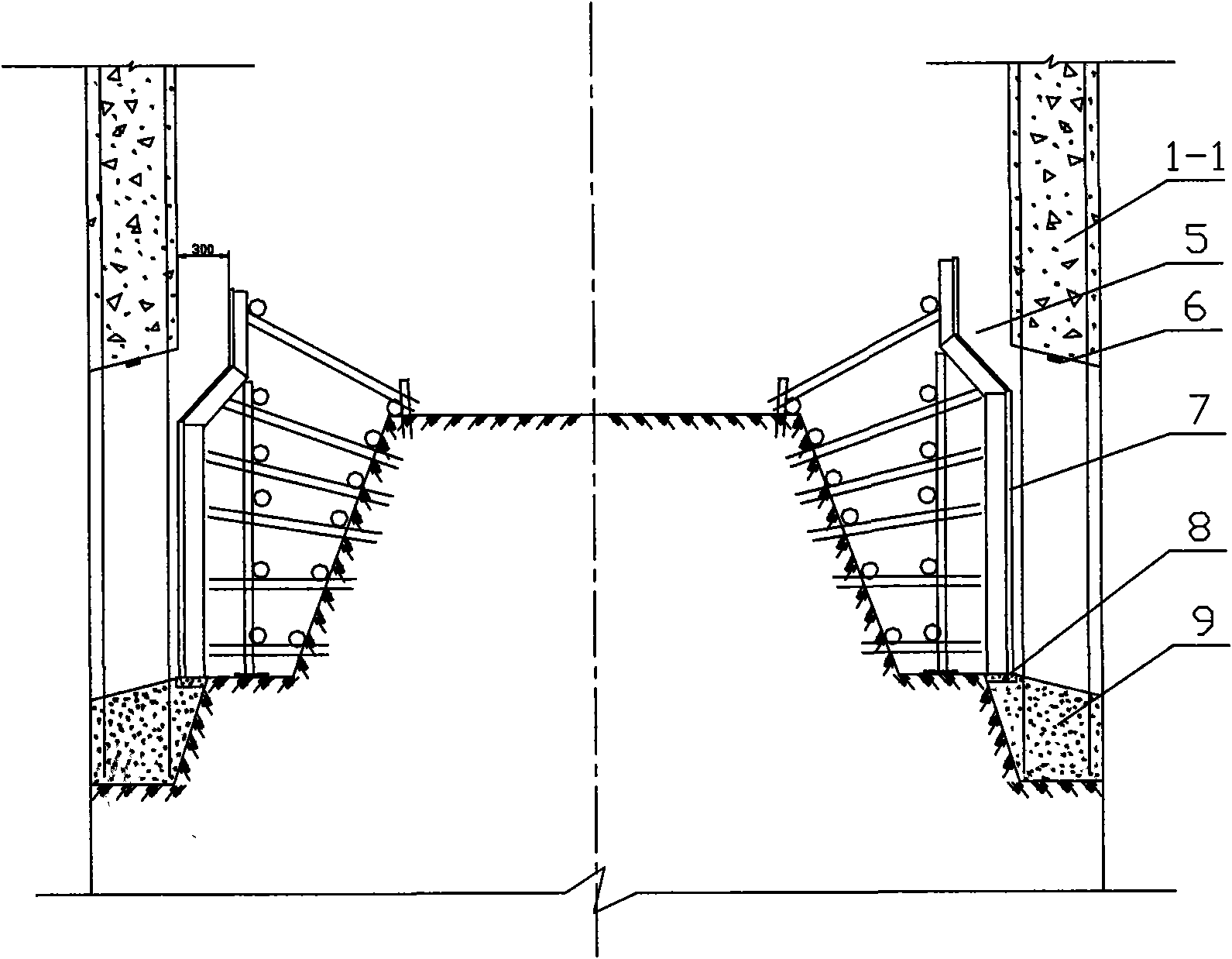

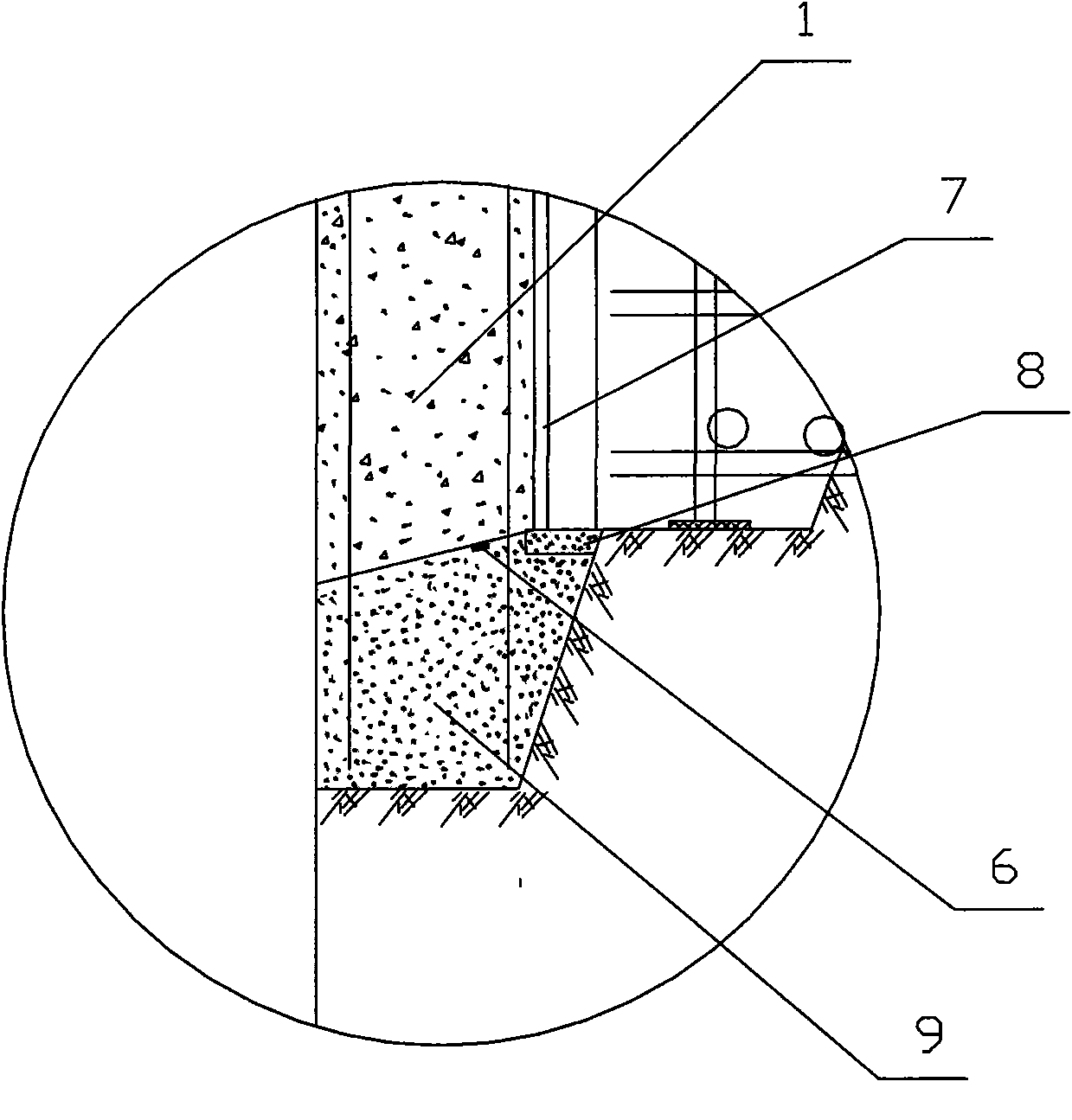

[0035] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

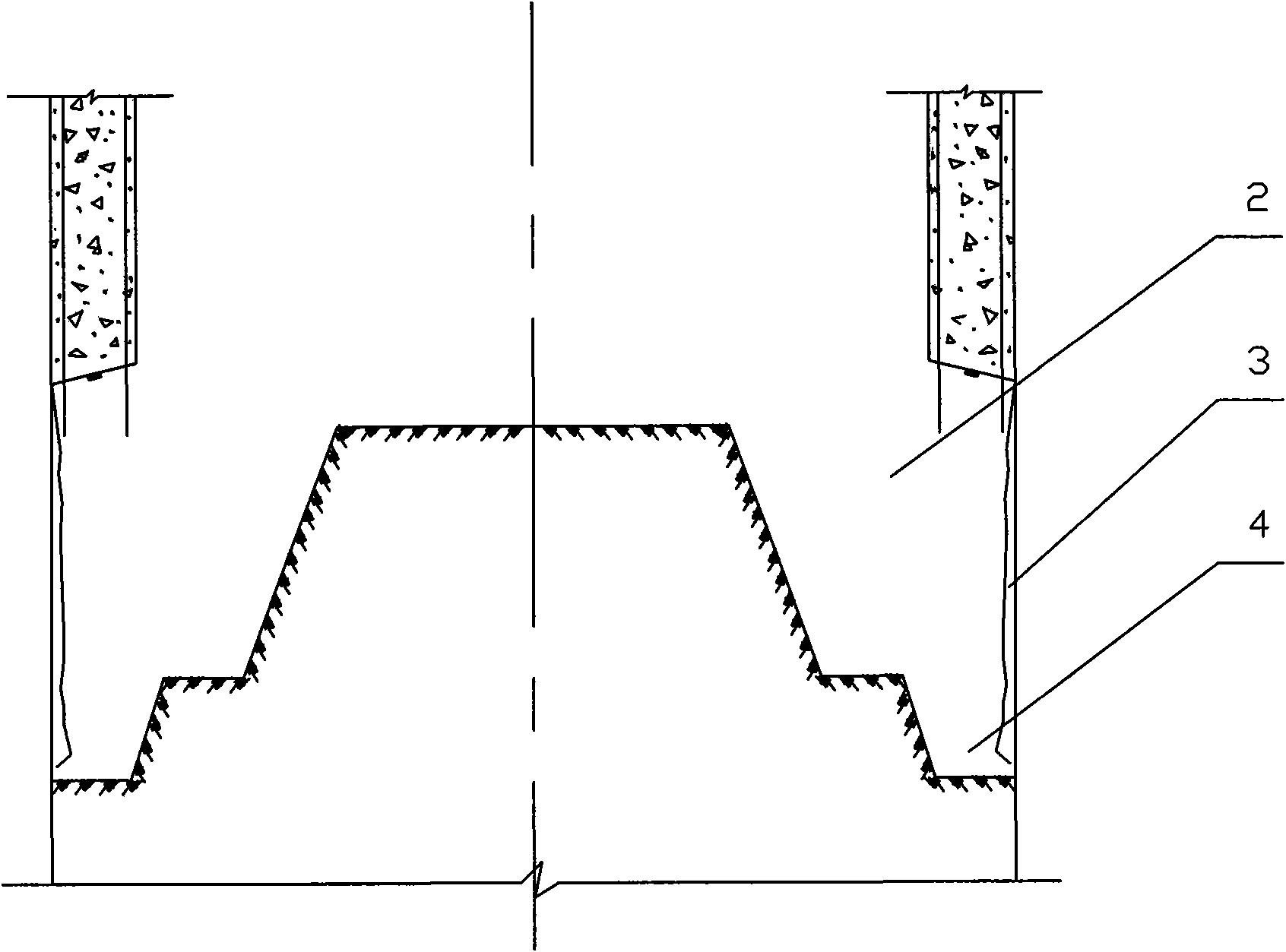

[0036] Taking the cyclone sedimentation tank constructed in a water treatment system as an example, because the foundation bearing capacity of the project is very high and the friction coefficient of the soil is relatively large, the outer wall of the cyclone sedimentation tank passes through the gravel layer to further increase the outer wall and Due to the friction of the surrounding soil, there is a certain risk in using the previous caisson construction method. Therefore, the outer wall of the above-mentioned cyclone sedimentation tank is constructed by adopting a reverse construction method for the outer wall of a large underground structure provided by the present invention. The construction process is as follows:

[0037] ①Constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com