Garment layout tailoring method

A technology of ready-made garments and fabrics, applied in the field of garment production, to achieve the effects of reducing waste, improving grades, and improving perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

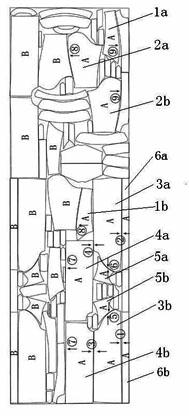

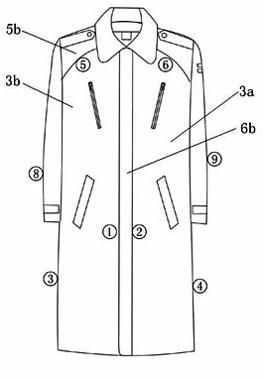

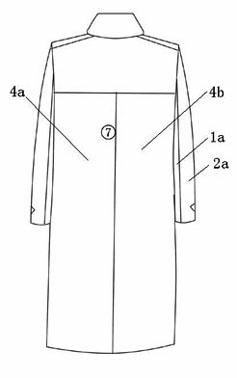

[0018] The method of typesetting and cutting for garment making in the present invention is illustrated with the process of making typesetting and cutting for coat. According to the width and size of the fabric, according to the specifications of each piece of the garment, use the garment CAD software for typesetting, and the application software used is Gerber Garment CAD. Print the layout map into a board, then place the board on the coded fabric, and cut it according to the board. When typesetting, place the exposed and obvious joints on the same or similar warp yarns of the fabric. Such as figure 1 Shown is the pattern-making diagram of the coat. In order to make full use of the fabric, two garment pieces are cut from the same fabric length, that is, A piece and B piece. Taking piece A as an example, the joint seam ② of the front panel 3a and the door 6a and the joint seam ① of the front panel 3b and the door 6b are located on the similar warp yarns, the joint seam ④ of...

Embodiment 2

[0020] Such as Figure 4 Shown is the plate-making diagram of the trousers. In order to make full use of the fabric, four pieces of clothing are cut from the same fabric length, namely A piece, B piece, C piece and D piece. Taking the A piece as an example, the joining seam (1) of the trousers front panel 7a and the trousers back panel 8b and the joining seam (2) of the trousers front panel 7a and the trousers back panel 8b are located on similar warp yarns. The joining seam (3) of the trousers front panel 7b and the trousers front panel 8a and the joining seam (4) of the trousers front panel 7b and the trousers back panel 8a are located on the similar warp yarns, and the joining seam (5) of the side bucket stop 9a and the trousers front panel 7a is located at On the same warp thread, the joining seam (6) of the side bucket catch 9b and the trousers front panel 7b is located on the same warp thread.

[0021] The garments made according to the above typesetting method are as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com