Automobile covering element spray coating method

A technology for coating parts and surfaces of automobiles, which is applied in the direction of surface coating liquid devices, coatings, and surface pretreatment, etc., which can solve the problems that cannot meet the requirements of large-scale production of automobiles, and achieve the goal of speeding up the progress of spraying, shortening the cycle, and ensuring The effect of apparent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

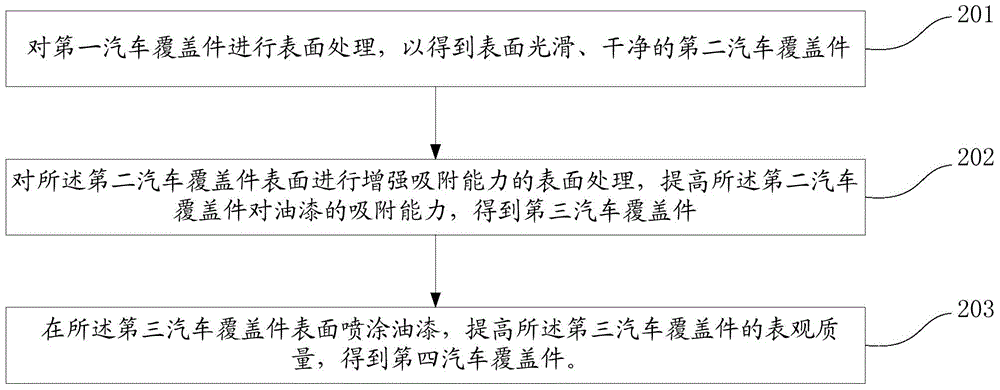

[0039] Such as figure 1 Shown, the embodiment of the present invention provides a kind of method of spraying automobile cover part, and this method comprises:

[0040] In step 201: surface treatment is performed on the first automobile cover to obtain a smooth and clean second automobile cover;

[0041] In step 202: performing surface treatment on the surface of the second automobile cover to enhance the adsorption capacity, improving the adsorption capacity of the second automobile cover to paint, and obtaining a third automobile cover;

[0042] In step 203: spraying paint on the surface of the third automobile panel to improve the apparent quality of the third automobile panel to obtain a fourth automobile panel.

[0043] The present invention enhances the adsorption ability of the surface of the second car cover to the paint by performing surface treatment to enhance the adsorption capacity of the second car cover, so that the paint can be effectively adsorbed on the surfa...

Embodiment 2

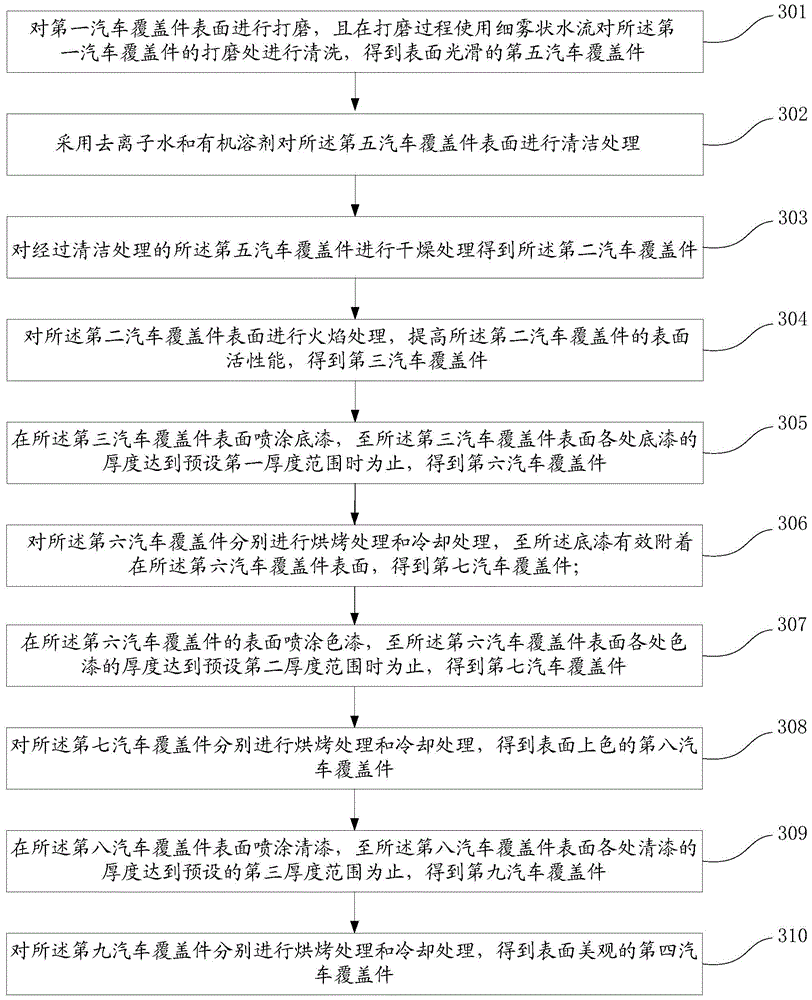

[0065] Such as figure 2 As shown, a method for spraying automobile panels provided by the embodiment of the present invention is used for spraying automobile panels made of carbon fiber composite materials, including:

[0066] In step 301, the surface of the first car cover is polished, and the polished part of the first car cover is cleaned with fine mist water flow during the grinding process to obtain a fifth car cover with a smooth surface.

[0067] Wherein, the grinding of the surface of the first automobile cover needs to be carried out in a confined space, and before grinding, the first automobile cover needs to be fixed on the inner bushing, the surface of the first automobile cover is kept on the top, and there is no If any part is blocked, then use a water gun to rinse the surface of the first car cover to remove the dust on the surface of the first car cover, and then use a dry cloth to wipe off the water on the surface of the first car cover. During the grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com