Nickel-zinc secondary seal cylindrical alkaline battery with shell as cathode and manufacturing method for nickel-zinc secondary seal cylindrical alkaline battery

A technology for secondary sealing and alkaline batteries, which is applied in the direction of dry batteries, battery electrodes, battery pack components, etc. It can solve the problems that the battery appearance is difficult to meet the battery standard requirements, the unfavorable battery capacity life extension, and the battery production efficiency decrease. Achieve the effect of cost reduction, reasonable structure and convenient procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The present invention will be further described below using the accompanying drawings and examples.

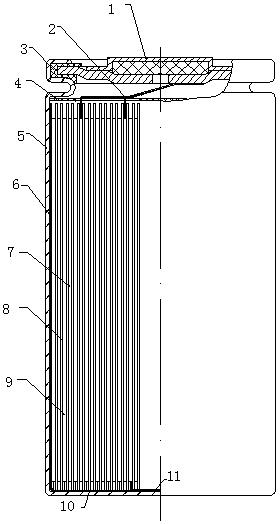

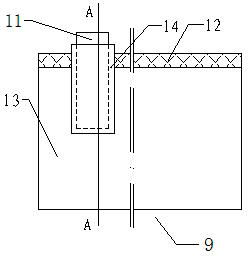

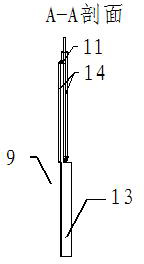

[0032] refer to figure 1 , the zinc-nickel secondary sealed cylindrical alkaline battery of the present invention whose outer shell is the negative electrode includes a battery shell 5, and the upper end of the battery shell 5 is insulated and sealed and fixedly connected with the nickel-plated cap 1 through a sealing ring 3. In the battery casing 5, an electrode group wound by a tinned red copper tab negative electrode piece 9, a diaphragm 8 and a nickel tab positive electrode piece 7 is arranged, and a tinned red copper tab negative electrode piece 9 and a nickel tab positive electrode piece are arranged. Between 7 is a diaphragm 8, and the outer ring of the pole group with tin-plated red copper lug negative plate 9 is wrapped with a protective film 6. An insulating gasket 4 is placed on the upper end of the pole group and the positive nickel tab 2 passes through the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com