Patents

Literature

58results about How to "Comprehensive performance testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

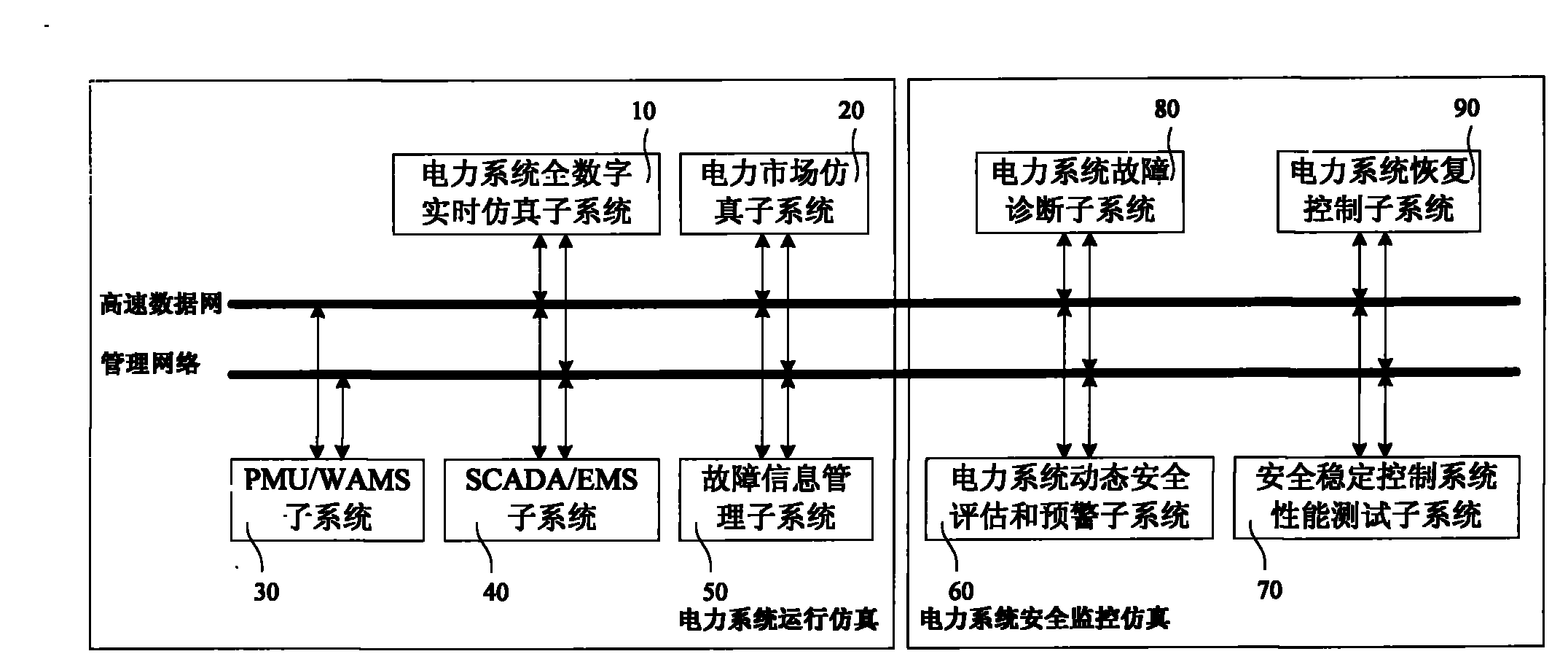

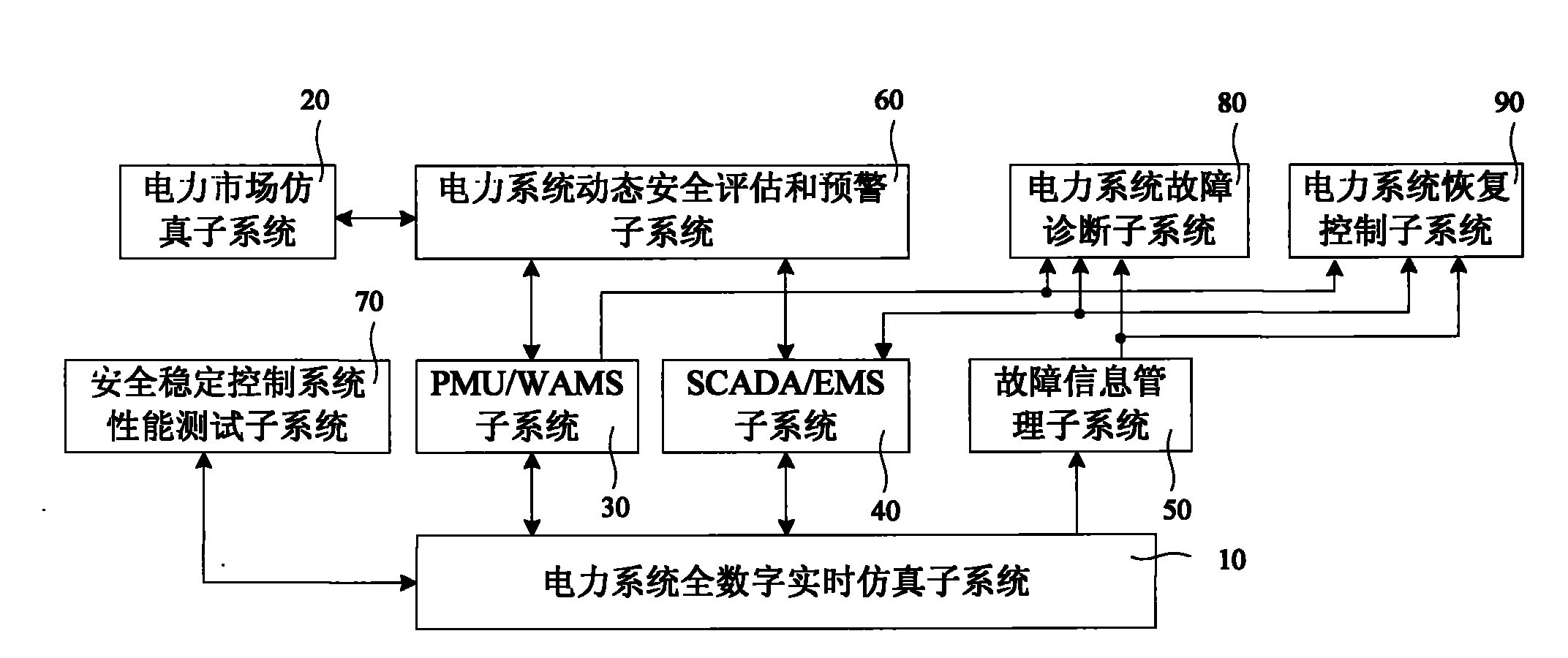

Operation and safety monitoring simulation system for power system

ActiveCN101944766AComprehensive effectComprehensive performance testingCircuit arrangementsSpecial data processing applicationsElectricity marketPower system scheduling

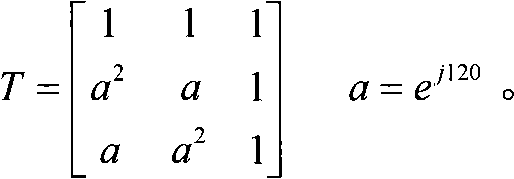

The invention relates to an operation and safety monitoring simulation system for a power system, which comprises a power system full digital real-time simulation subsystem used for simulating the operation of a large-scale power system in real time and providing simulation data to other subsystems, a power market simulation subsystem used for simulating and training power market transaction, a PMU / WAMS subsystem used for carrying out real-time dynamic monitoring and analysis on a simulated power system, an SCADA / EMS subsystem used for monitoring and analyzing the simulated power system, a fault information management subsystem used for managing and comprehensively utilizing fault information, a power system dynamic safety assessment and early warning subsystem used for carrying out safety assessment and early warning on the current power system and carrying out safety verification on the operation mode of a future plan, a safety and stability control system performance test subsystem used for testing the performance of a protective relay device, a power system stabilizer (PSS) and other automated equipment as well as a safety and stability control system and equipment, a power system fault diagnosis subsystem used for carrying out on-line diagnosis and intelligent safety alarming on the fault of the simulated power system and providing a dispatching control decision under the fault condition, and a power system recovery control subsystem used for recognizing the state of the fault of the simulated power system, searching and inferring the power supply path of an outage region and providing a power grid recovery control strategy. The system can simulate the operation of a large-scale power grid in real time, and can be used for searching and comprehensively testing the technology and software of various power systems in dispatching, operation, control and other aspects.

Owner:CHINA ELECTRIC POWER RES INST +1

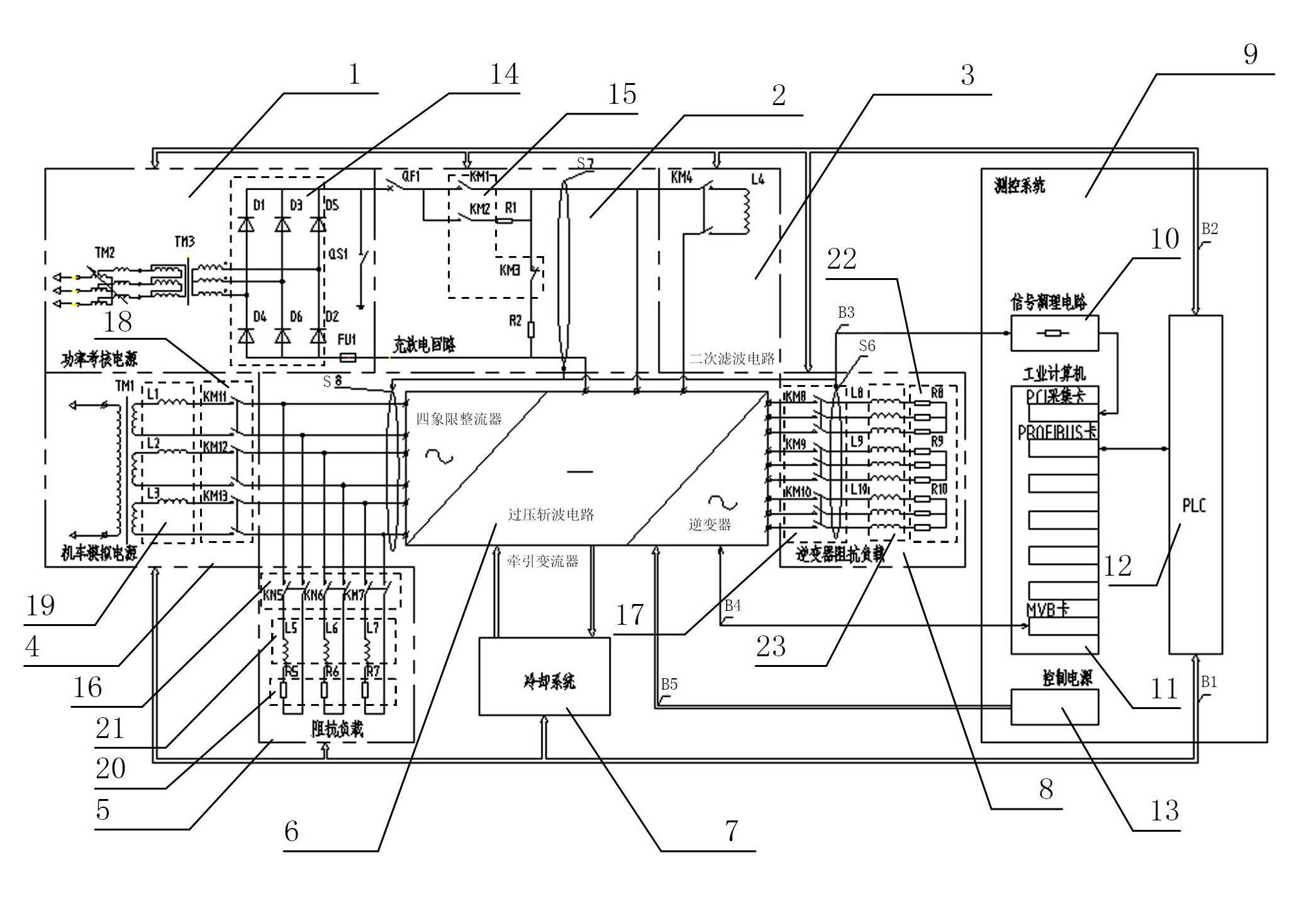

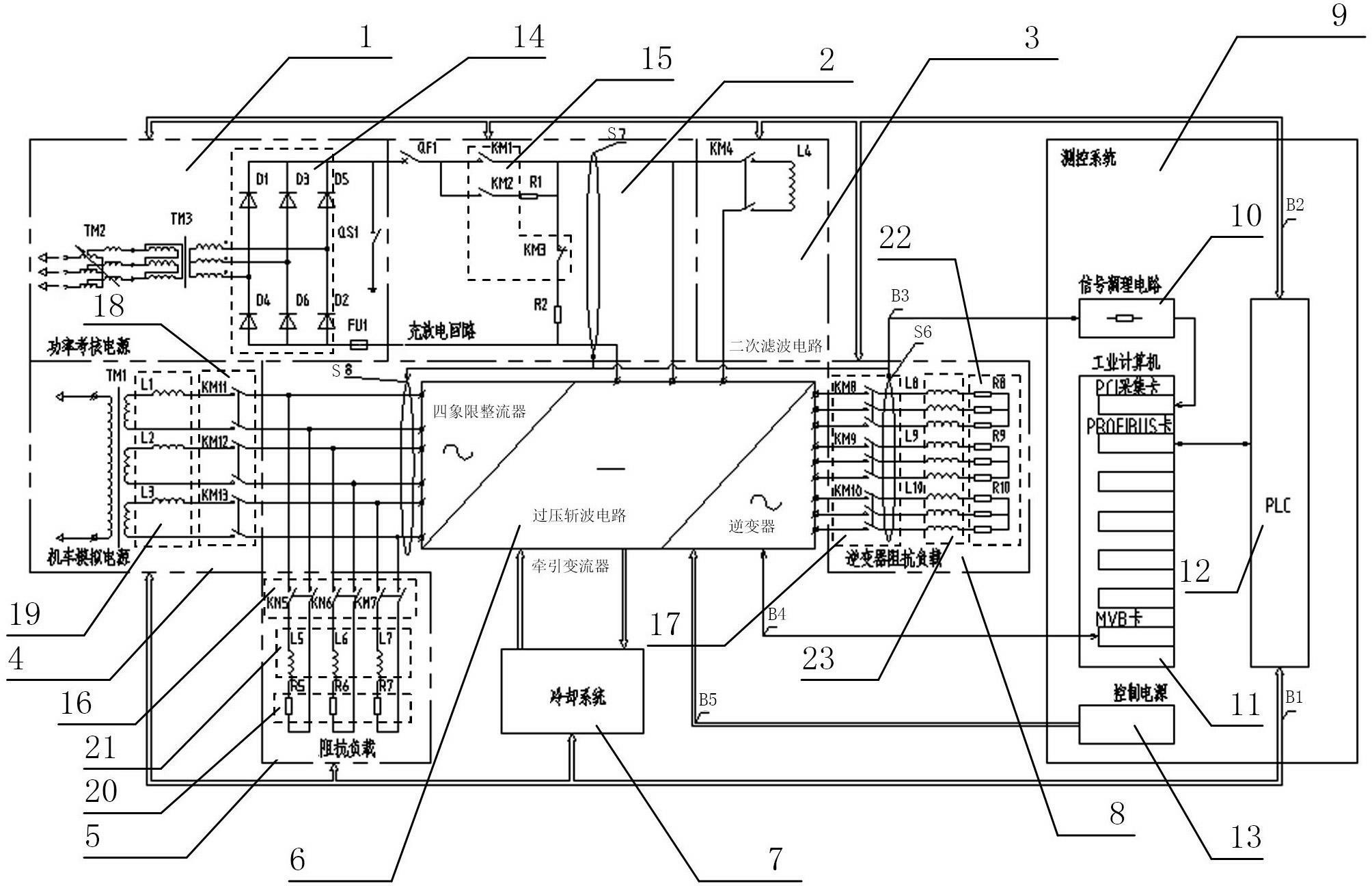

Locomotive traction converter test apparatus and method thereof

ActiveCN102435899AReduce wiring timeComprehensive performance testingPower supply testingPower inverterCharge and discharge

The invention discloses a locomotive traction converter test apparatus and a method thereof. The apparatus comprises: a power assessment power supply, a charging and discharging loop, a secondary filter circuit, a locomotive simulation power supply, an impedance load, a traction converter, a cooling system, an inverter impedance load and a measurement and control system. The power assessment power supply is connected with the charging and discharging loop. The charging and discharging loop is connected with the secondary filter circuit. The charging and discharging loop and the secondary filter circuit are connected with the traction converter respectively. An output terminal of the locomotive simulation power supply is connected with the impedance load and the traction converter respectively. The output terminal of the traction converter is connected with the inverter impedance load. The traction converter is connected with the cooling system and the measurement and control system respectively. The test method comprises: a chopper loop test, a light load joint debugging test and a power assessment test of the traction converter. By using the technical scheme in the invention, the comprehensive performance test can be performed to the locomotive traction converter. A structure is simple. An operation is simple. And environmental protection and energy saving can be achieved.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

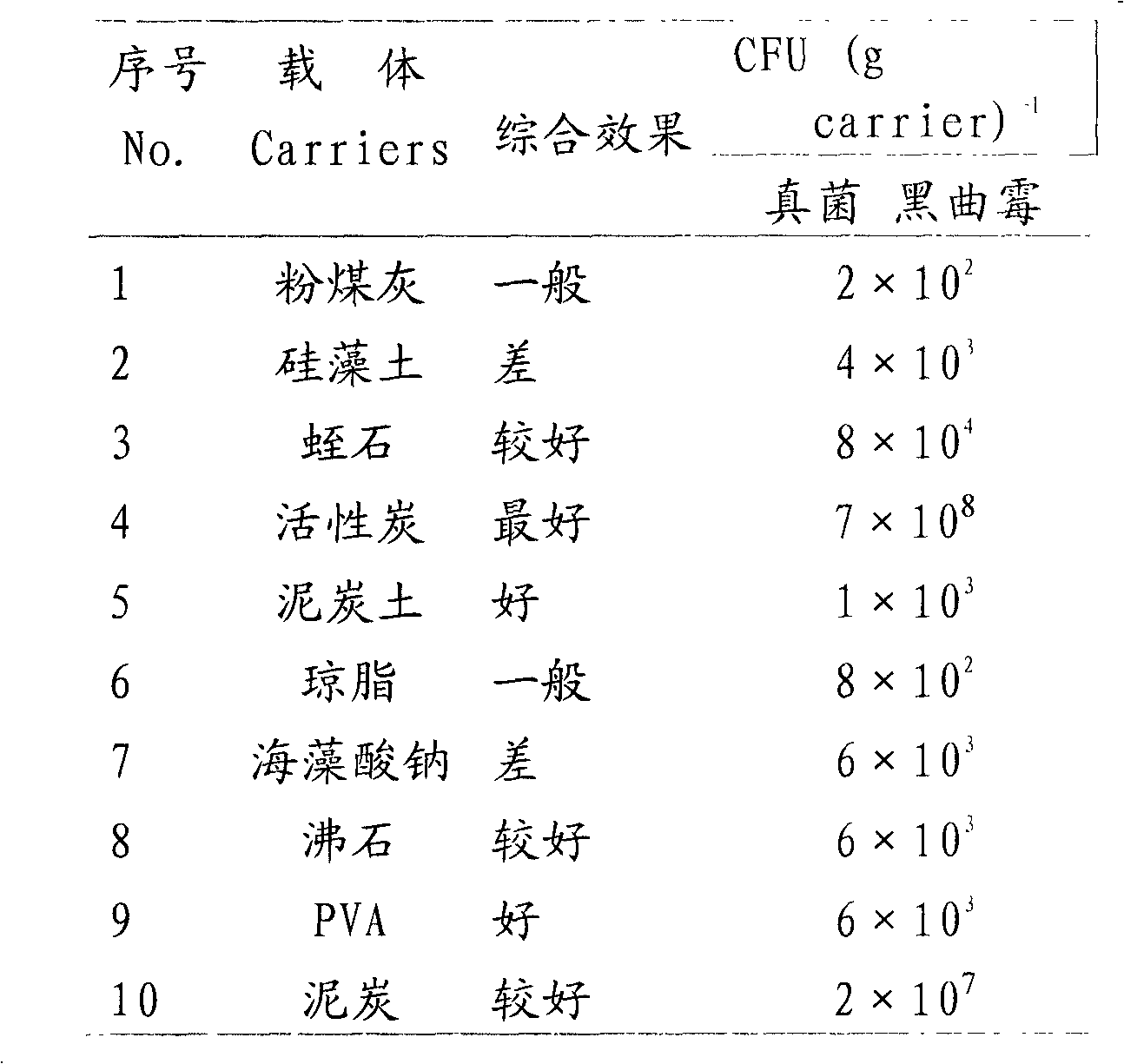

Method for treatment of organophosphorus pesticide wastewater by immobilized microorganisms

InactiveCN103102015ANo secondary pollutionLow priceBiological water/sewage treatmentActivated carbonMicroorganism

The invention relates to a method for treatment of organophosphorus pesticide wastewater by immobilized microorganisms. Mainly composed of the processes of strain domestication, carrier preparation, bacterium adsorption and wastewater treatment, the method is characterized by: adsorbing domesticated fungus Aspergillus niger to activated carbon with a diameter of 5-8mml, then putting the prepared activated carbon containing saturated Aspergillus niger into wastewater, with the putting amount of activated carbon accounting for 1% of the wastewater when the CODcr (chemical oxygen demand) of each liter of sewage reaches 200-10000, controlling the temperature at 530DEG C, and performing static immersion for 1-6 days. By using the method to treat the organophosphorus pesticide wastewater, the degradation rate can reach up to 98%.

Owner:白雪

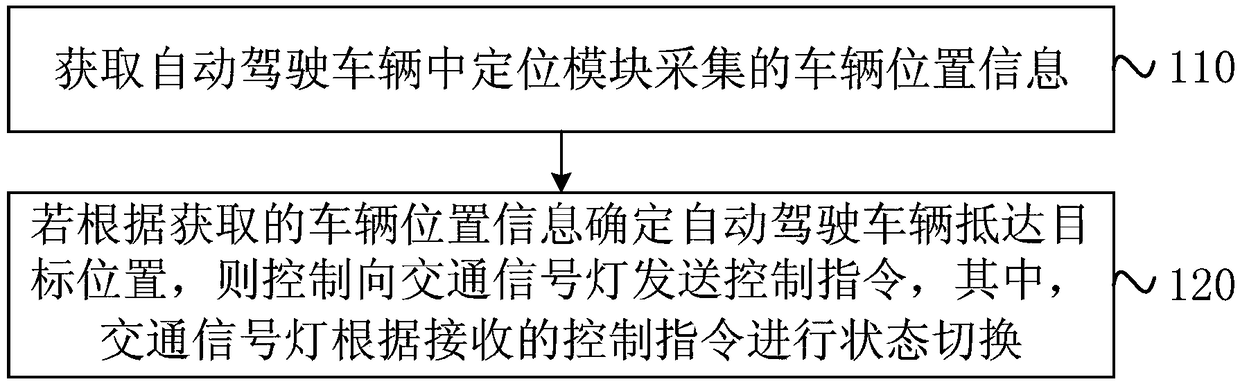

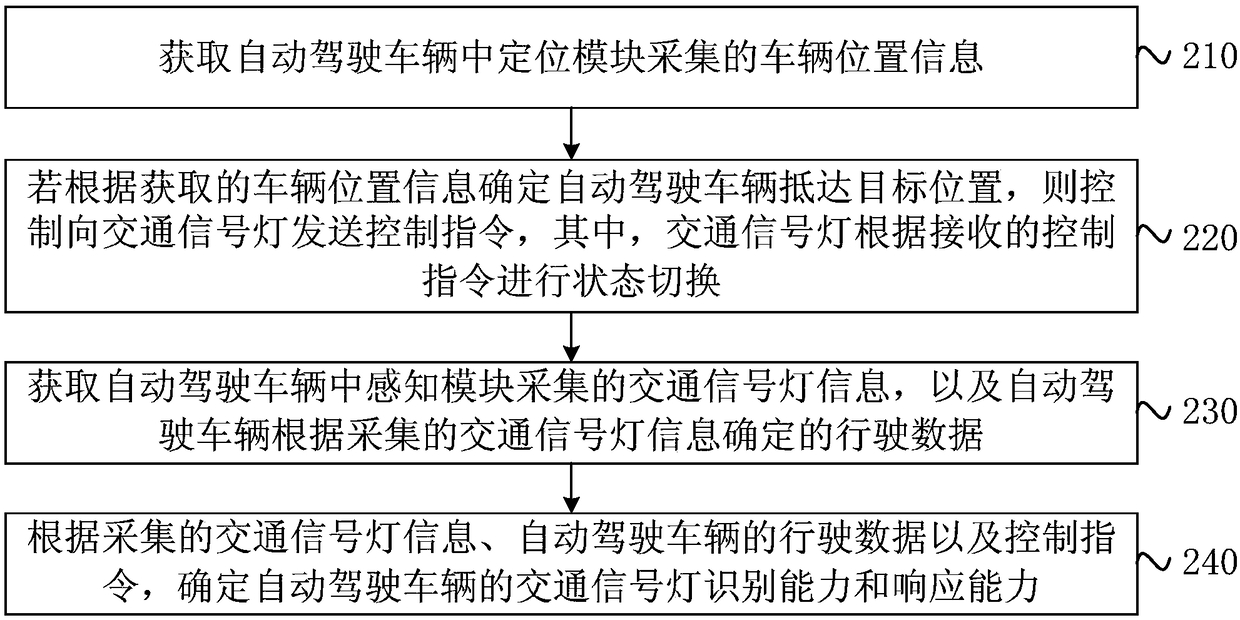

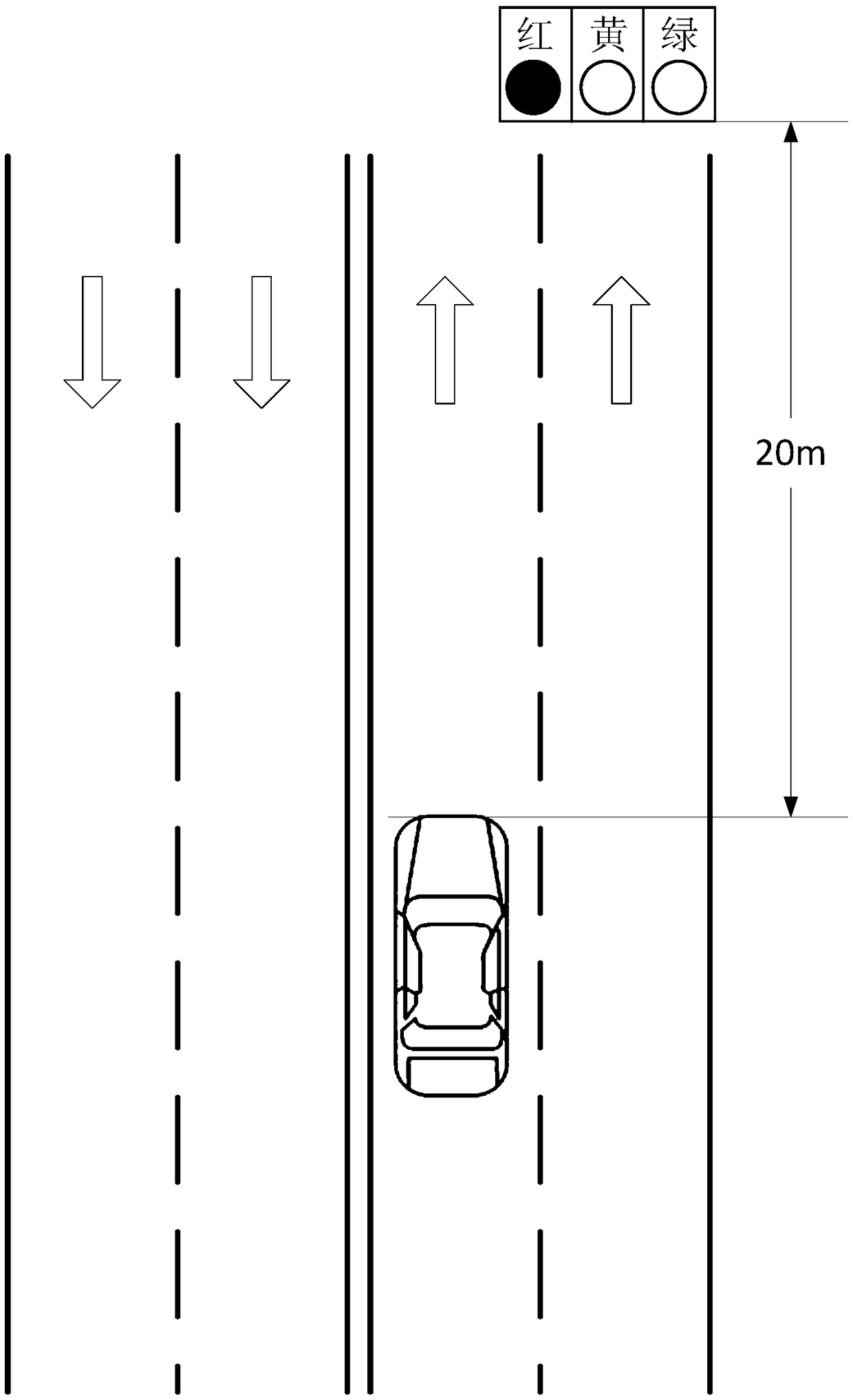

Autonomous vehicle testing method, device, testing equipment and storage medium

PendingCN109064763AComprehensive performance testingImprove accuracyVehicle testingControlling traffic signalsTraffic signalComputer science

The embodiment of the invention discloses an autonomous vehicle testing method, a device, testing equipment and a storage medium. The autonomous vehicle testing method comprises the steps that vehicleposition information collected by a positioning module in an autonomous vehicle is obtained; if it is confirmed that the autonomous vehicle arrives at a target position according to the vehicle position information, a control instruction is sent to a traffic light, wherein the state of the traffic light is switched according to the received control instruction. According to the autonomous vehicletesting method, the device, the testing equipment and the storage medium, through arrangement of the testing triggering condition and switching of the traffic light, the testing need under differentdriving conditions is met, the diversified autonomous vehicle performance test is achieved, and the accuracy of the testing result and testing efficiency are improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Flexible assembly technology of low-voltage motor and assembly line thereof

ActiveCN101951082AEasy to assemblePlay a transitional roleManufacturing dynamo-electric machinesLow voltageEngineering

The invention discloses a flexible assembly technology of a low voltage motor and an assembly line thereof. The assembly process comprises the following steps in sequence: a stator enters an assembly area from the top line of a piece feeding area to start motor assembly, and then enters a pretreatment area from the underline of a primary underline area; the appearance of the motor is subjected to fine treatment in the pretreatment area; the motor enters a primary painting area to paint and dry an end cover from the top line of a primary top line area, and then a fan and an end shield are assembled on line; the motor enters an experimental area from the underline of a secondary underline area; a motor experiment is carried out in a test area, and then the motor enters a perfect area after test permission to be perfectly assembled in the perfect area; the motor enters a secondary painting area to be painted and dried from the top line of a secondary top line area, and then is packaged at the underline of a package area; and after packaging, the motor enters a finished motor storage area to be stored. The time and beat of each assembly link can be flexibly regulated and controlled so as to realize flexible assembly, thus not only reserving the advantage of the assembly line facilitating line production but also meeting the production requirements of various species, small batch and multiple specifications.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

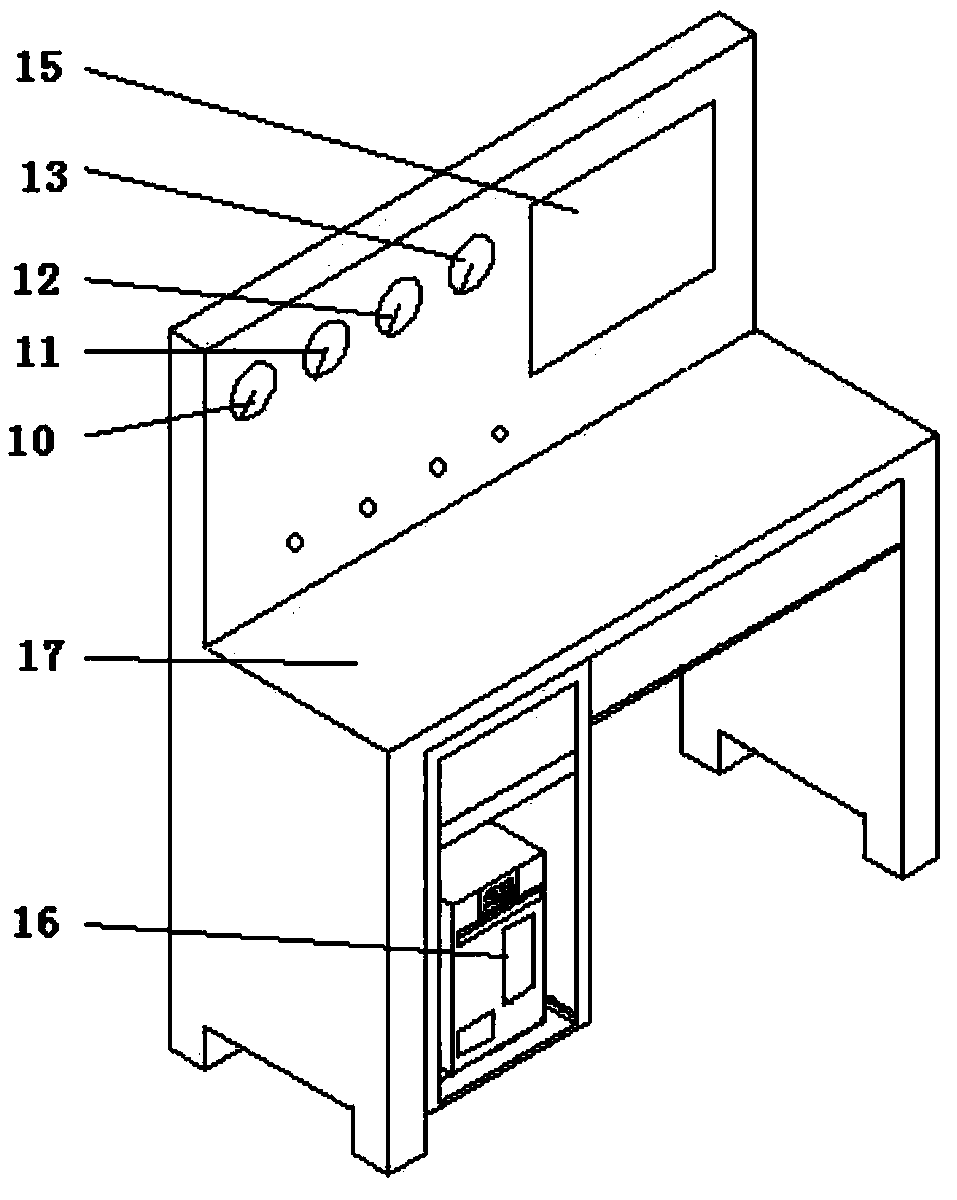

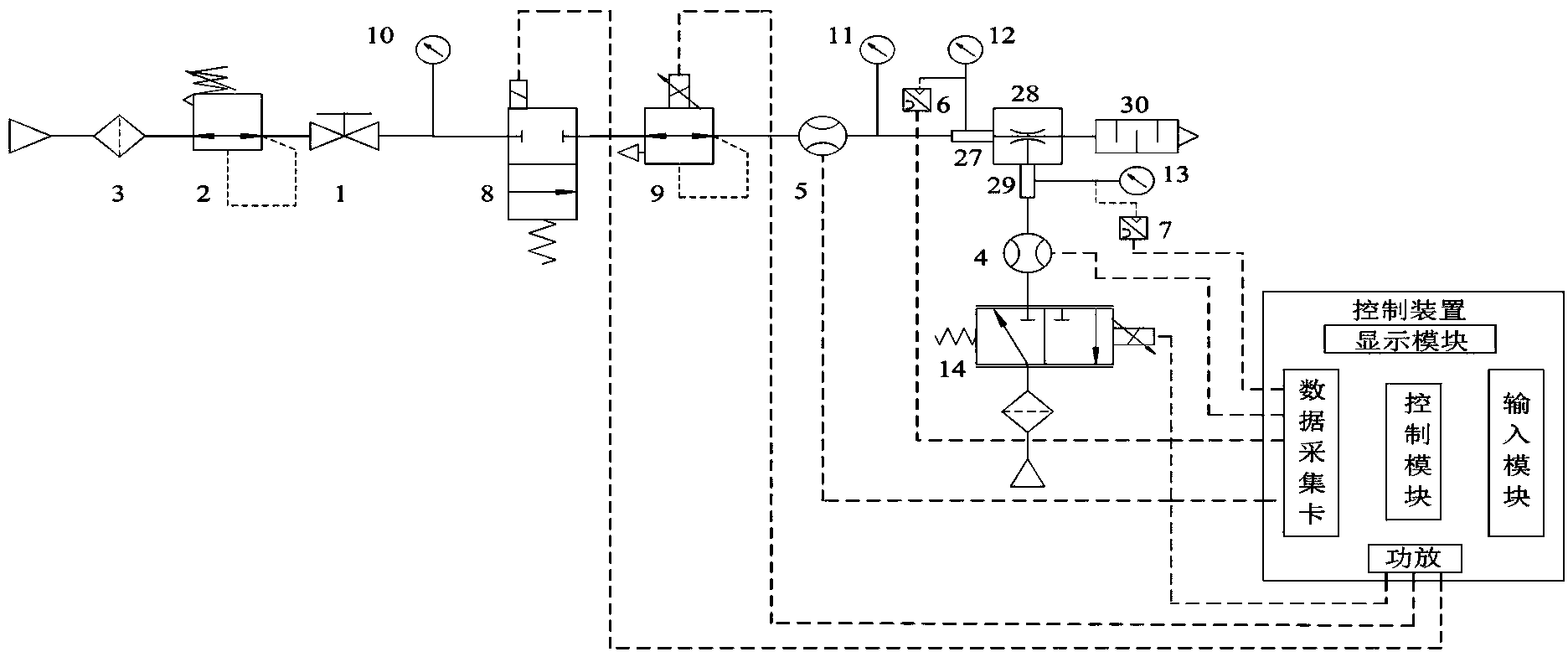

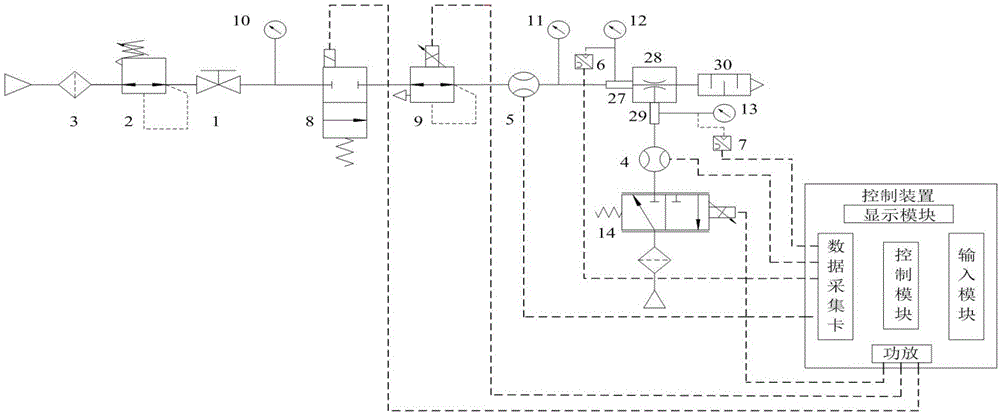

Vacuum generator performance detection equipment and detection method

ActiveCN104330278AScientific and reasonable detection dataGood repeatabilityStructural/machines measurementTesting equipmentEngineering

The invention discloses vacuum generator performance detection equipment which comprises a testing stand and an air source, wherein a flow stabilizer device, an air inlet flow control device, an air outlet flow control device, a pressure testing device and a vacuum testing unit are arranged on the testing stand; an inlet of the flow stabilizer device is connected with an air source; the flow stabilizer device is provided with two paths of outlets, wherein one path of outlet is connected with the air inlet flow control device, and the other path of outlet is connected with the pressure testing device; the vacuum testing unit is connected between the air inlet flow control device and the air outlet flow control device, and the air inlet flow control device is connected with the pressure testing device; the vacuum testing unit comprises a vacuum generator; a control terminal is arranged on the testing stand, and connected with the air inlet flow control device, the air outlet flow control device and the pressure testing device. A vacuum generator performance detection method is simple to operate; by adopting the vacuum generator performance detection method, the detection on vacuum degree, air consumption, maximal suction flow and vacuum degree-suction flow characteristics of the vacuum generator can be realized.

Owner:国家气动产品质量监督检验中心

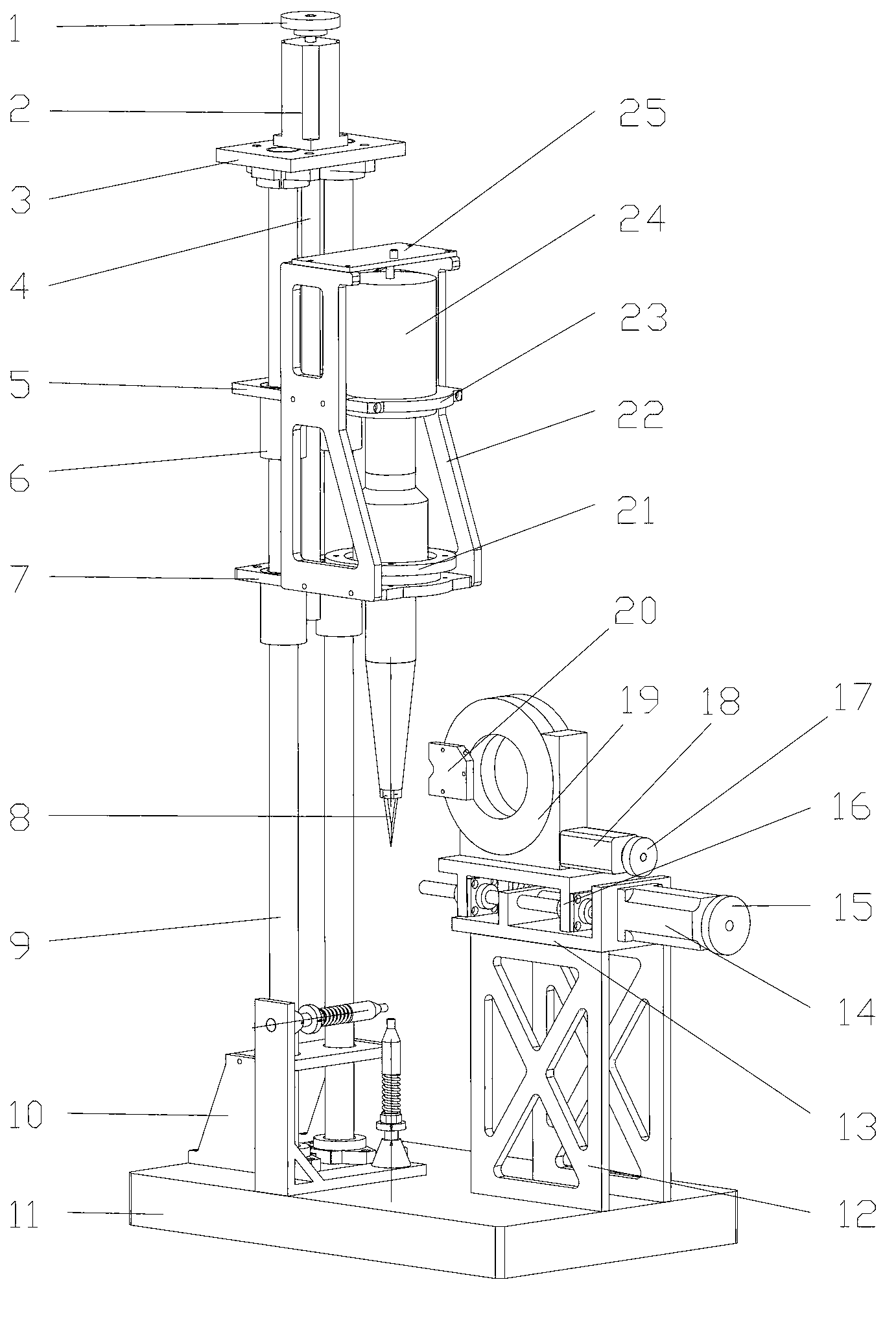

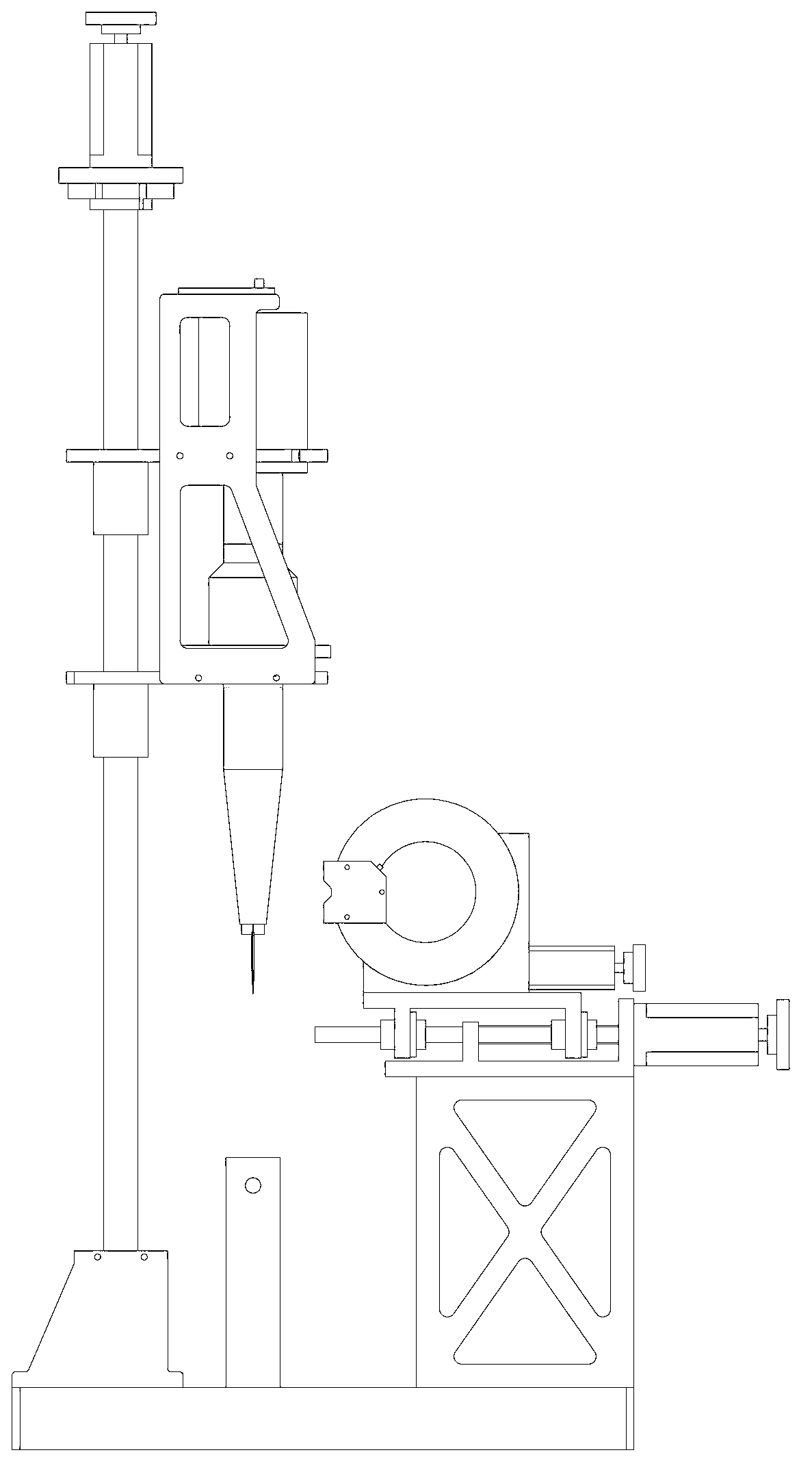

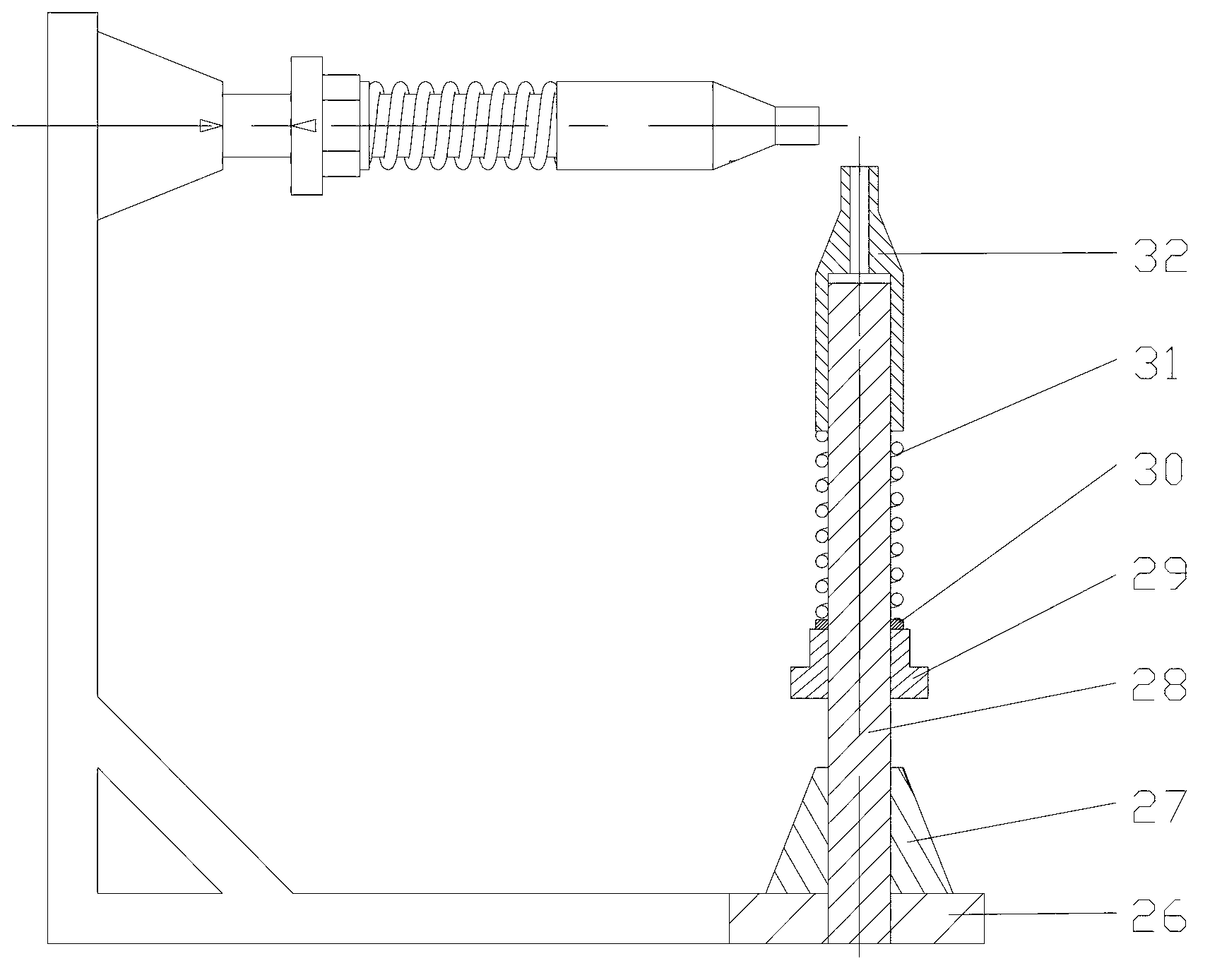

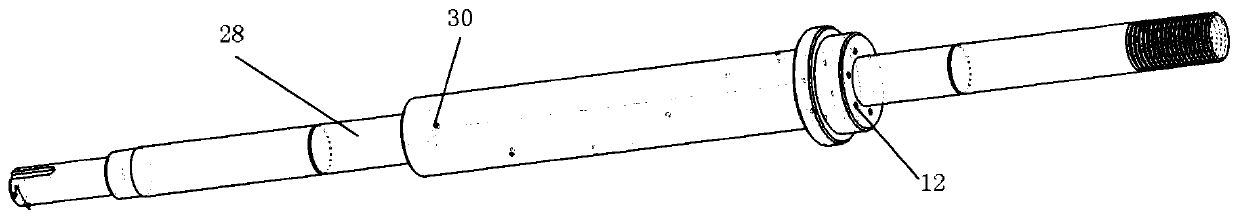

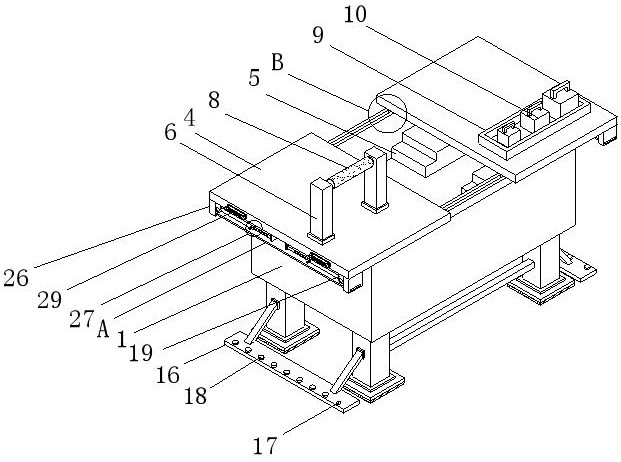

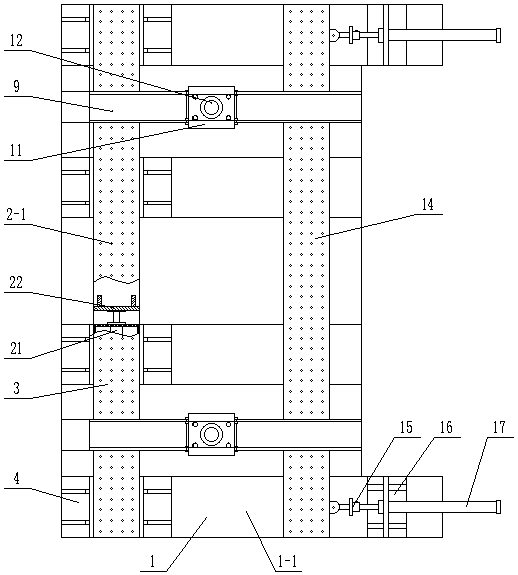

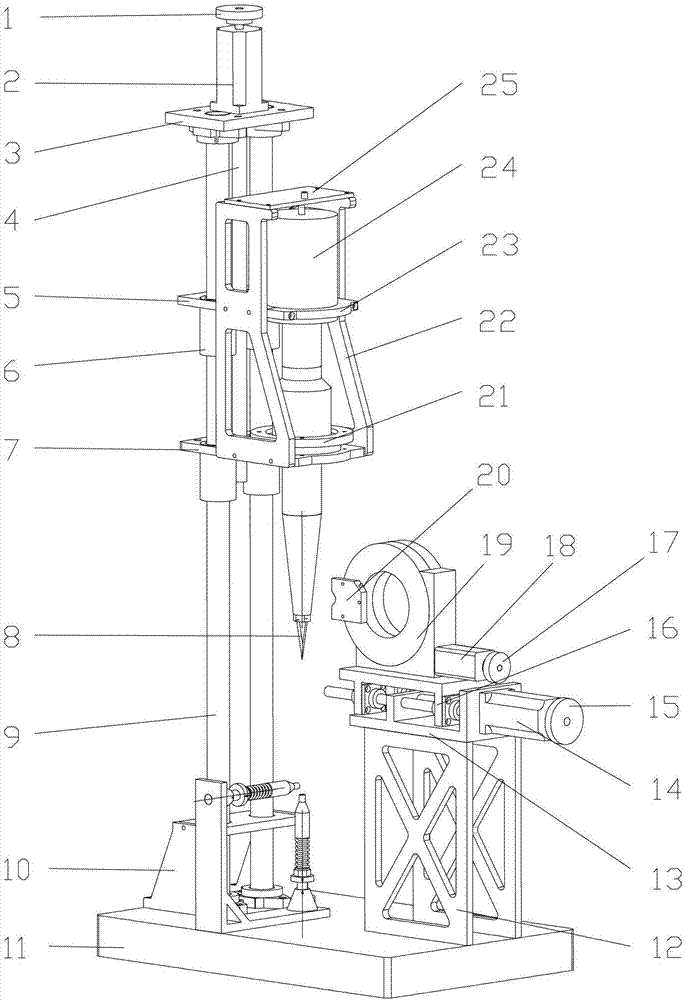

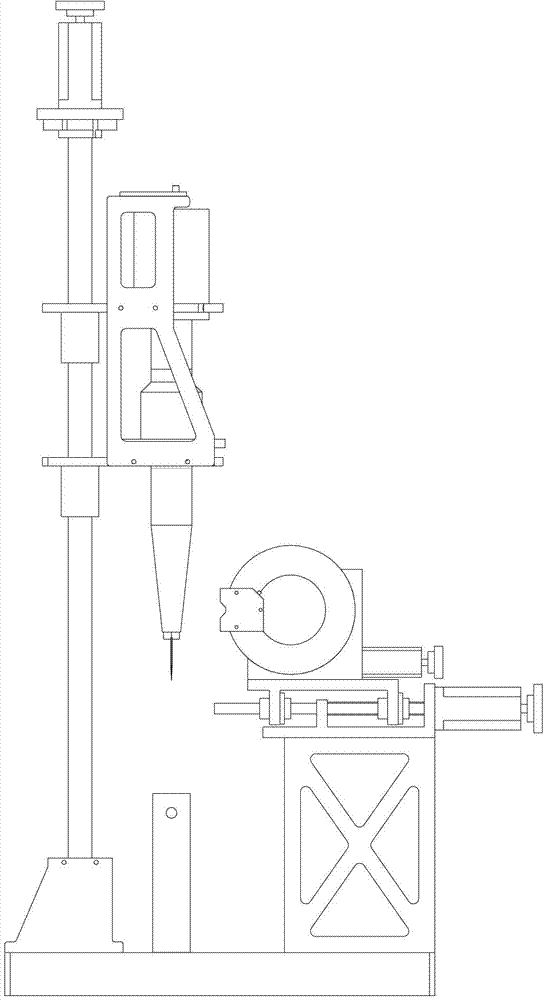

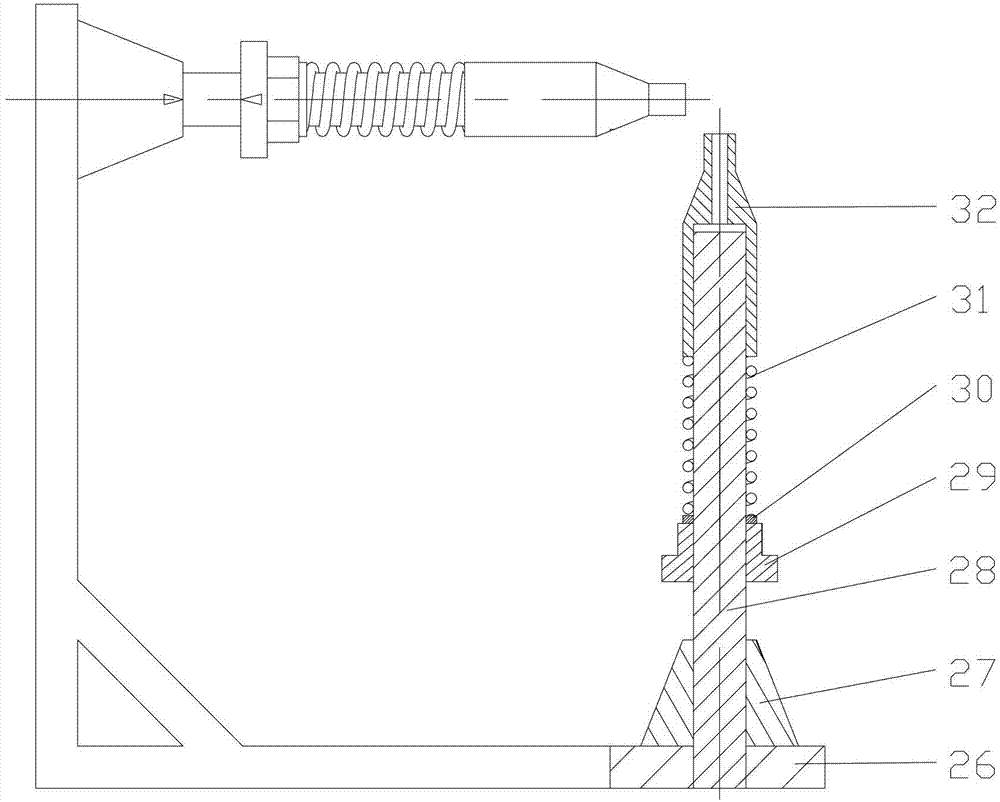

Overall performance testing rack of numerical control ultrasonic cutting sound main shaft

InactiveCN103323223AImprove performanceImprove performance testing resultsMachine part testingNumerical controlCombined test

The invention discloses an overall performance testing rack of a numerical control ultrasonic cutting sound main shaft. The overall performance testing rack comprises a base. Perpendicular linear guide rails, an artificial load device and a radial movement base are installed on the base. The perpendicular linear guide rails are in sliding fit with the ultrasonic cutting sound main shaft. The artificial load device is provided with two force application rods. The two force application rods are located at the axial position and the radial position of a cutting tool nose of the ultrasonic cutting sound main shaft respectively and used for applying artificial loads to the cutting tool nose. The radial movement base is provided with a testing probe which can move towards the ultrasonic cutting sound main shaft in a radial mode and rotate. According to the overall performance testing rack of the numerical control ultrasonic cutting sound main shaft, the testing site and various costs can be reduced, the measurement on different parameters under the same installation condition is provided, the testing errors under different installation conditions are reduced, the testing effect and the testing efficiency on the performance of the ultrasonic cutting sound main shaft are improved, and test bases are provided for the further perfection and the further improvement of the performance of the ultrasonic cutting sound main shaft.

Owner:HANGZHOU DIANZI UNIV

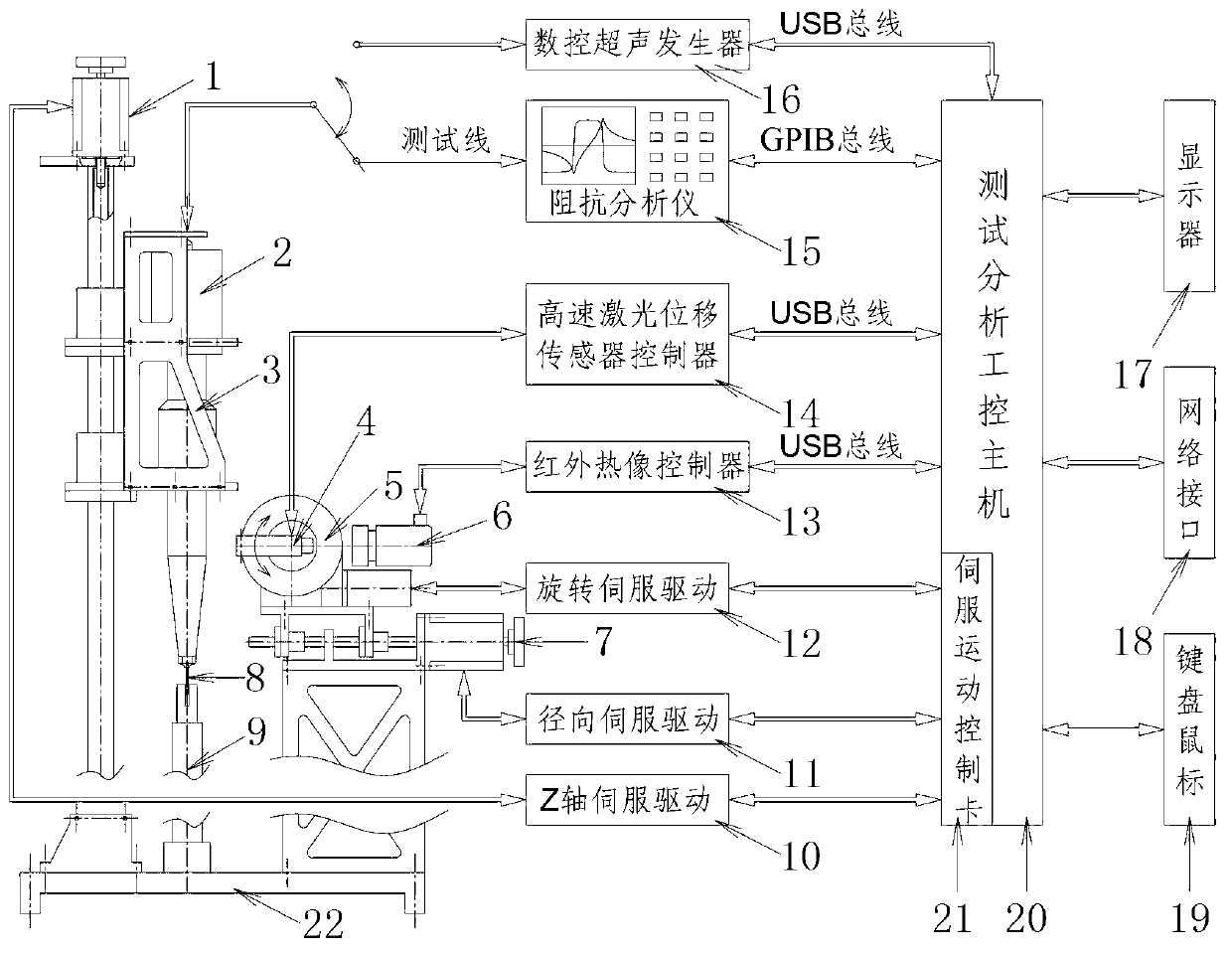

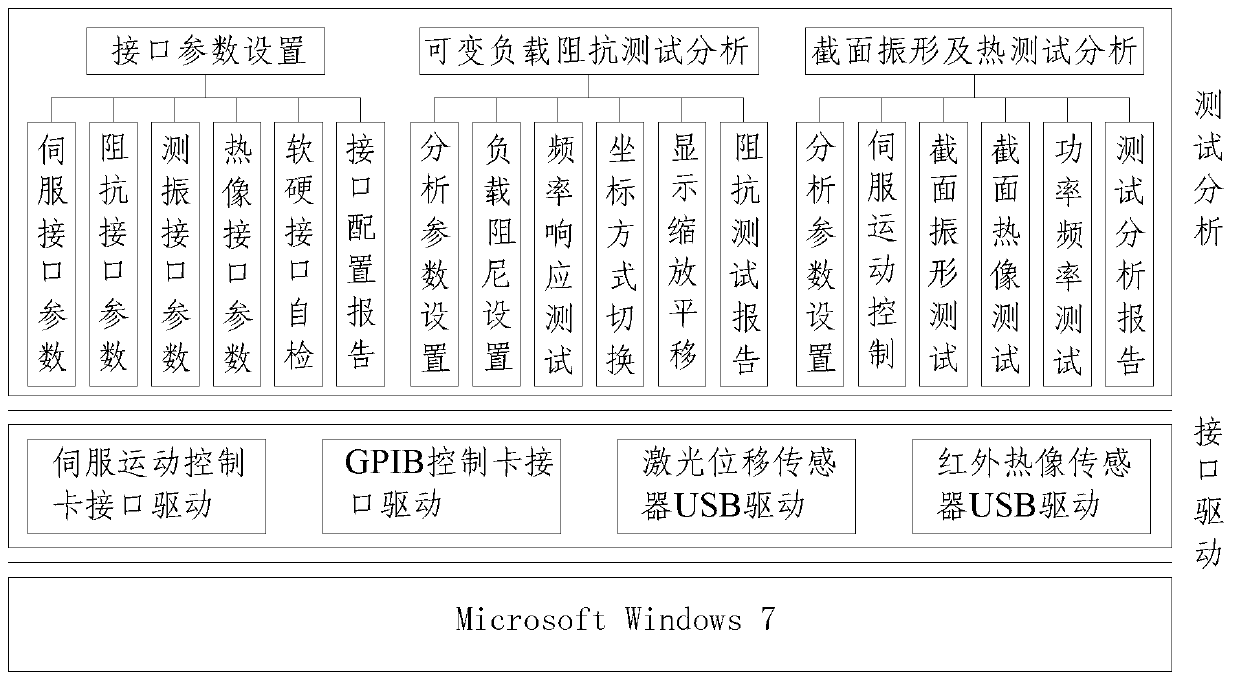

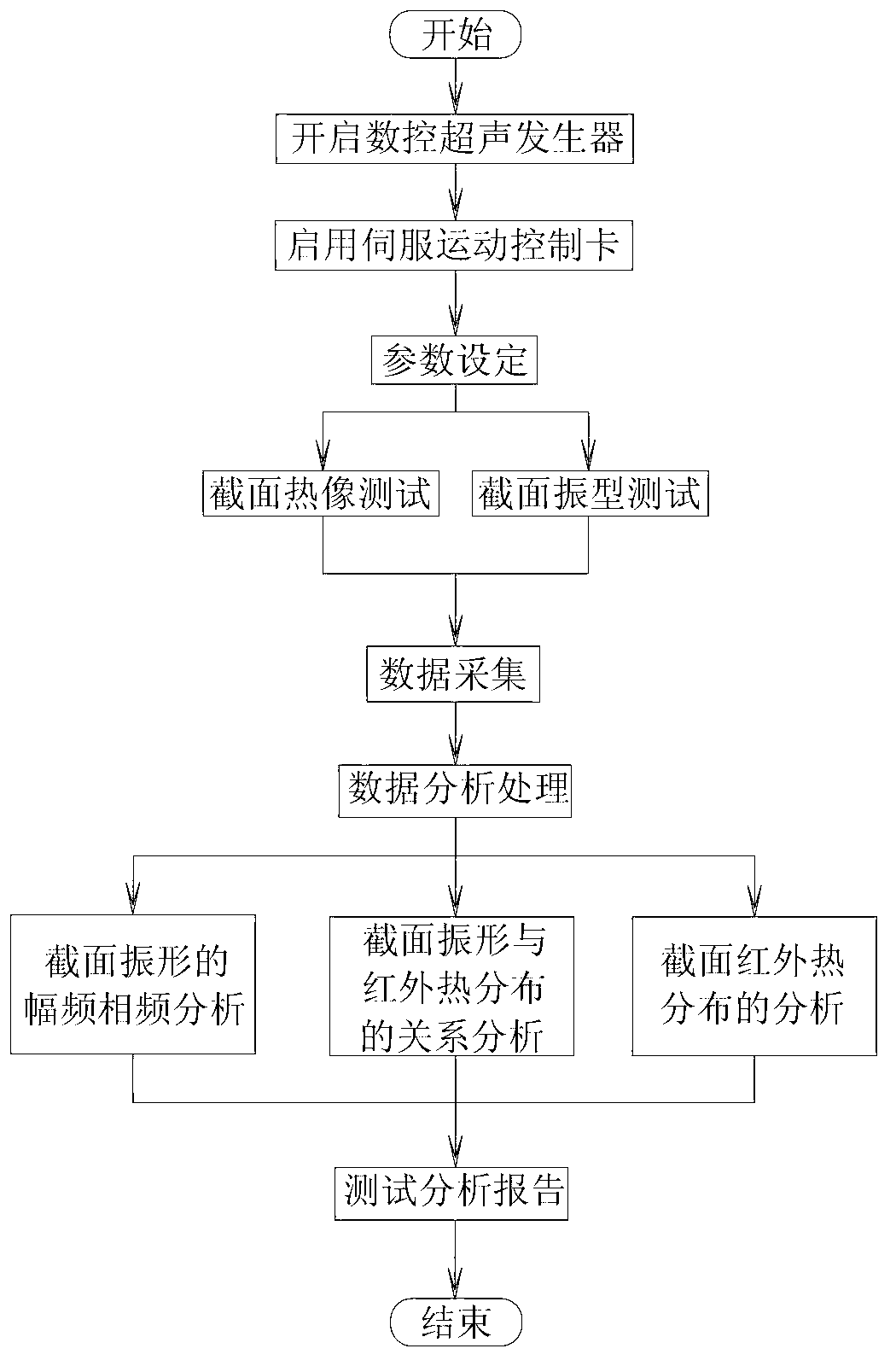

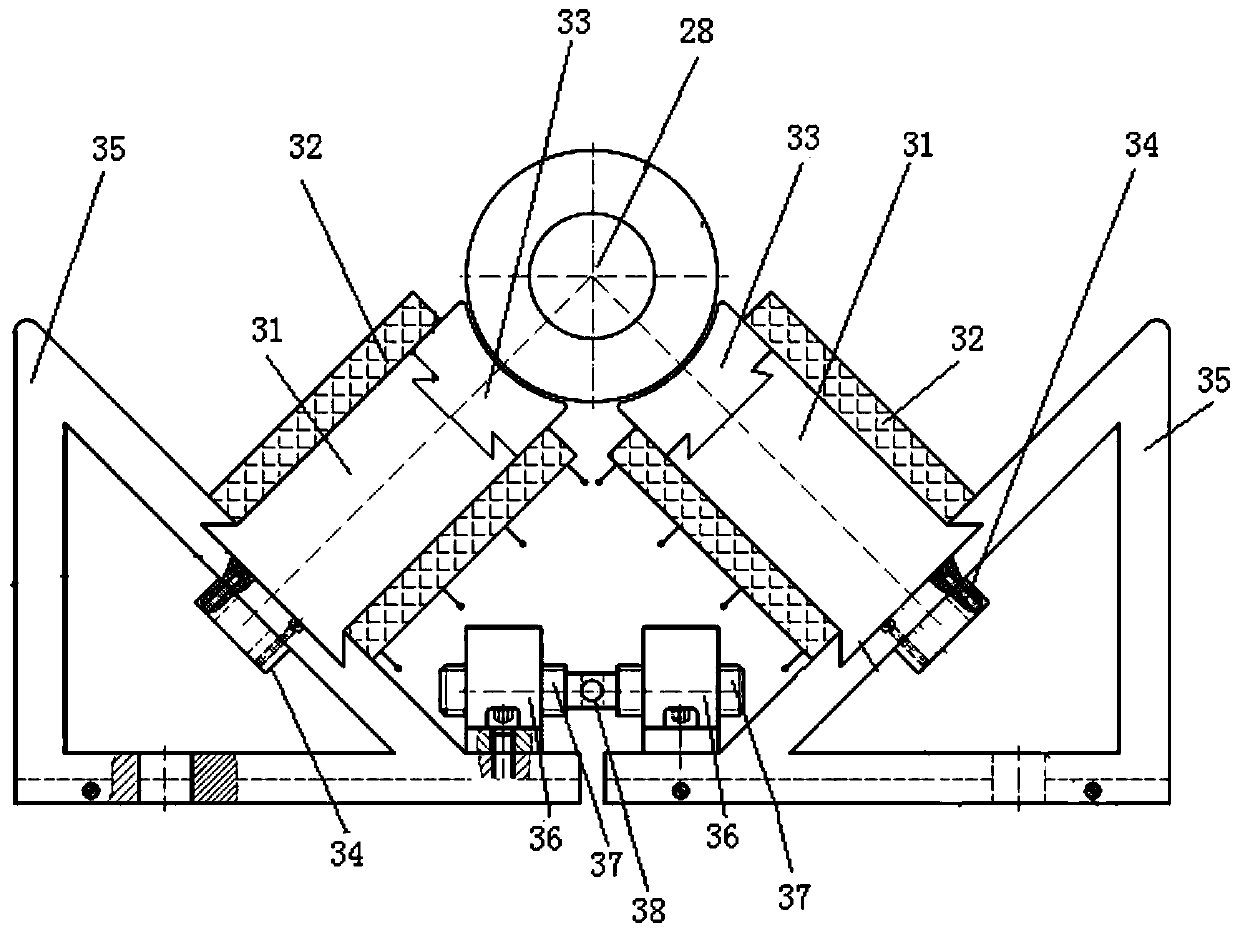

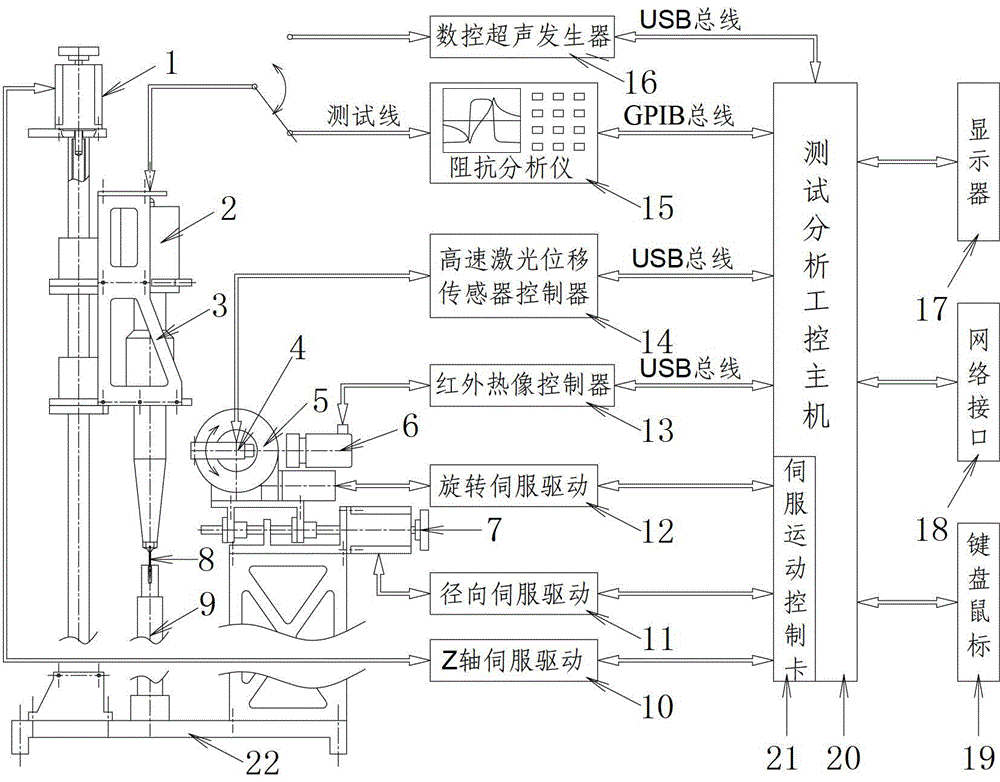

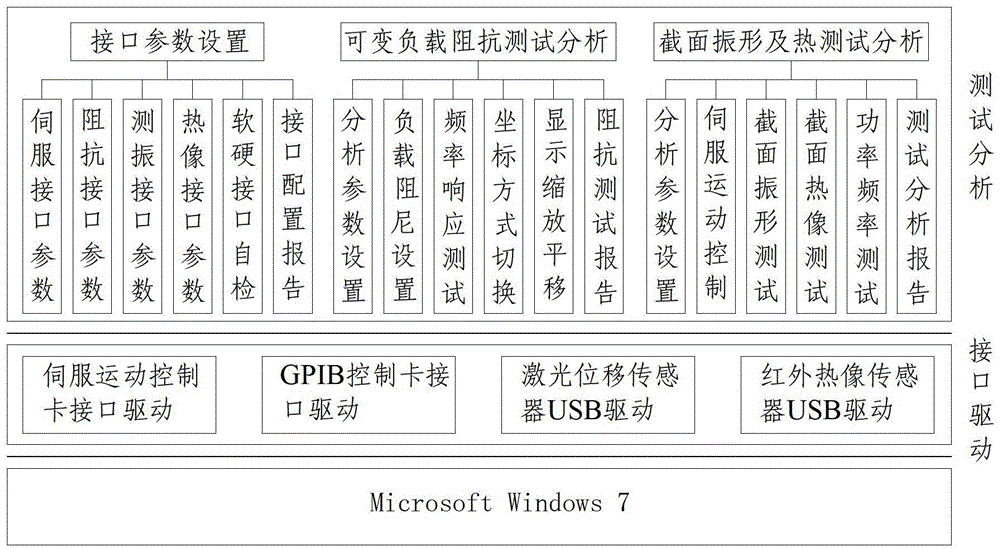

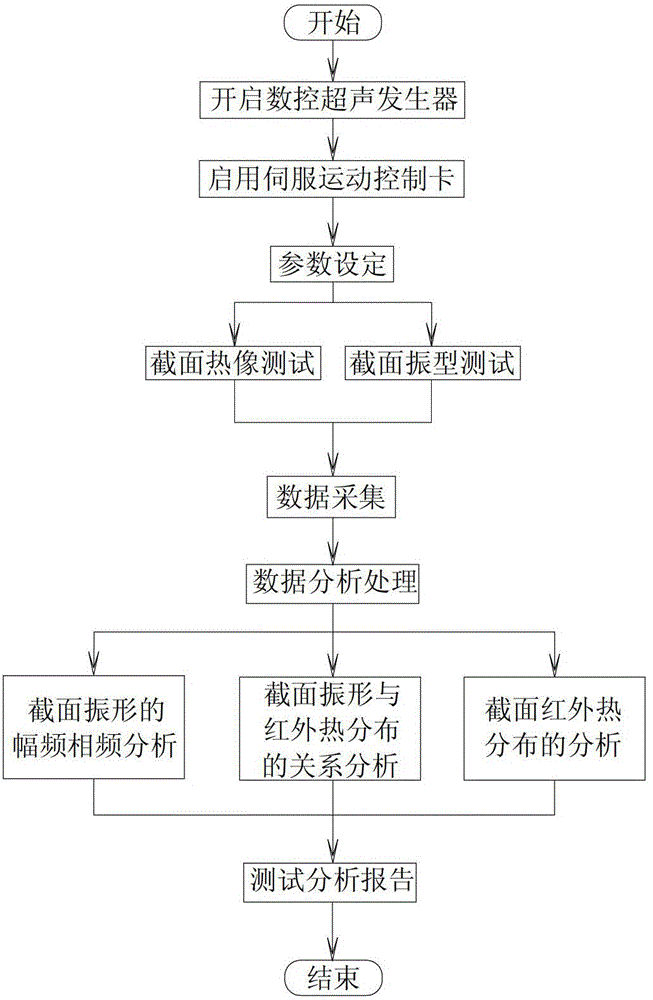

Ultrasonic cutting sound spindle comprehensive performance test analysis system

InactiveCN103344419AReduce the influence of human random factorsImprove stabilityMachine part testingNumerical controlTest analysis

The invention discloses an ultrasonic cutting sound spindle comprehensive performance test analysis system which comprises a vertical servo motor, an ultrasonic cutting sound spindle, a rotating servo rotary platform, a radial servo sliding platform, a variable damper and a test analysis industrial control host. A cutting tool is installed on the ultrasonic cutting sound spindle, an infrared thermography probe is fixed on the radial servo sliding platform, the infrared thermography probe is connected with the industrial control host through an infrared thermography controller, a laser displacement probe is installed on the rotating servo rotary platform, and the laser displacement probe is connected with the test analysis industrial control host through a controller of a high-speed laser displacement sensor. The ultrasonic cutting sound spindle is connected with a numerical control ultrasonic generator and an impedance analyzer through a single-pole double-throw switch, and the numerical control ultrasonic generator and the impedance analyzer are both connected with the test analysis industrial control host. The vertical servo motor, the radial servo sliding platform and the rotating servo rotary platform are connected with a servo motion control card respectively through Z-shaft servo driving, radial servo driving and rotary servo driving, and the servo motion control card is arranged in the industrial control host.

Owner:HANGZHOU DIANZI UNIV

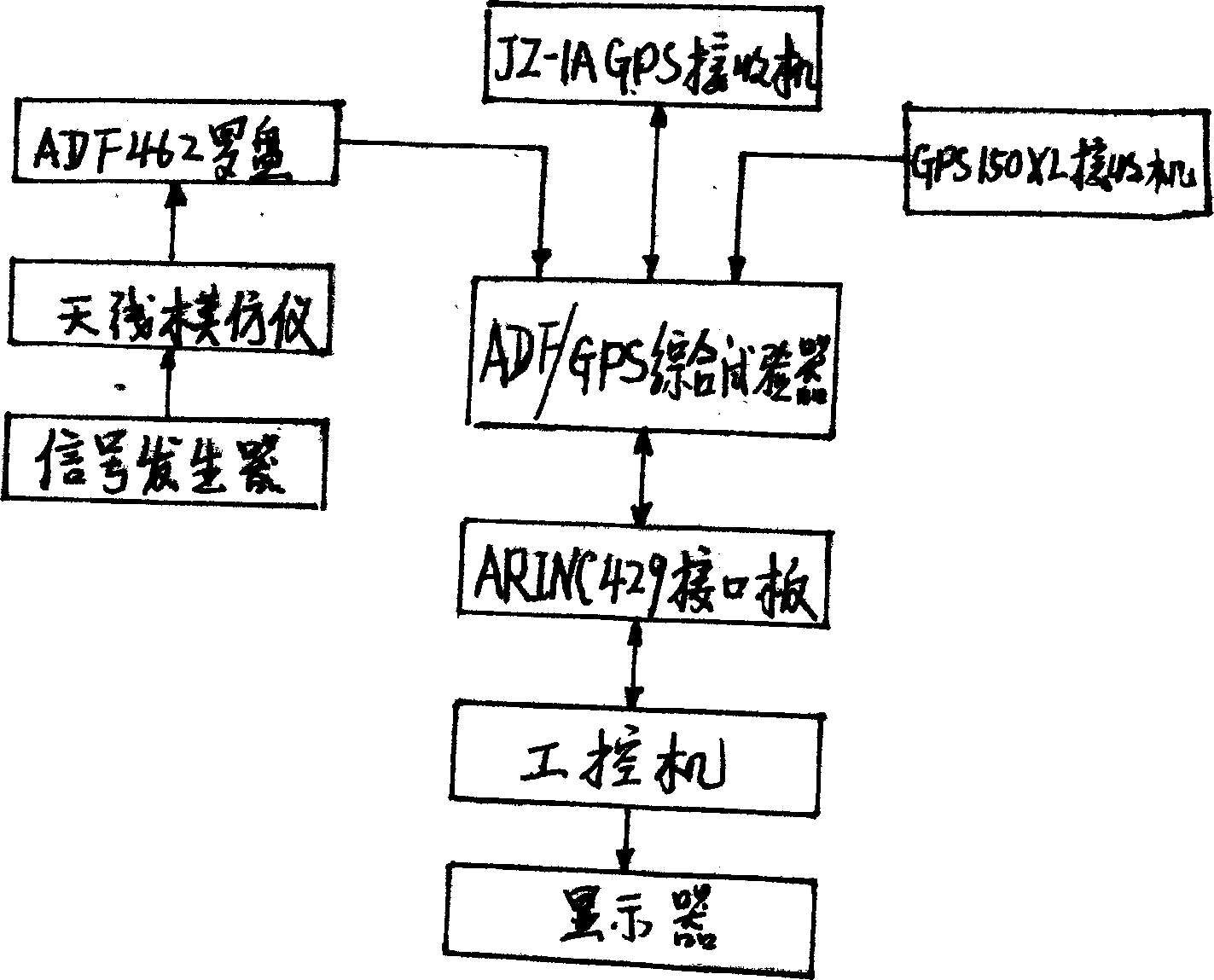

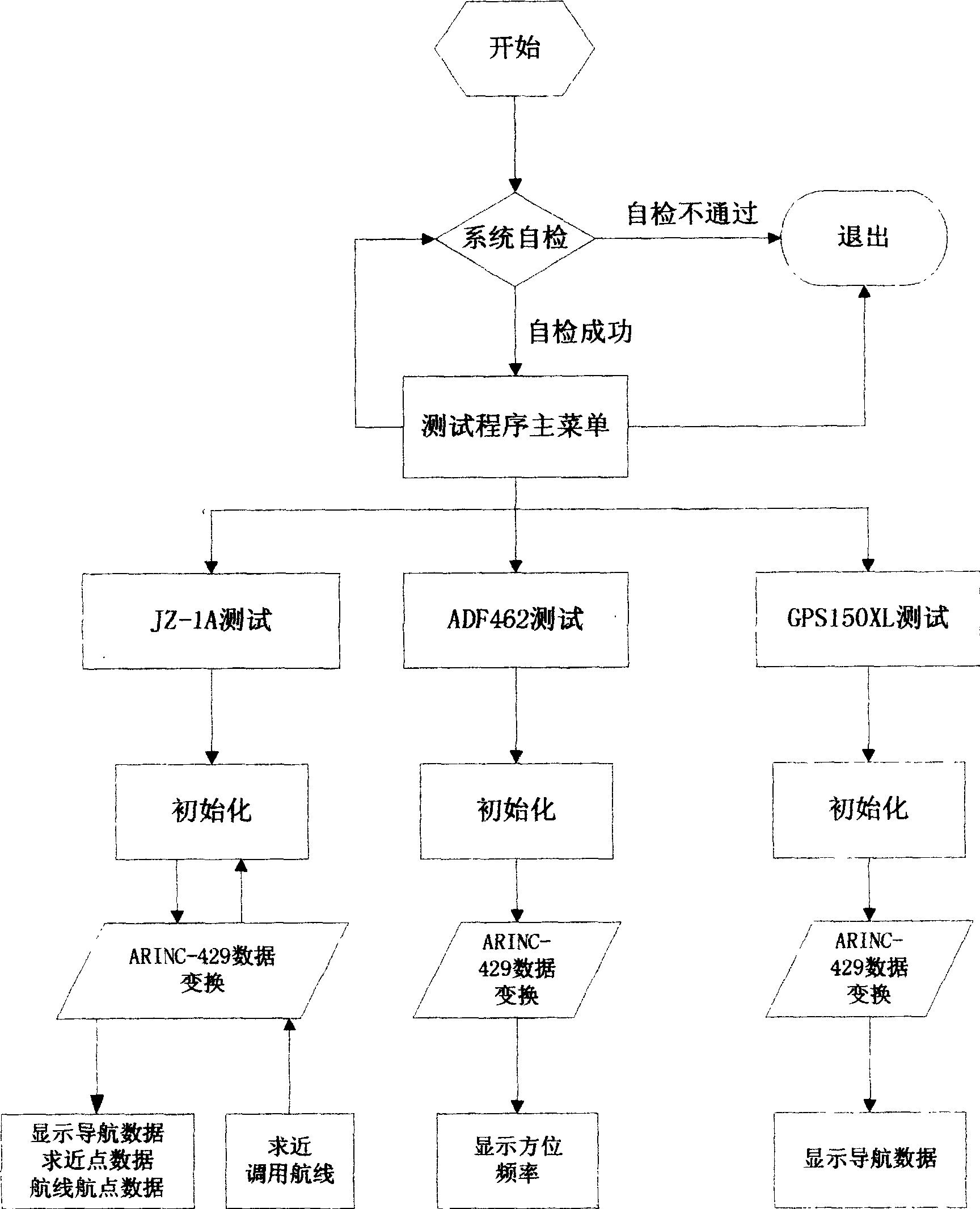

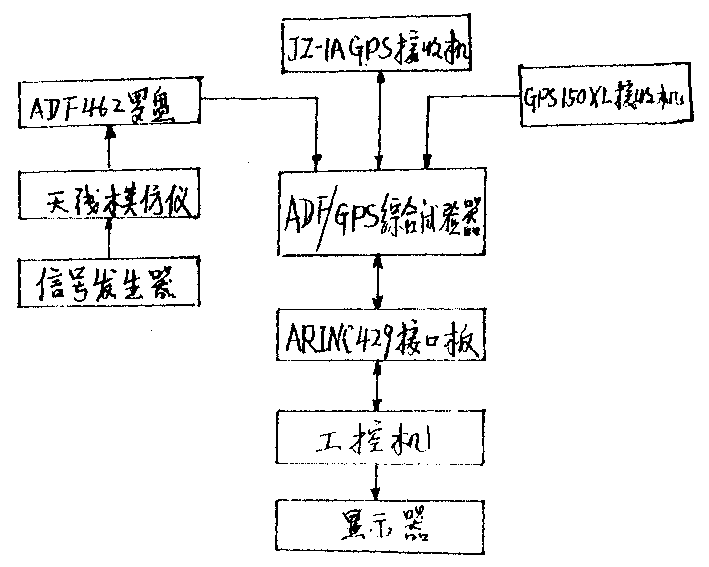

Automatic positioning system/global positioning system receiver comprehensive testing system

InactiveCN1456898AComprehensive performance testingReceivers monitoringElectrical testingCombined testGlobal positioning system receiver

A detection system is mainly composed of three parts with signal generator, system interface and computer detection, of which computer detection part is core of the detection system. The present invention can finalize collection and handling process of ADF data and GPS data as well as can make self-checking and period inspection for hardware of the detection system.

Owner:JIANGXI HONGDU AVIATION IND GRP

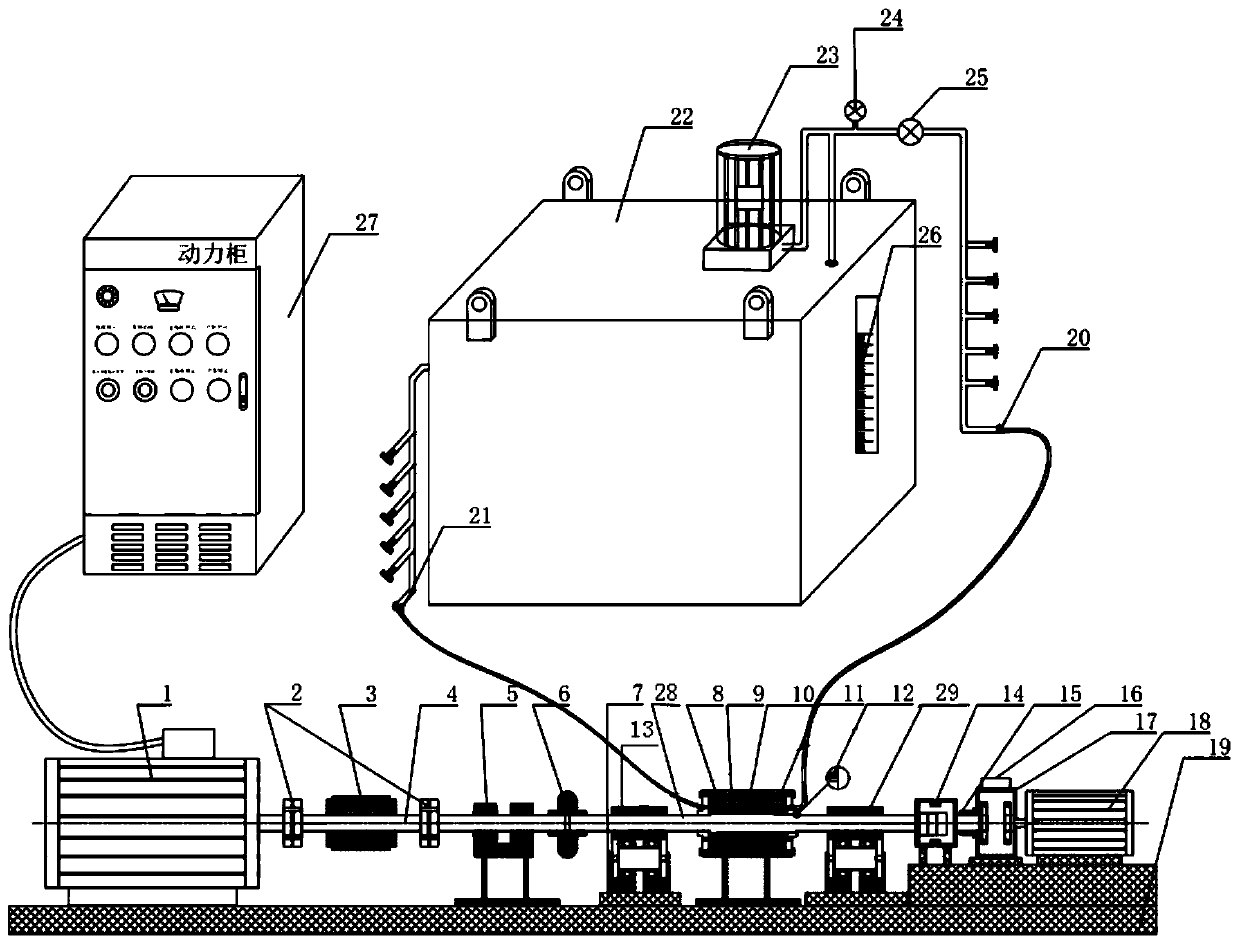

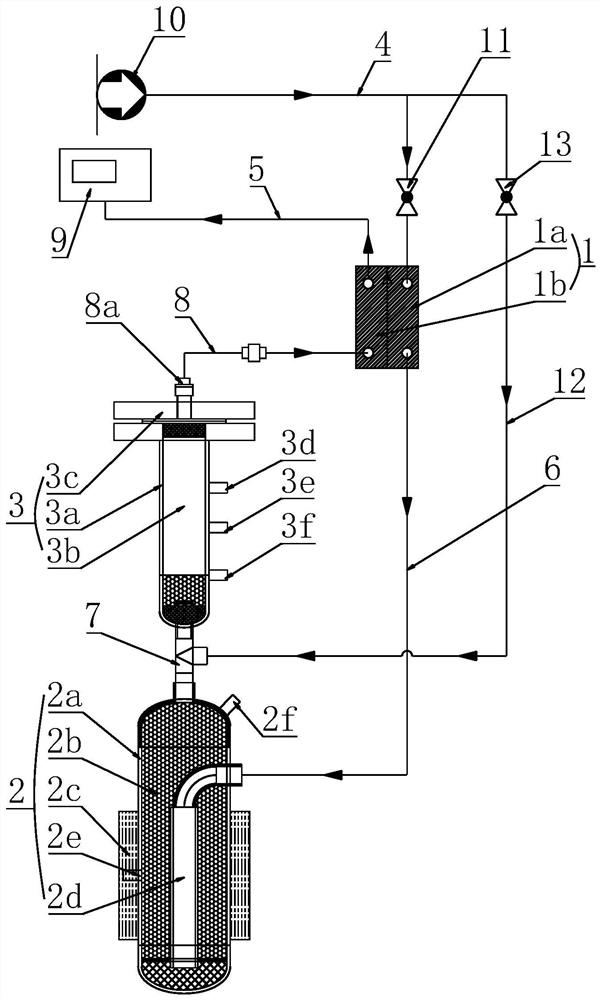

Water-lubricated bearing online monitoring test platform and bearing characteristic test analysis method

ActiveCN111272424AFeatures are easy to studyThe test content is richElectric signal transmission systemsMachine bearings testingRotational axisMotor speed

The invention discloses a water-lubricated bearing online monitoring test platform. The platform comprises a variable frequency motor, a torque tester, a rotating shaft, a main rotating shaft, a speedreducer, a permanent magnet generator and the like. The variable frequency motor is connected with an electric control cabinet, a rolling bearing support is arranged on the rotating shaft, and a bearing system support, a non-contact electromagnetic loading device a and a non-contact electromagnetic loading device b are arranged on the main rotating shaft. According to the present invention, different information fusion characteristics of multi-source parameters are considered, so that the characteristics of the water lubricated bearings can be researched more conveniently. The invention alsodiscloses a bearing characteristic test analysis method. The method comprises adjusting the water supply pressure, the variable frequency motor rotating speed and the shafting load; measuring variousparameters, analyzing the energy supply mechanism of an energy collection system of the rotating machinery wireless devices and the communication quality of the energy collection system of the rotating machinery wireless devices; and analyzing the bearing friction characteristics, the lubricating characteristics and the lubricating mechanism. According to the invention, various performance tests of the water-lubricated bearings are perfected, and test data and scientific basis are provided for the safe and stable operation of the bearings, the design and manufacture of the bearings and the like.

Owner:SHAANXI SCI TECH UNIV

Vacuum generator performance testing equipment and testing method

ActiveCN104330278BGood repeatabilityFlexible settingsStructural/machines measurementEngineeringInlet flow

The invention discloses vacuum generator performance detection equipment which comprises a testing stand and an air source, wherein a flow stabilizer device, an air inlet flow control device, an air outlet flow control device, a pressure testing device and a vacuum testing unit are arranged on the testing stand; an inlet of the flow stabilizer device is connected with an air source; the flow stabilizer device is provided with two paths of outlets, wherein one path of outlet is connected with the air inlet flow control device, and the other path of outlet is connected with the pressure testing device; the vacuum testing unit is connected between the air inlet flow control device and the air outlet flow control device, and the air inlet flow control device is connected with the pressure testing device; the vacuum testing unit comprises a vacuum generator; a control terminal is arranged on the testing stand, and connected with the air inlet flow control device, the air outlet flow control device and the pressure testing device. A vacuum generator performance detection method is simple to operate; by adopting the vacuum generator performance detection method, the detection on vacuum degree, air consumption, maximal suction flow and vacuum degree-suction flow characteristics of the vacuum generator can be realized.

Owner:国家气动产品质量监督检验中心

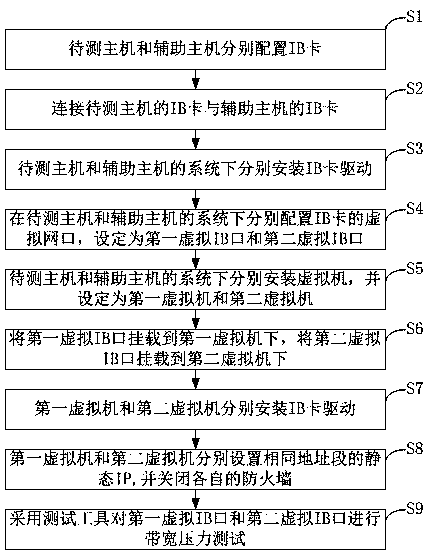

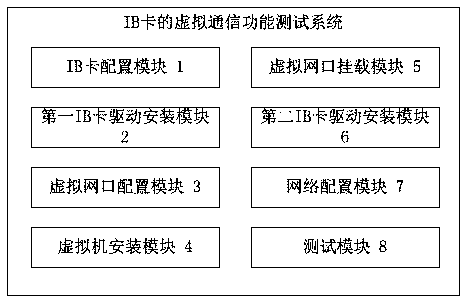

Virtual communication function test method and virtual communication function test system of IB card

InactiveCN109474500AComprehensive performance testingCheck CompatibilityData switching networksComputer hardwareVirtualization

The invention provides a virtual communication function test method and a virtual communication function test system of an IB card. The method comprises the following steps: constructing a test machine environment, and interconnecting to the IB card; creating a virtual IB port by each test machine; installing a virtual machine on each test machine; mounting the created virtual IB port to the installed virtual machine by each test machine, and allocating an IP address of the same address section for each virtual IB port; and testing a virtual communication function for different test machines through a test tool. The system comprises an IB card configuration module, a first IB card driver installation module, a virtual network port configuration module, a virtual machine installation module, a virtual network port mounting module, a second IB card driver installation module, a network configuration module and a test module. With the method and the system provided by the invention, testfor virtualized functions of the IB card and a direct communication function of the virtual network port is realized, test for network functions and performance of the IB card in server test is perfected, and compatibility of the server and the IB card is detected better.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

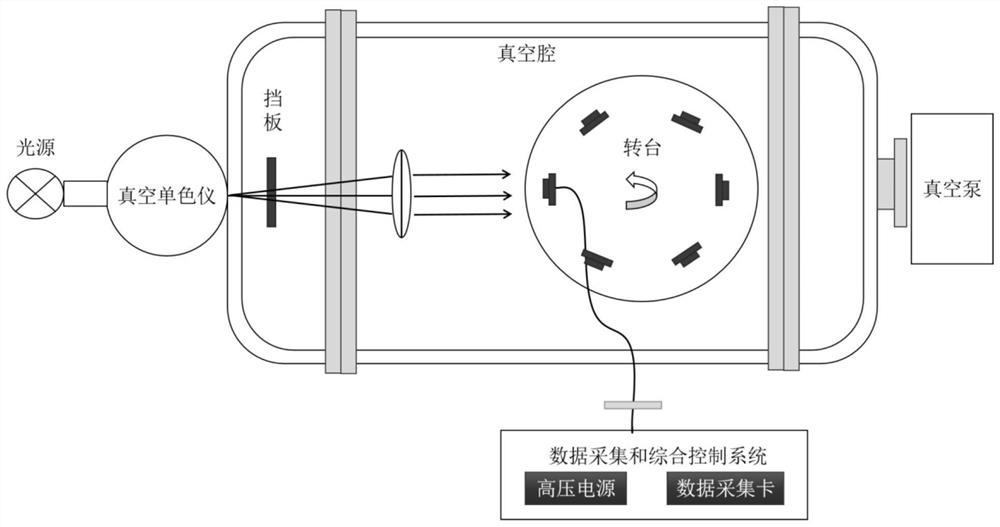

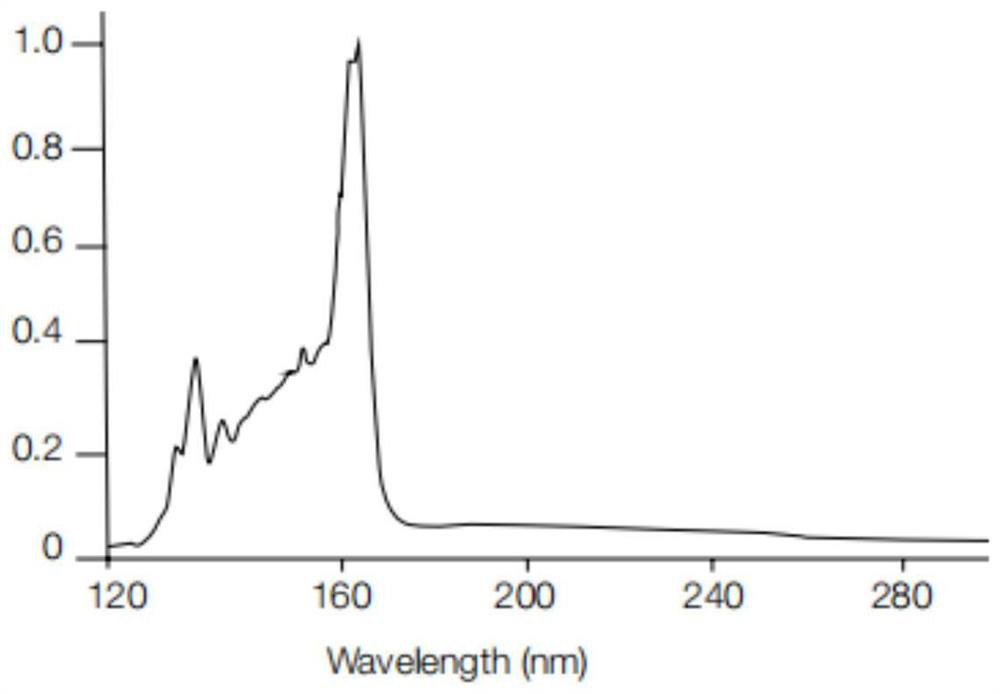

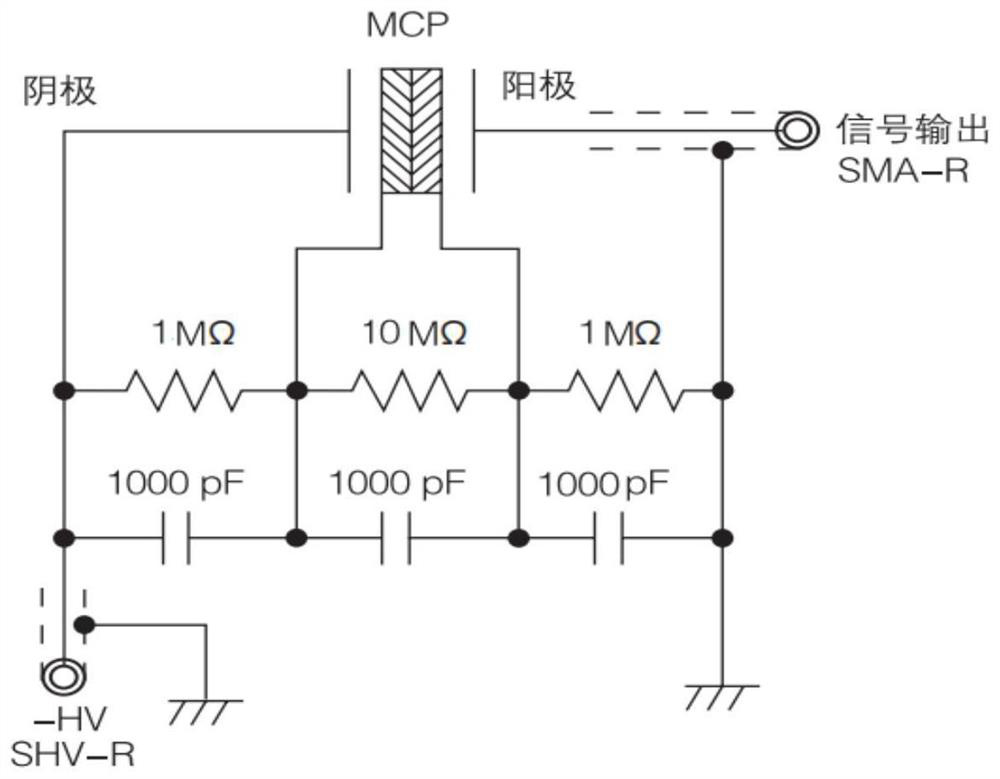

Vacuum ultraviolet photomultiplier testing device

PendingCN111856235AComprehensive performance testingTest accurateIndividual semiconductor device testingPhotovoltaic energy generationLight TestingSystem testing

The invention provides a vacuum ultraviolet photomultiplier testing device, which comprises a vacuum system, a testing clamp, a light source system, a data acquisition and control system and a computer system, wherein the vacuum system provides vacuum degree requirements for testing, a vacuum ultraviolet photomultiplier is arranged in the testing clamp and is integrally arranged in a vacuum cavity, the light source system is used for providing a test light source of the vacuum ultraviolet photomultiplier, generating an ultraviolet light source and irradiating the ultraviolet light source to the cathode surface of the ultraviolet photomultiplier positioned in the vacuum cavity, and the data acquisition and control system is used for controlling test parameters and test configuration of thesystem, reading a system test data value, transmitting the system test data value to the computer system and analyzing and processing data. Through relative testing, dark current, cathode radiation sensitivity, quantum efficiency, anode radiation sensitivity and gain parameters of a vacuum ultraviolet photomultiplier are tested, and a performance testing and evaluating system of the vacuum ultraviolet photomultiplier is perfected.

Owner:NORTH NIGHT VISION TECH

Catalyst performance evaluation device

PendingCN111830191AImprove versatilityFlexible adjustmentChemical analysis using catalysisThermometers using electric/magnetic elementsPtru catalystProcess engineering

The invention discloses a catalyst performance evaluation device. The device comprises a heat exchanger, a heater and a reactor, wherein the heat exchanger has a preheating side and a heat recovery side, the preheating side is connected with an air inlet pipe, the heat recovery side is connected with an air outlet pipe, a first pipeline is connected between the preheating side and the heater, a second pipeline is connected between the heater and the reactor, a third pipeline is connected between the reactor and the heat recovery side, the reactor comprises a cylinder body, a catalyst bin is arranged in the cylinder body and used for containing a catalyst, and a flange plate cylinder cover is detachably arranged at an upper end of the cylinder body. The device is advantaged in that universality is good, performance of various catalysts can be evaluated, the interval time for replacing the catalysts is short, heating energy consumption is low, working efficiency is high, and economic performance is good.

Owner:CHONGQING BAOSI FLAMMABLE GAS ENG CO LTD

Multifunctional robot joint performance testing device

InactiveCN112179637AIncrease frictionComprehensive performance testingMachine part testingBody jointsSimulation

The invention relates to the technical field of robot testing equipment, and discloses a multifunctional robot joint performance testing device which comprises a testing box body. Two sliding groovesare formed in the top end of the testing box body, and connecting inserting blocks are inserted into the two sliding grooves. The top end of the connecting inserting block is fixedly connected with atesting platform, and the inner bottom wall of the testing box body is fixedly connected with a step block. The device has the following advantages and effects that when the device is used and when ajoint of an upper part of the robot needs to be tested, the robot can be controlled to clamp the pull rod to enable the robot to do pull-up motion to detect the connection stability of an upper body joint of the robot, and the rubber sleeve can increase the friction force between the robot and the pull rod, so that the robot lifts a weight in the weight groove block, the stability of connection atthe arm joints of the robot can be detected, the test platform is pulled, and the test platform can move in the sliding groove through the connecting insertion block.

Owner:孙国花

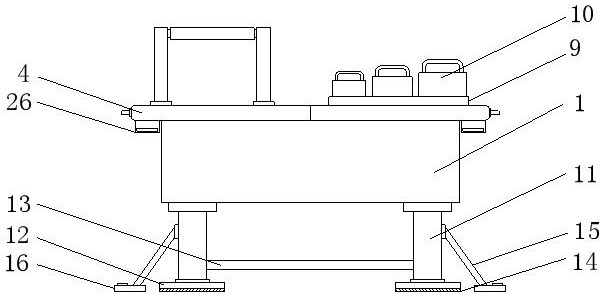

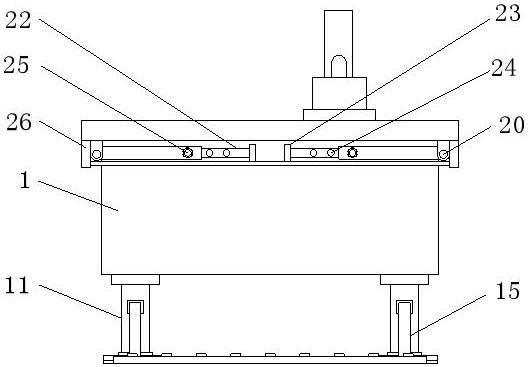

Microcomputer servo control bridge expansion joint performance tester

PendingCN109459380AAchieve accuracyRealize visualizationMaterial strength using tensile/compressive forcesUsing mechanical meansMicrocomputerExpansion joint

The invention discloses a microcomputer servo control bridge expansion joint performance tester which comprises a base, a first moving beam and a second moving beam; the first moving beam and the second moving beam are arranged on the base; a first drive device used for driving the first moving beam to move in a width direction of the base is arranged between the first moving beam and the base; asecond drive device used for driving the second moving beam to move in a length direction of the base and a third drive device used for driving the second moving beam to move in the length direction of the base are arranged between the second moving beam and the base; and the upper side of each of the first moving beam and the second moving beam is provided with a friction tester and a pressure tester. The microcomputer servo control bridge expansion joint performance tester provided by the invention can perform comprehensive performance detection on the bridge expansion joint performance, isconvenient to operate and can ensure the accuracy of detection data of the bridge expansion joint performance.

Owner:SHANDONG LUDA TEST INSTR

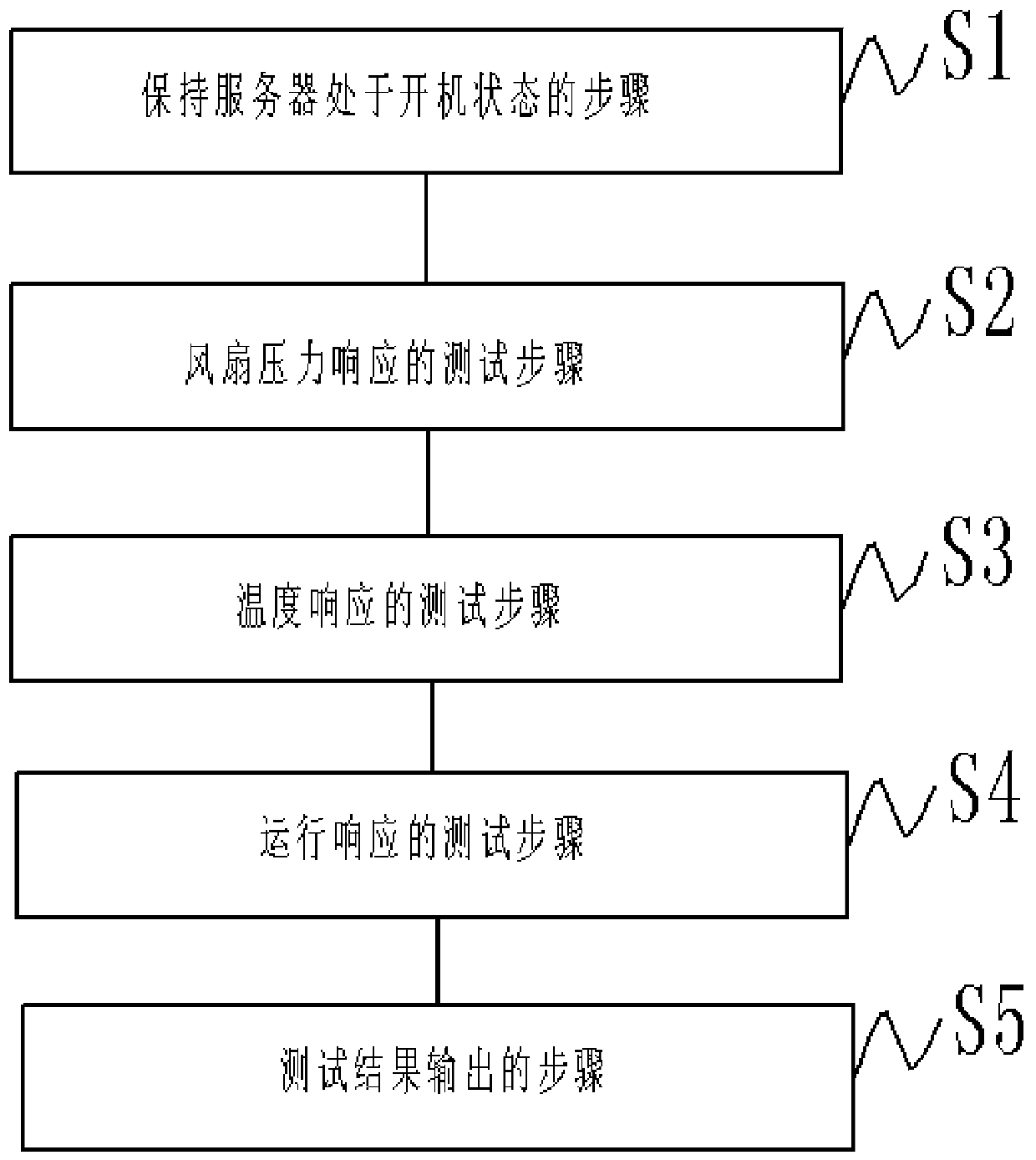

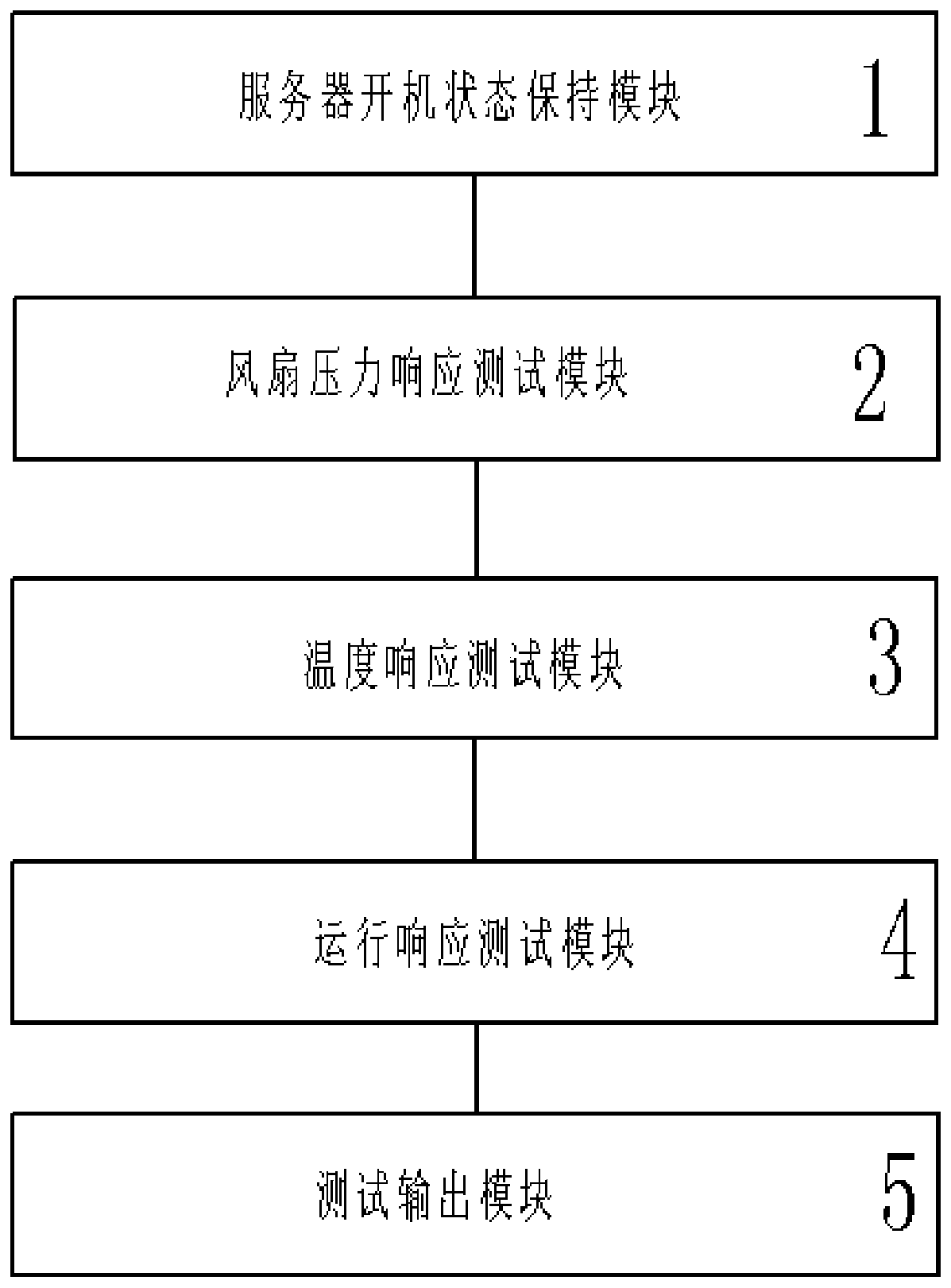

Testing method and system for monitoring running state of server fan

ActiveCN110886716ASee healthComprehensive performance testingDigital data processing detailsPump controlEmbedded systemServer

The invention relates to a testing method and system for monitoring the running state of a server fan. The method comprises the following steps that S1, a server is kept in a startup state; S2, a fanpressure response is tested; S3, a temperature response is tested; S4, a running response is tested; and S5, a testing result is output.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

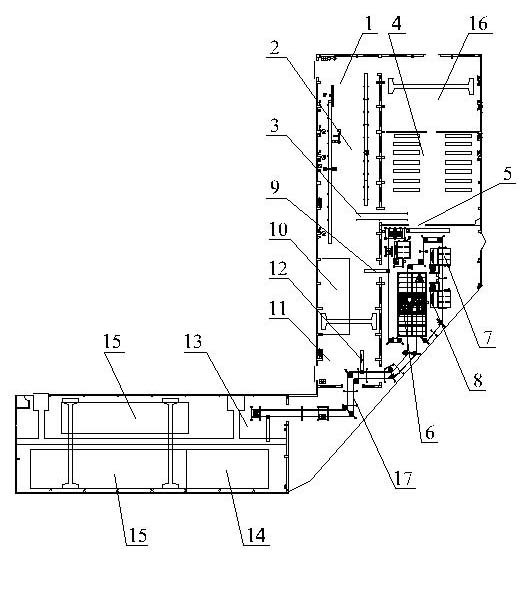

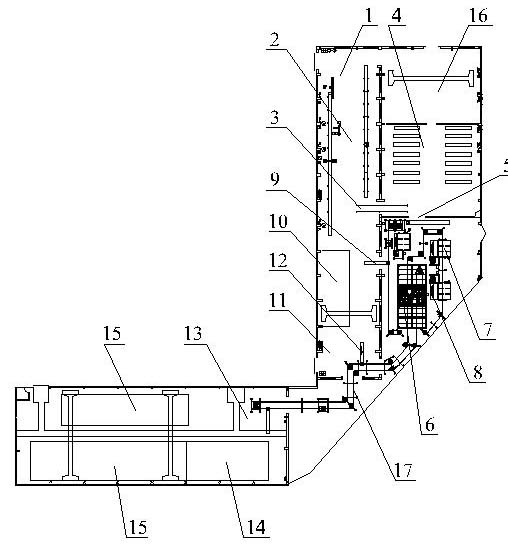

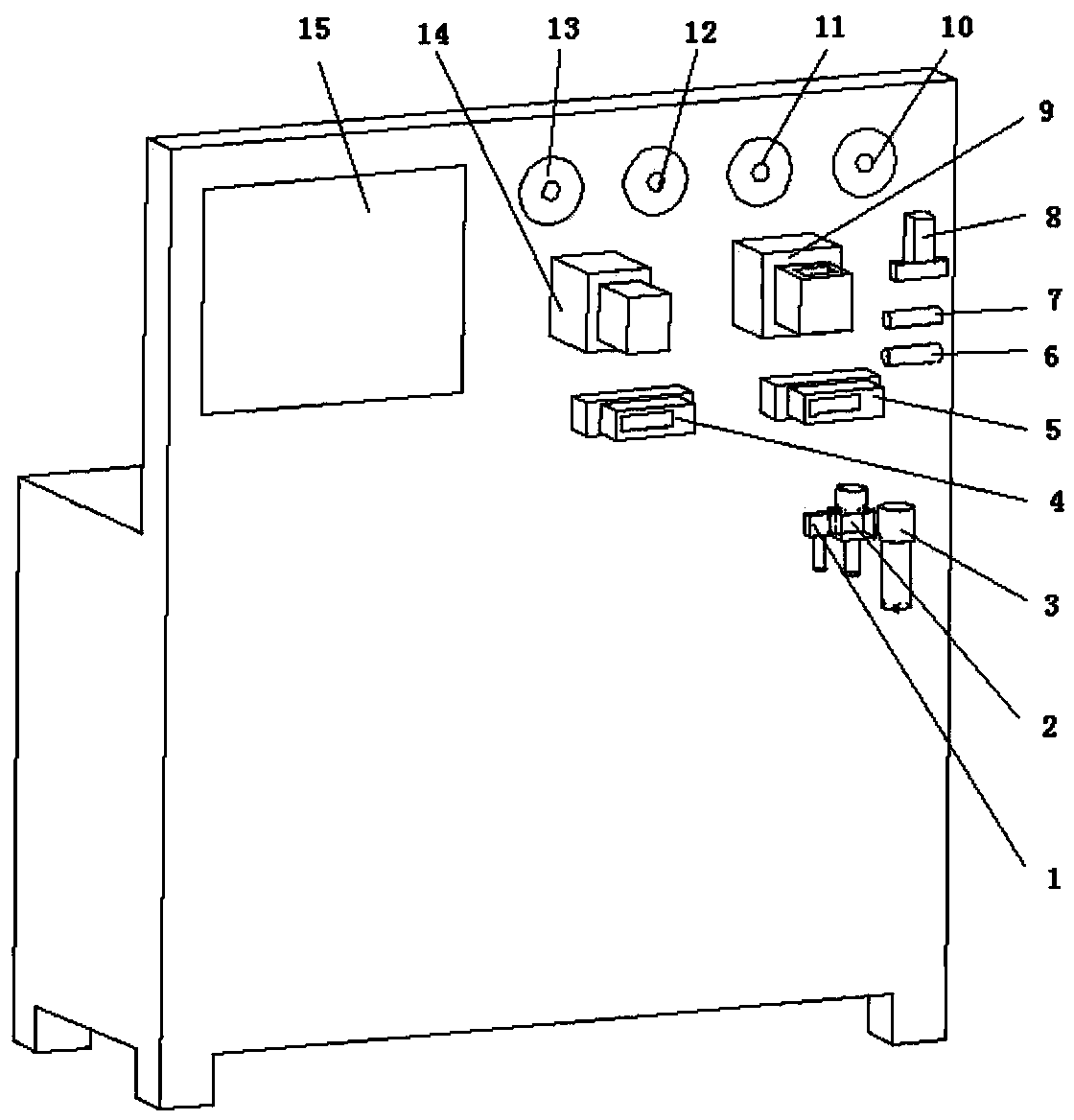

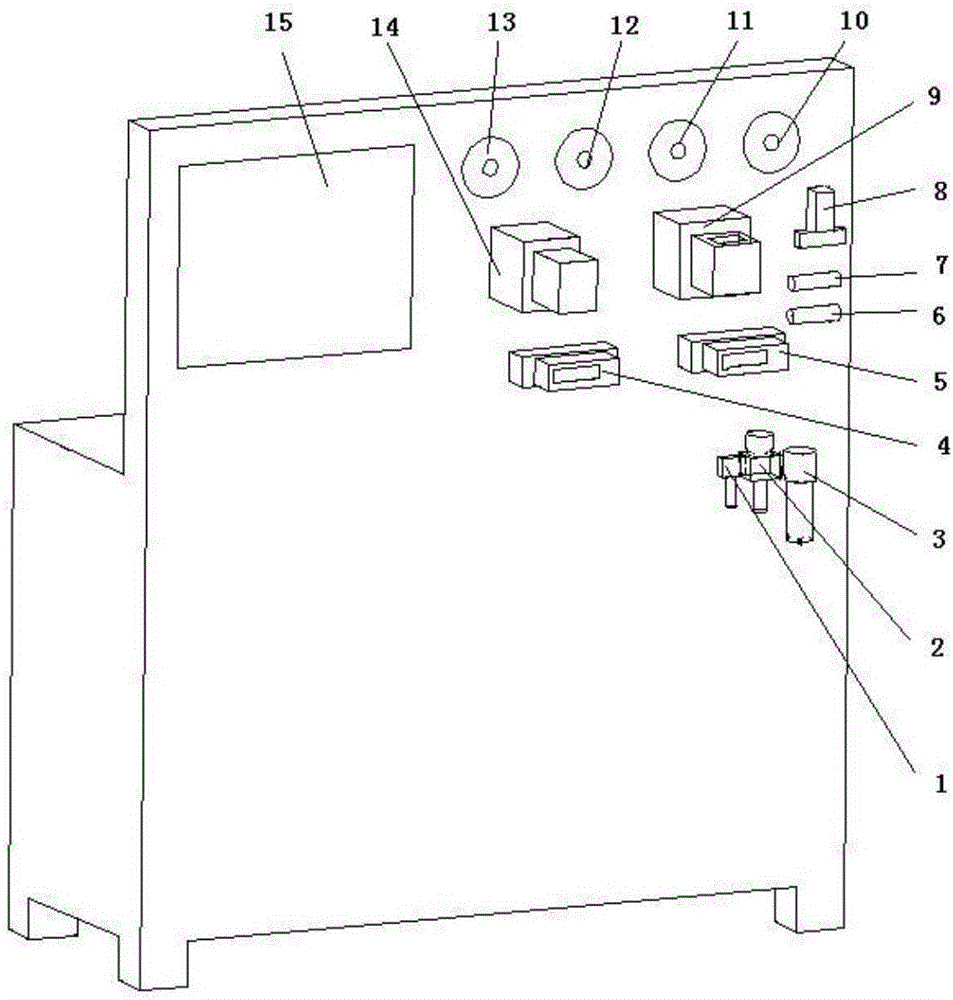

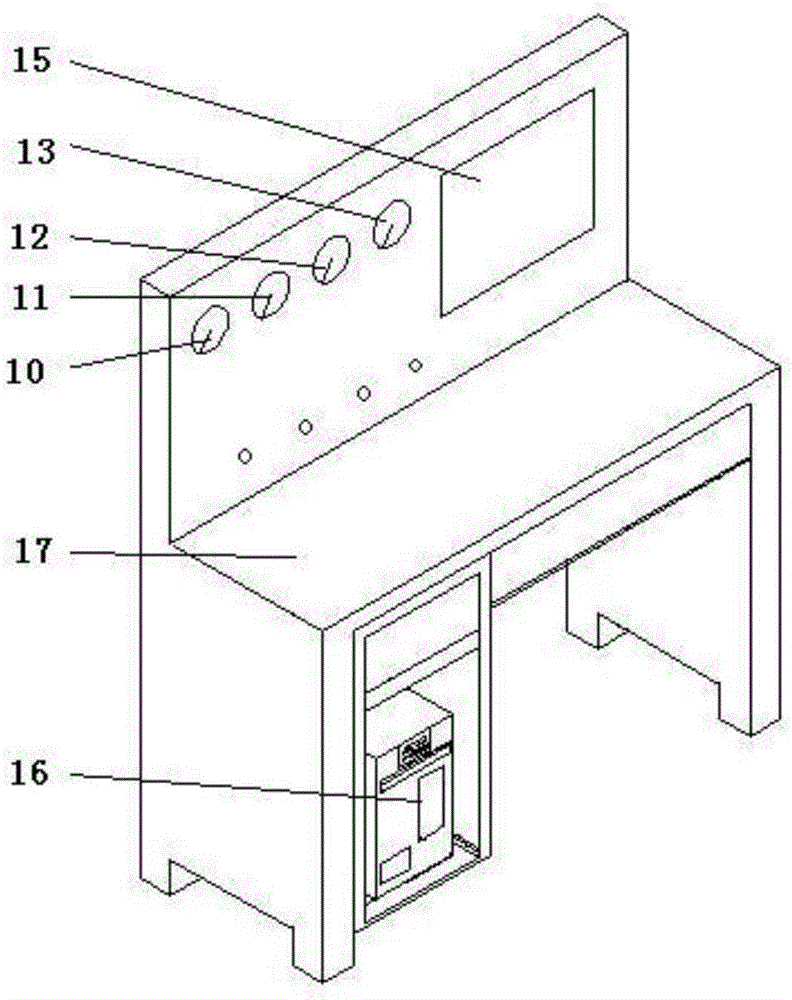

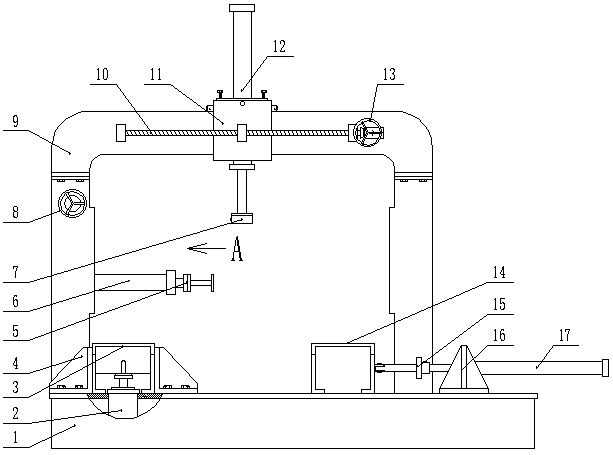

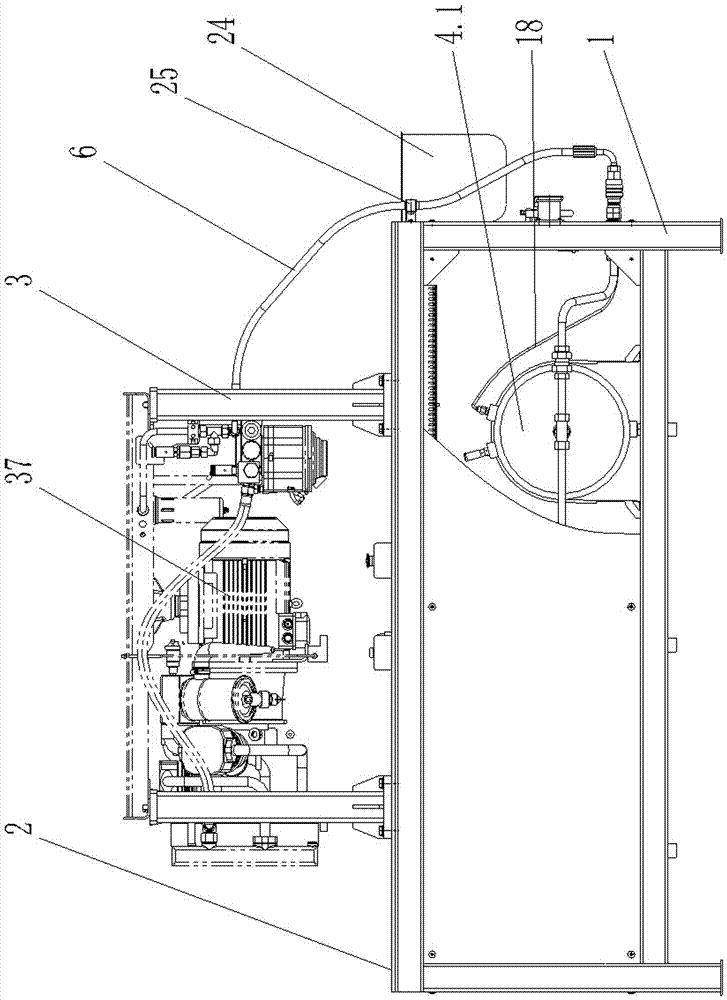

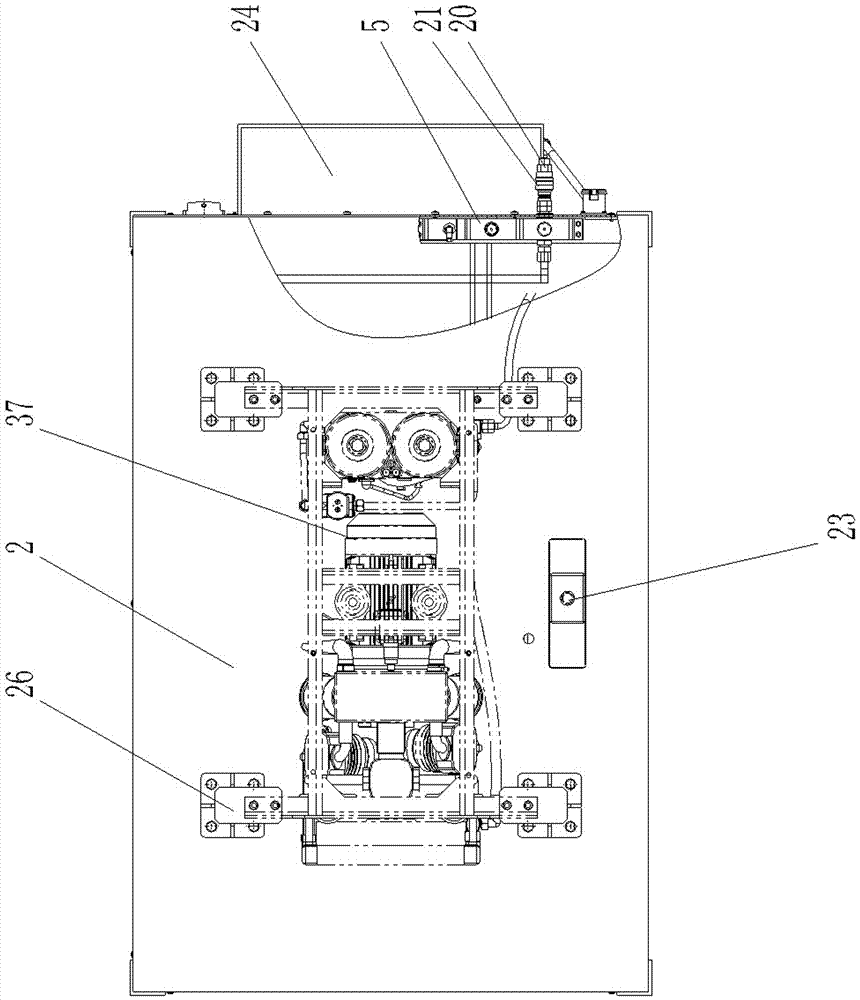

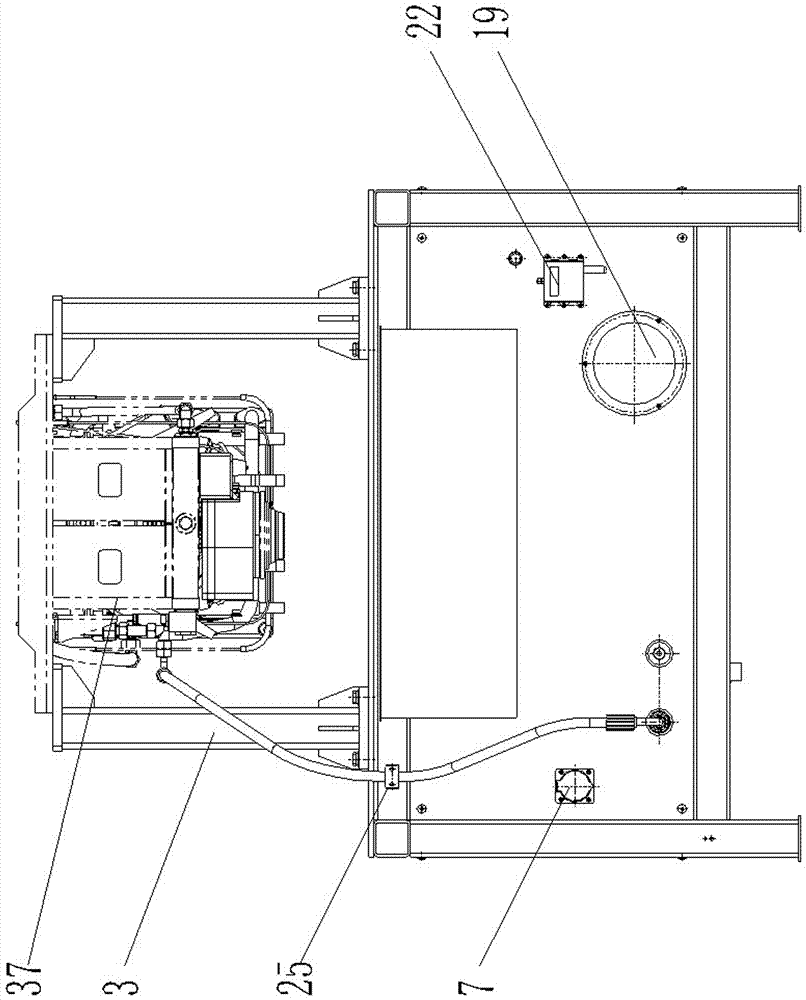

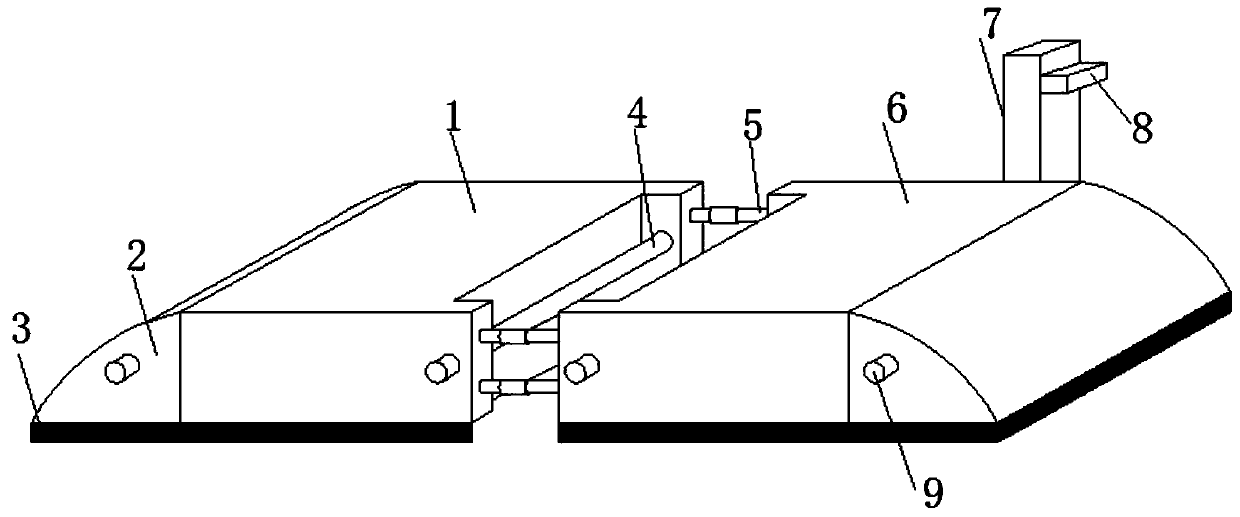

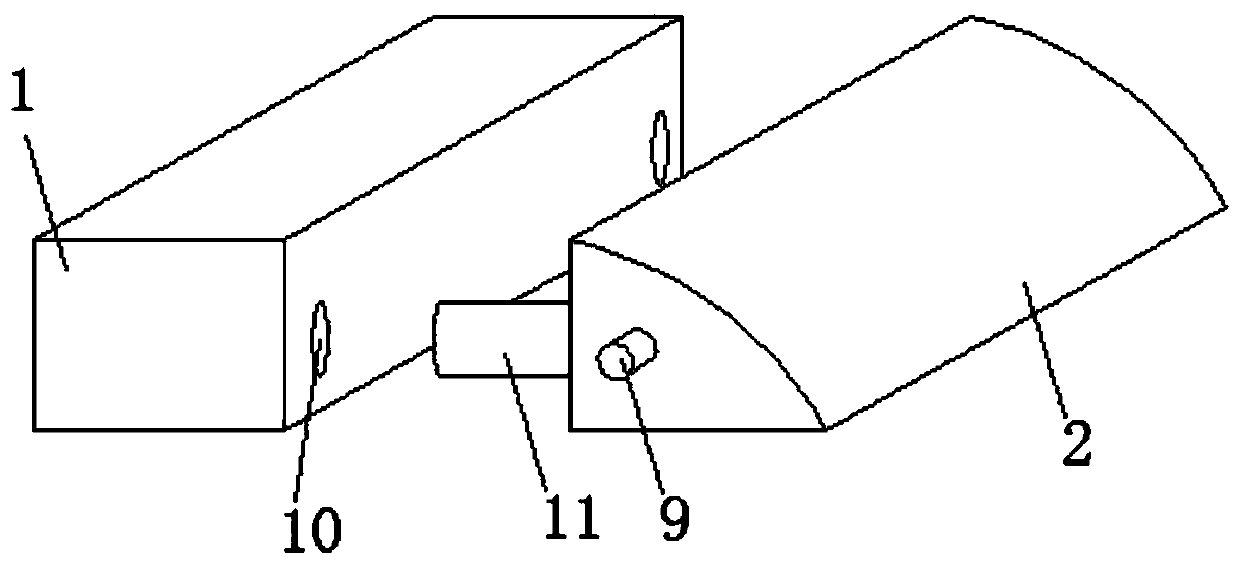

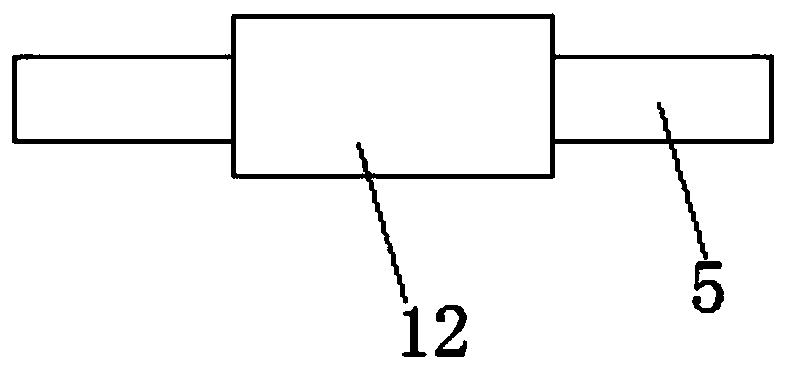

Modularized air compressor test bench

ActiveCN107503929AReliable groundingReliable security protectionPump testingPositive-displacement liquid enginesModularityAirflow

The invention relates to an air compressor test bench, in particular to a modularized air compressor test bench, and mainly solves the technical problems that the test bench is complex to assemble and is troublesome when required functional accessories are assembled, the accuracy is poor when each parameter is detected, test parameters are inaccurate because air flow leaks easily when the air pressure is high and the like in the prior art. The modularized air compressor test bench comprises a machine frame (1); a main bench surface (2) is arranged on the machine frame (1); supporting posts (3) which can fix the air compressor are fixed to the main bench surface; more than two air cylinders are arranged at the lower part of the machine frame; each air cylinder is connected with a module valve plate (5); each module valve plate is connected with the air compressor through a hose (6); and a three-phase four-wire socket (7) is arranged on the machine frame.

Owner:CSR HANGZHOU RAIL TRANSIT

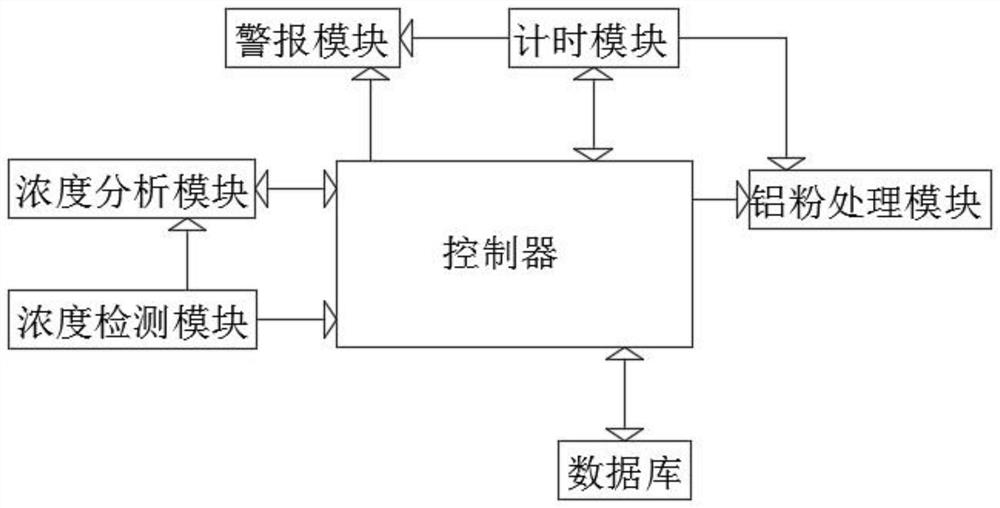

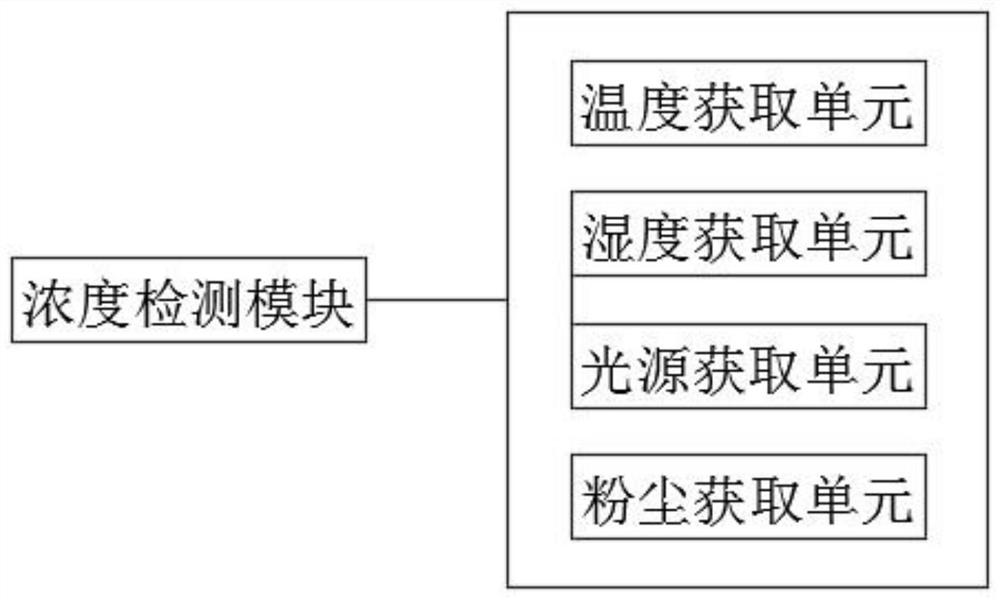

Lead powder treatment system for lead storage battery positive grid production workshop

ActiveCN112000028ASolve the problem of lead powder concentration detectionComprehensive performance testingAlarmsParticle suspension analysisData controlAluminium powder

The invention discloses a lead powder processing system for a lead storage battery positive grid production workshop. The lead powder processing system comprises a controller, a database, a concentration detection module, a concentration analysis module, a timing module, an aluminum powder processing module and an alarm module. The concentration detection module is used for monitoring aluminum powder data in a lead storage battery positive grid production workshop in real time; the concentration analysis module receives and analyzes the aluminum powder data; the controller receives the aluminum powder data and an analysis result of the aluminum powder data, and carries out comparative analysis on the aluminum powder data and preset aluminum powder data in a database; the alarm module receives an instruction sent by the controller to generate alarm sound, and the aluminum powder processing module receives the control instruction and then carries out aluminum powder processing work. According to the design, the lead storage battery positive grid production workshop is divided into a plurality of small areas, so that the detection of the lead powder concentration detection device in the lead storage battery positive grid production workshop is more comprehensive, and the problem that the lead powder concentration detection is generally carried out on the production workshop in a large range in the prior art is solved.

Owner:JIESHOU HUAYU POWER SUPPLY

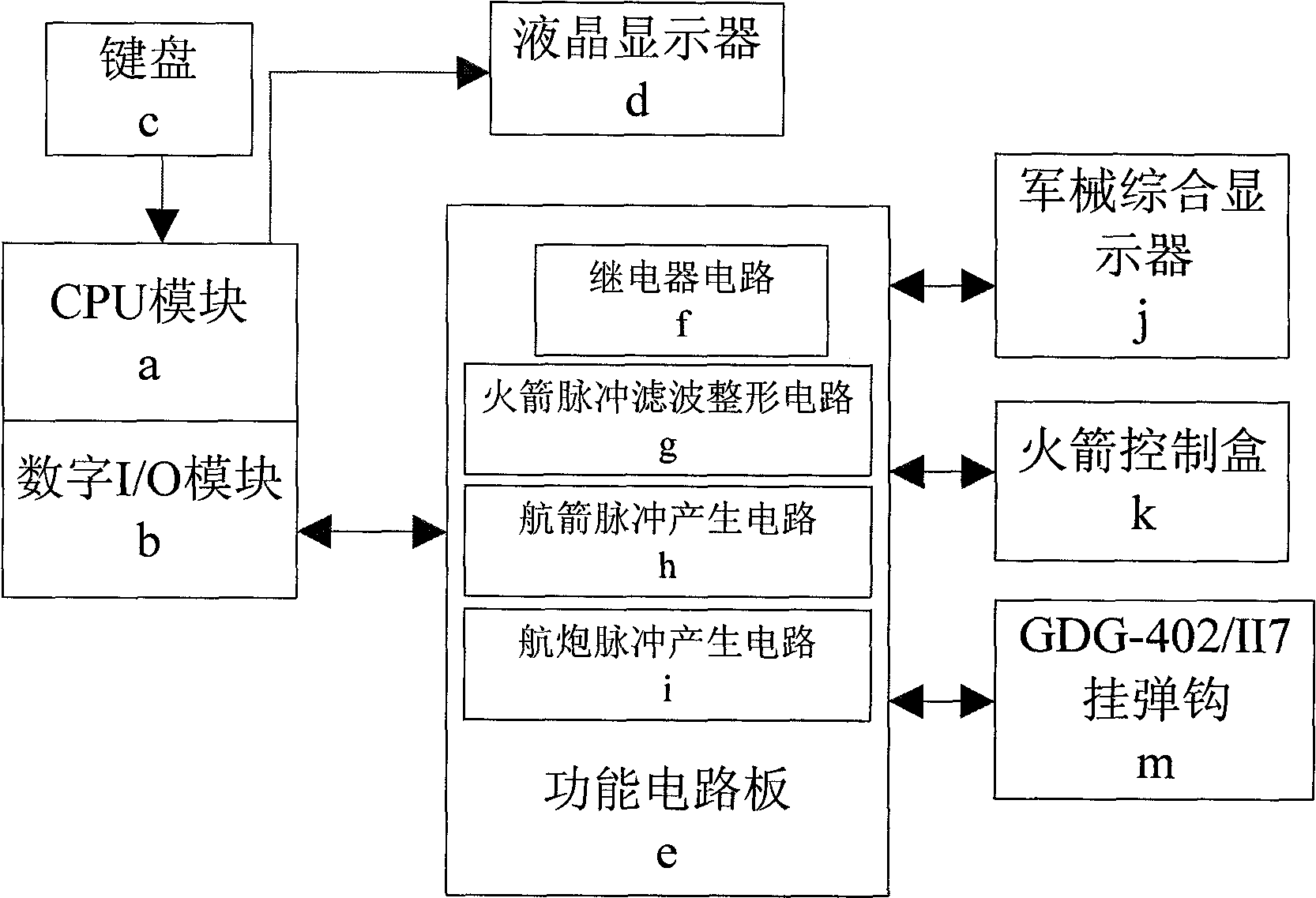

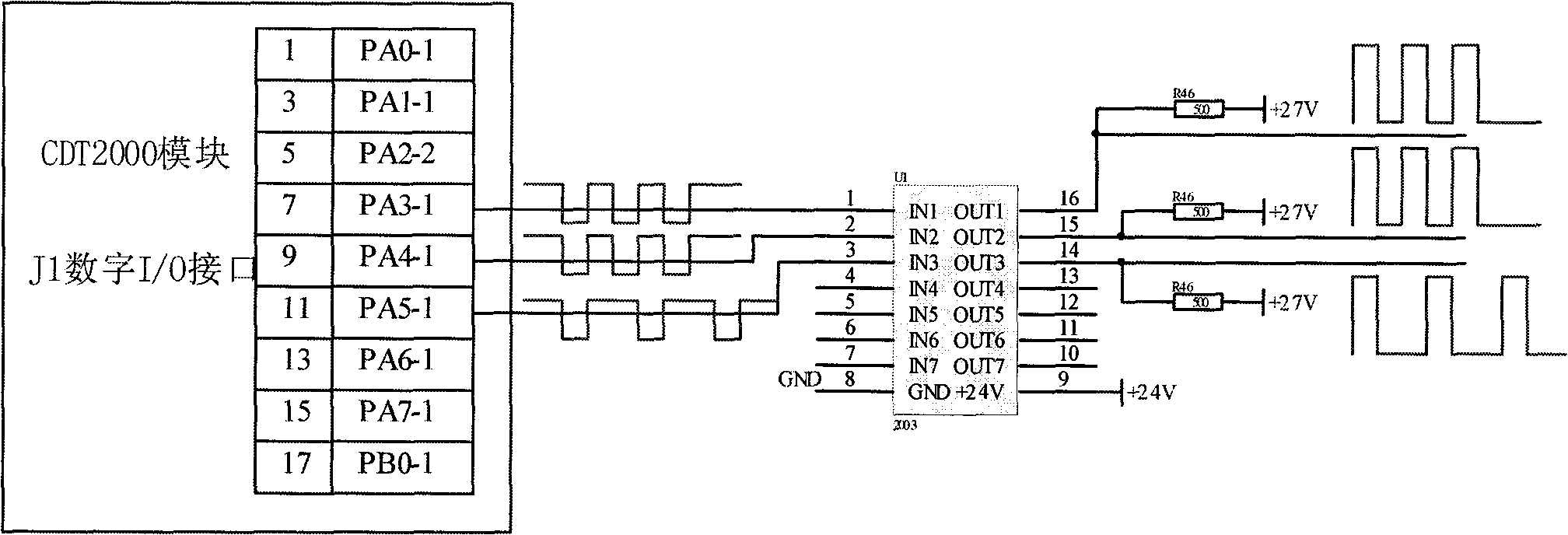

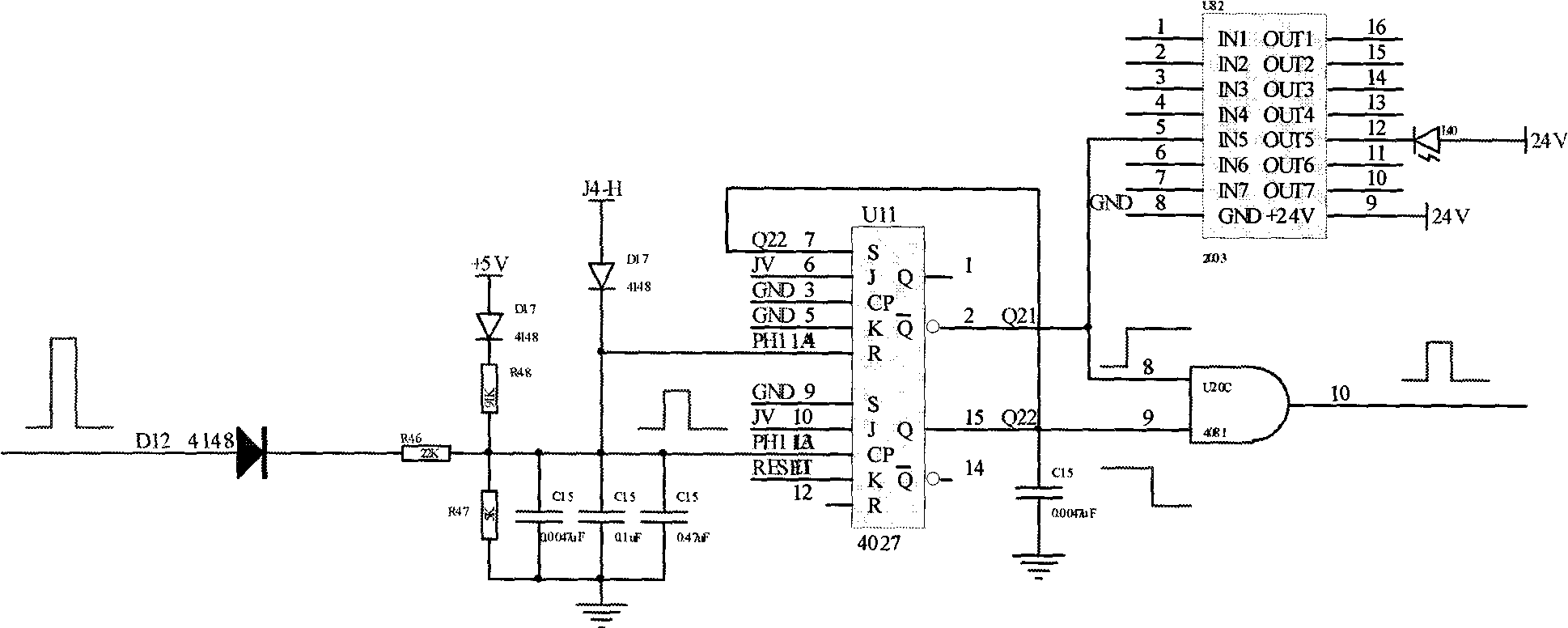

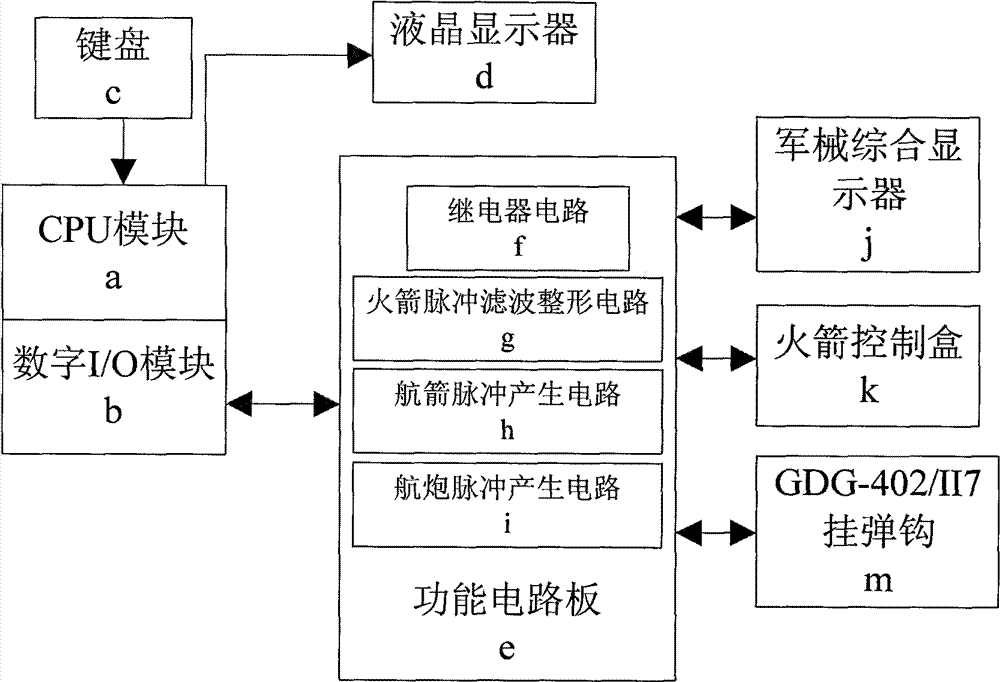

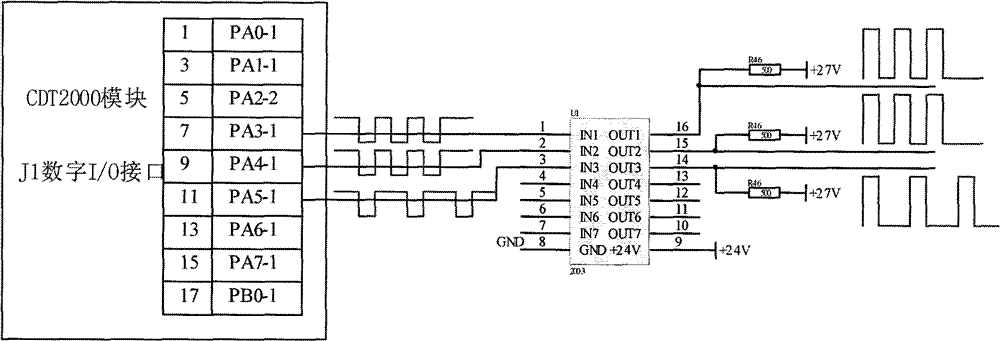

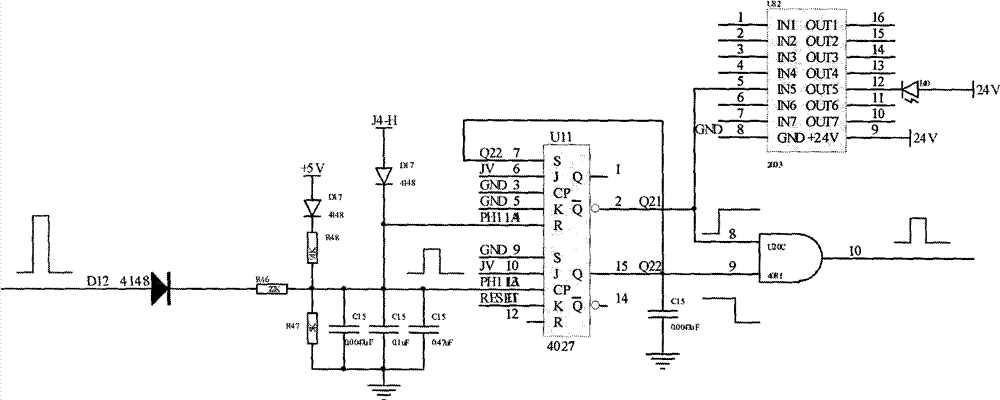

Comprehensive detection device for ordnance

ActiveCN102102968AComprehensive performance testingPerfect analog signalAmmunition testingAircraft components testingComputer moduleRocket

The invention relates to a comprehensive detection device for ordnance. The device comprises a PC104 control subsystem and a functional circuit board, wherein the PC104 control subsystem comprises a central processing unit (CPU) module and a digital input / output (I / O) module; and the functional circuit board comprises a relay circuit, a rocket pulse filtering shaping circuit, an aerial rocket pulse generating circuit and an aerial cannon pulse generating circuit, and is connected with the digital I / O module and the CPU module. Compared with the prior art, the device has the advantages that: performance is tested comprehensively, the device is easy to operate during detection, and the like.

Owner:上海凯迪克航空工程技术有限公司 +1

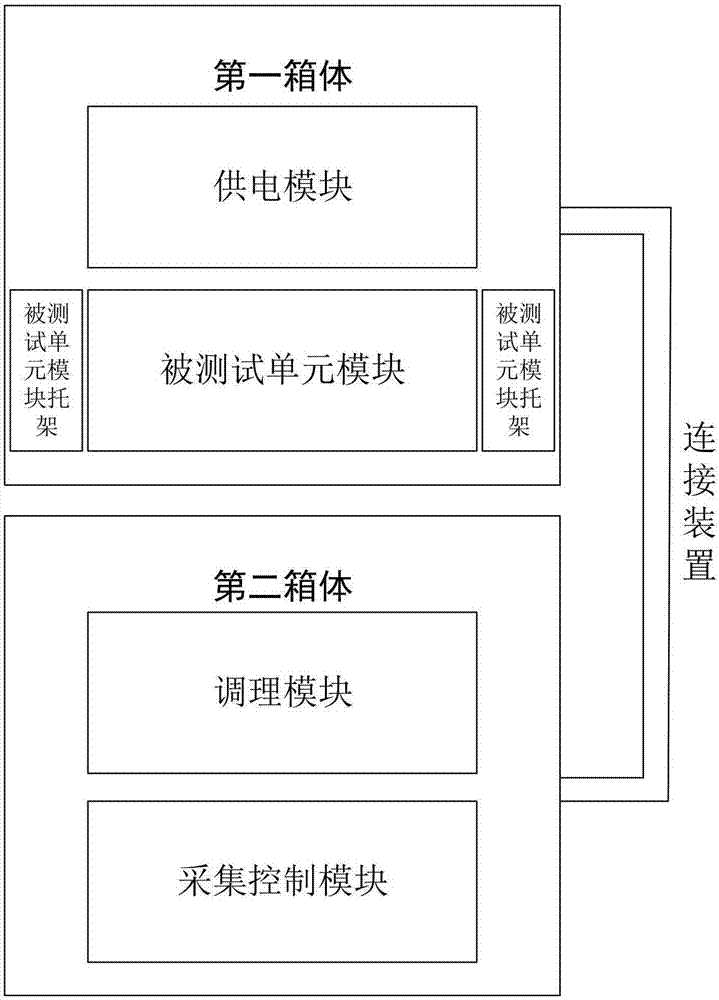

Testing device for aircraft brake controller

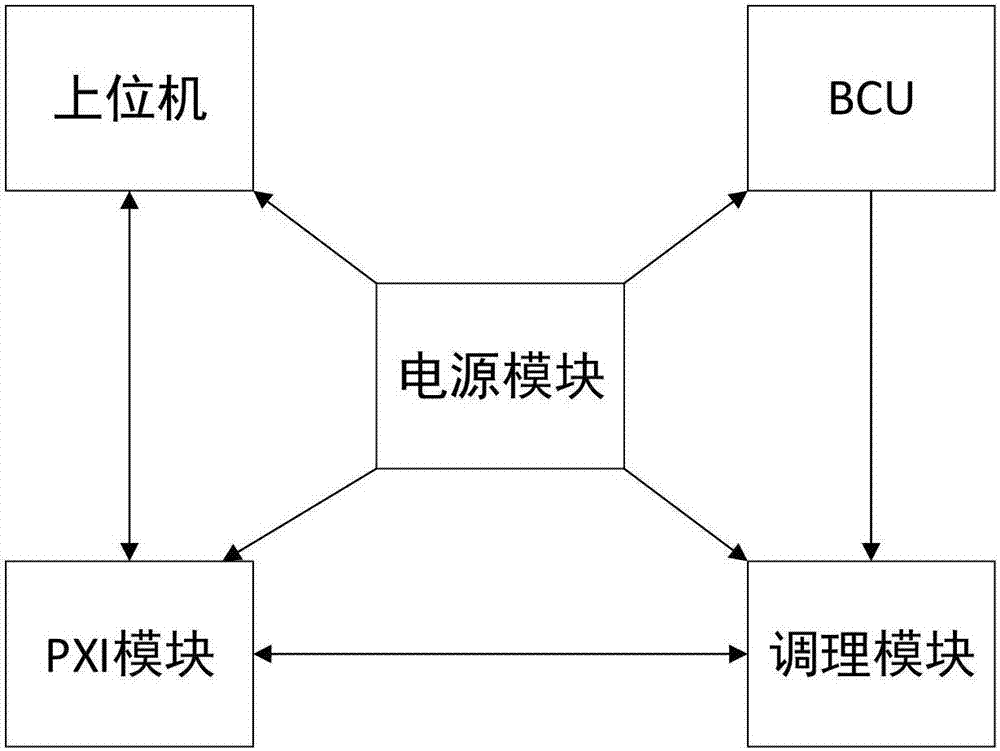

InactiveCN106933216AComprehensive performance testingImprove portabilityElectric testing/monitoringControl signalComputer module

The present invention provides a testing device for an aircraft brake controller. The testing device comprises a power supply module for supplying power to the testing device, multiple tested unit module brackets used for removably installing multiple tested unit modules, an acquisition control module used for collecting and controlling signals from the multiple tested unit modules and a sensor in an aircraft, and a conditioning module used for switching and conditioning signals transmitted between the acquisition control module and the multiple tested unit modules and the sensor, wherein the power supply module and the multiple tested unit module brackets are installed in a first box, the conditioning module and the acquisition control module are installed in a second box body, the first box body and the second box body are stacked in use, and the modules installed in the first box body and the second box body are connected through a connection device.

Owner:BEIHANG UNIV

Optical line terminal equipment test box

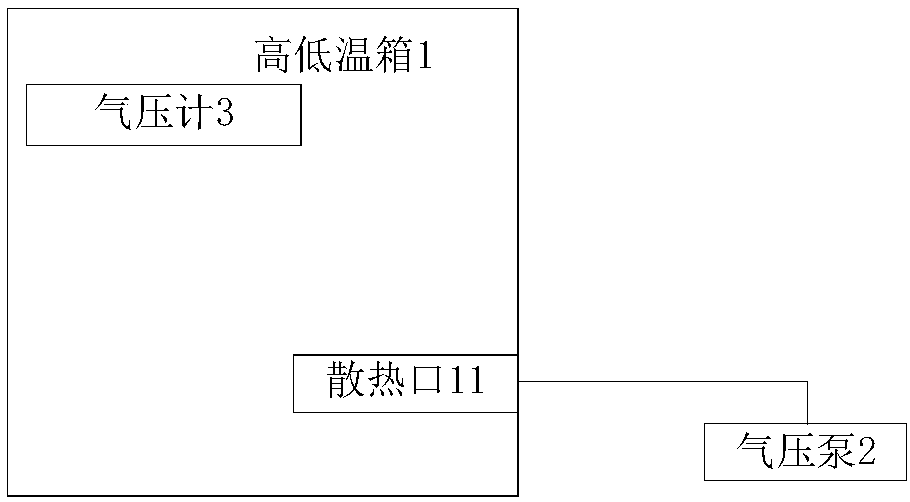

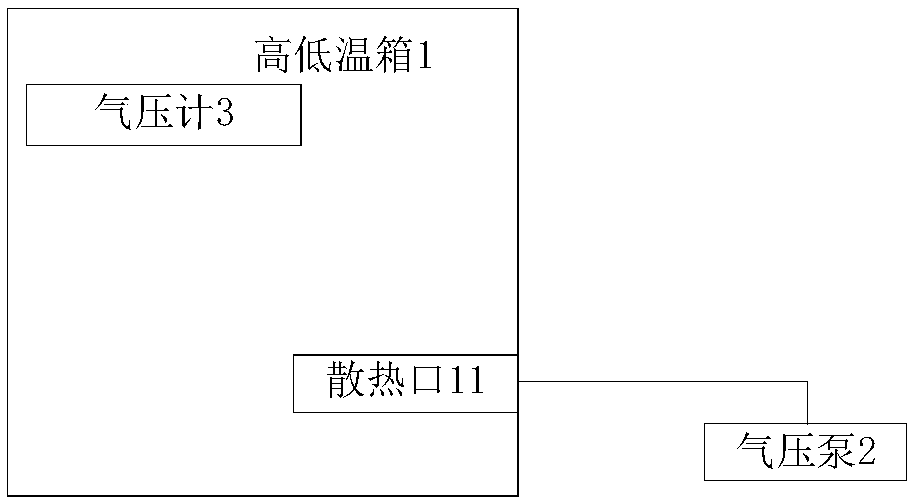

PendingCN109985671AMeet the needs of performance testingShorten adjustment timeHeating or cooling apparatusAir-pressure/air-lock chambersTerminal equipmentEngineering

The invention relates to an optical line terminal equipment test box including a high-low temperature box (1) used for placing a switch to be tested. The high-low temperature box (1) is provided witha heat dissipation port (11). The test box also includes an air pressure pump (2), an air outlet pipeline of the air pressure pump (2) is detachably connected with the heat dissipation port (11), andwhen the air outlet pipeline is connected with the heat dissipation port (11), the high-low temperature box (1) is in a sealed state. Compared with the prior art, the test box disclosed by the invention has high-low temperature simulation and high-low pressure simulation functions, and meets the requirement of the current optical line terminal performance test; a barometer is arranged in the high-low temperature box, the high-low temperature box is made of transparent organic materials, the air pressure state in the box and the physical state of the terminal equipment can be observed at any time, parameter adjusting time is saved, and testing times are reduced.

Owner:SHANGHAI GONGLIAN COMM INFORMATION DEV

Overall performance testing rack of numerical control ultrasonic cutting sound main shaft

InactiveCN103323223BEasy to synthesizeFor subsequent analysisMachine part testingNumerical controlCombined test

Owner:HANGZHOU DIANZI UNIV

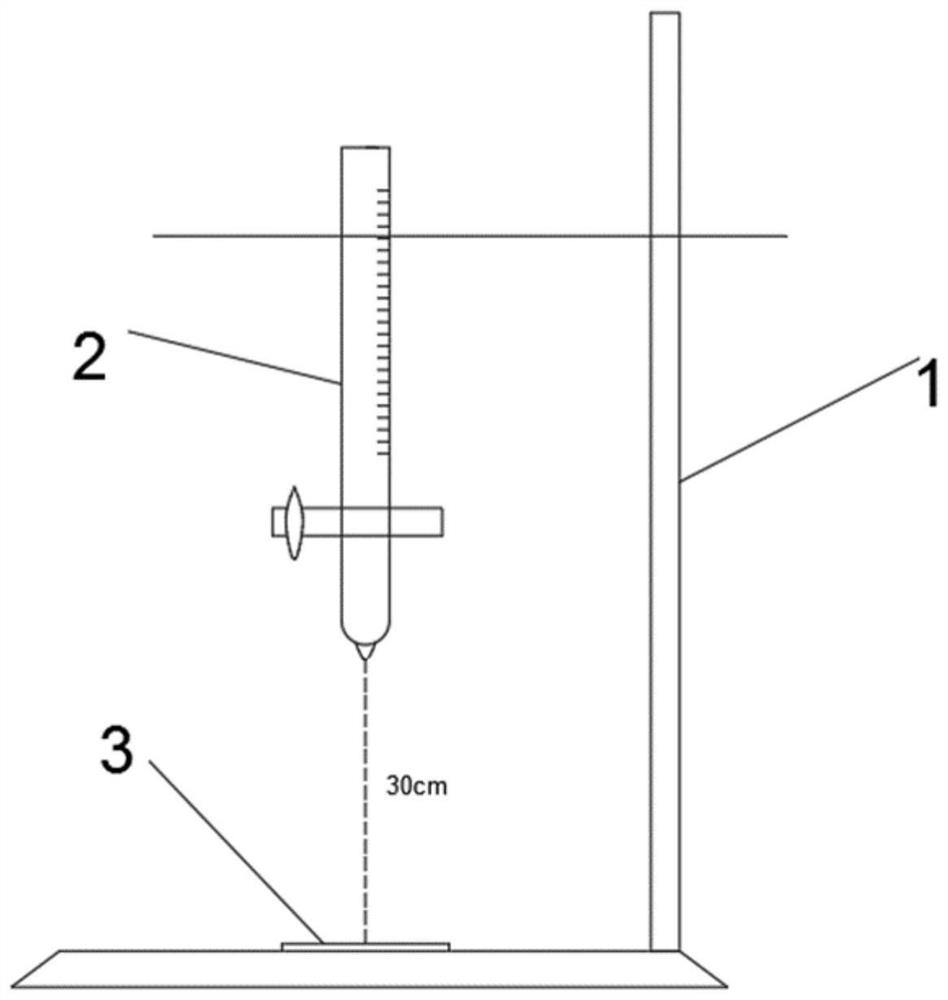

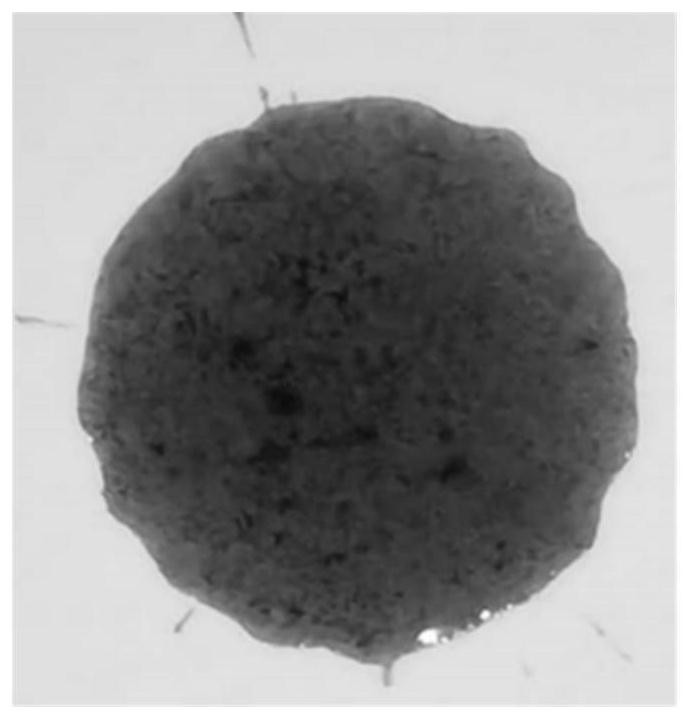

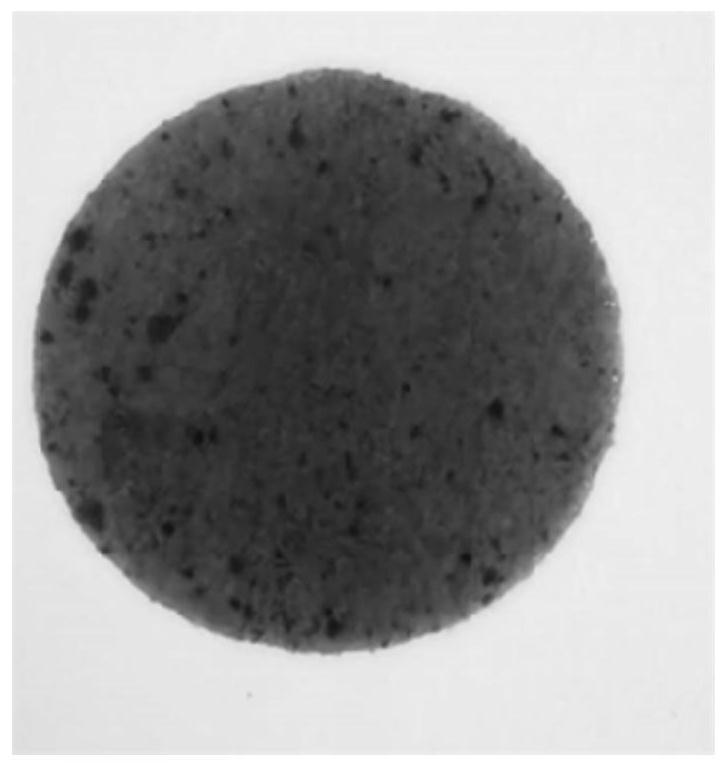

Paper absorption comprehensive performance testing method, tester and application

ActiveCN112611669AAbsorption affects the sameIntuitively feel the apparent absorption and diffusionSurface/boundary effectPermeability/surface area analysisIodine solutionsPhysical chemistry

The invention discloses a paper absorption comprehensive performance testing method which is characterized by comprising the following steps of fixing a burette filled with a povidone-iodine solution on a workbench, vertically dropping a certain amount of povidone-iodine solution at a fixed height, dropping the povidone-iodine solution onto to-be-detected paper placed on the workbench, shooting and recording the apparent diffusion absorption conditions of the povidone-iodine solution droplets of all brands of paper at the same time interval, after complete absorption, dropping a certain amount of solution at the same position until complete absorption is not achieved, sucking away the surface solution with absorbent paper, weighing the increased weight, and achieving comprehensive performance testing. The reddish-brown povidone-iodine solution is adopted, so that the apparent absorption and diffusion conditions of the solution on the paper can be more easily and visually sensed, the absorption uniformity is quickly reflected and serves as the most important performance index, and the absorption performance of the paper is comprehensively considered from the aspects of the absorption uniformity, the absorption rate, the absorption multiplying power and the like.

Owner:湖北华工图像技术开发有限公司

A detection device for automobile tires

ActiveCN108918166BChange impactChange driving conditionsVehicle tyre testingMeasuring instrumentStructural engineering

The invention discloses a detection device for automobile tires. The technical problems that existing automobile tires need to adopt various experiment instruments during detection, and the conditionsof different road surfaces cannot be simulated during tire driving detection can be solved. The detection device comprises a first base, a second base, cushioning pads and extrusion plates; one end of the first base is connected with the second base; one end of the first base and one end of the second base are connected with the cushioning pads with the circular-arc-shaped tops correspondingly; the middle ends in grooves are transversely connected with bolt rods, and the middles of the bolt rods are sleeved with limiting plates; the tops of mounting plates are connected with the uneven extrusion plates, and a sleeve is connected between two opposite screw rods at the ends of the first base and the second base; and a speed measuring instrument is mounted on one side of the second base. Thetires are detected through a method and the device, and the damage conditions of the tires travelling on the different road surfaces or same road surface at different speeds or at the same speed canbe accurately measured.

Owner:去保养(北京)科技发展有限公司

Ultrasonic cutting sound spindle comprehensive performance test analysis system

InactiveCN103344419BReduce the influence of human random factorsImprove stabilityMachine part testingNumerical controlTest analysis

Owner:HANGZHOU DIANZI UNIV

Comprehensive detection device for ordnance

ActiveCN102102968BComprehensive performance testingPerfect analog signalAmmunition testingAircraft components testingComputer moduleRocket

The invention relates to a comprehensive detection device for ordnance. The device comprises a PC104 control subsystem and a functional circuit board, wherein the PC104 control subsystem comprises a central processing unit (CPU) module and a digital input / output (I / O) module; and the functional circuit board comprises a relay circuit, a rocket pulse filtering shaping circuit, an aerial rocket pulse generating circuit and an aerial cannon pulse generating circuit, and is connected with the digital I / O module and the CPU module. Compared with the prior art, the device has the advantages that: performance is tested comprehensively, the device is easy to operate during detection, and the like.

Owner:上海凯迪克航空工程技术有限公司 +1

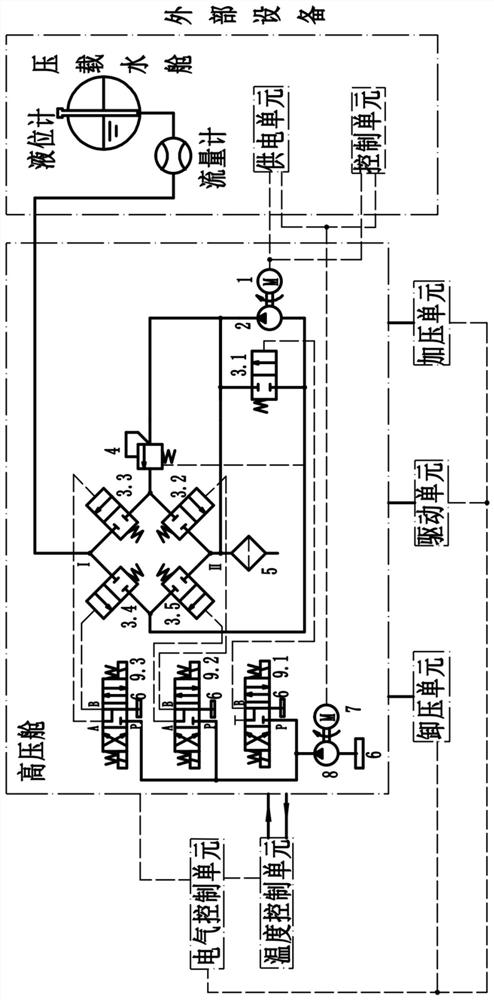

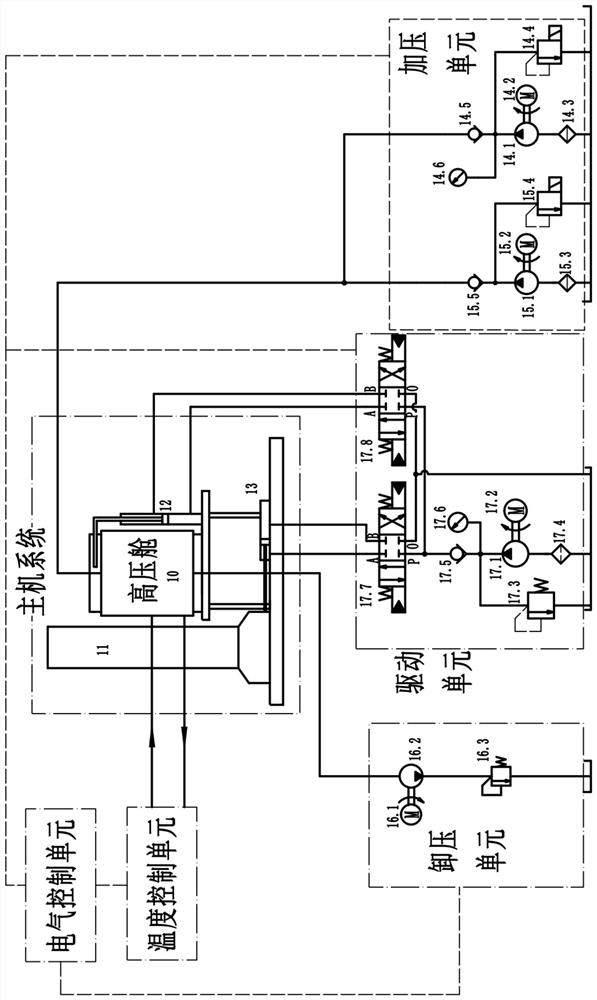

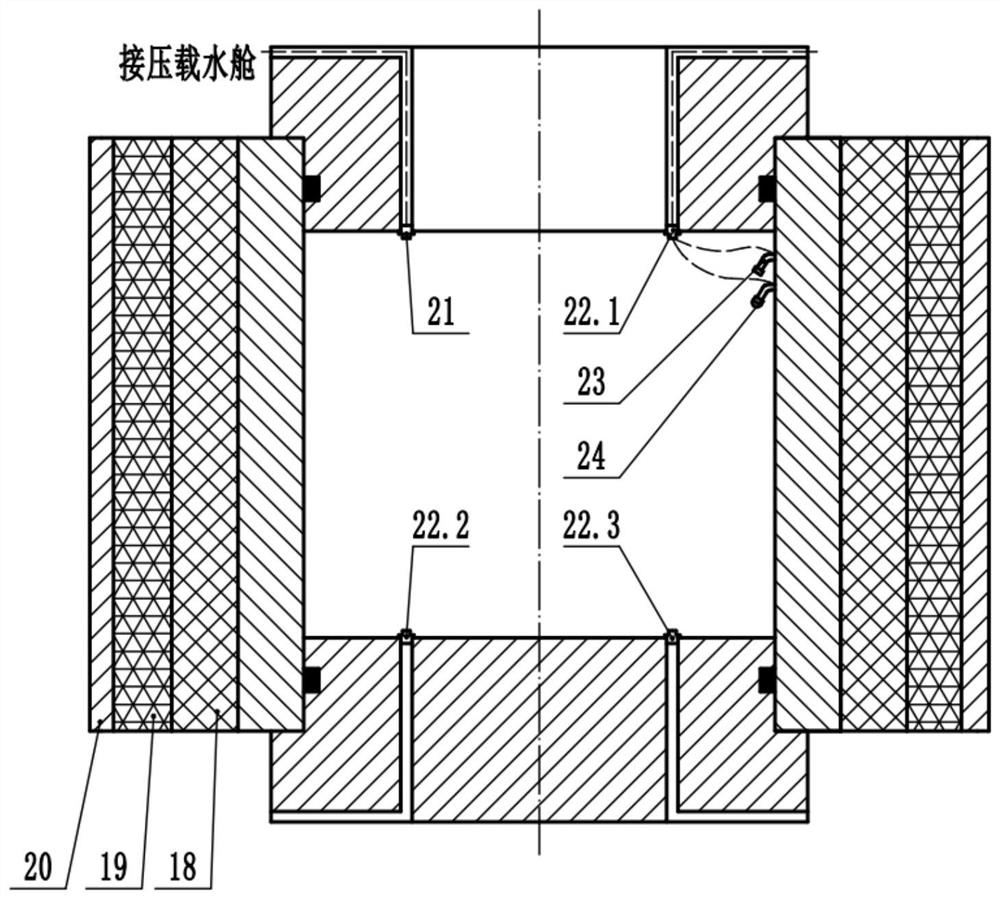

A full-condition test equipment and test bench for a full-sea depth buoyancy regulation system

ActiveCN112065791BComprehensive performance testingReduce testing costsFluid-pressure actuator testingServomotor componentsBuoyancy regulationUltra high pressure

The invention discloses a full-sea deep buoyancy adjustment system full-working-condition test equipment and a test bench, which are used for performance testing of the full-sea deep buoyancy control system in a simulated deep-sea environment, and belong to the field of full-work-condition testing of deep-sea equipment. In the present invention, the motor, seawater pump, integrated control valve group, and hydraulic source are placed in the high-pressure chamber of the host system of the full-sea deep environment simulation test bench, and the power supply and control of the motor and hydraulic source in the ultra-high pressure environment are realized through watertight connectors. The ballast water tank, power supply unit and control unit are placed outside the hyperbaric chamber, and the ballast water tank is connected to the valve group to be tested in the hyperbaric chamber, so that it is more convenient and comprehensive to test the performance of the buoyancy adjustment system from the outside , no supporting equipment such as ballast tanks and batteries that can withstand ultra-high external pressure, greatly saving test costs, reducing test risks, and more comprehensive performance testing. The test bench can simulate 11,000-meter deep-sea ultra-high pressure, strong corrosion and ultra-low temperature environment .

Owner:HUAZHONG UNIV OF SCI & TECH

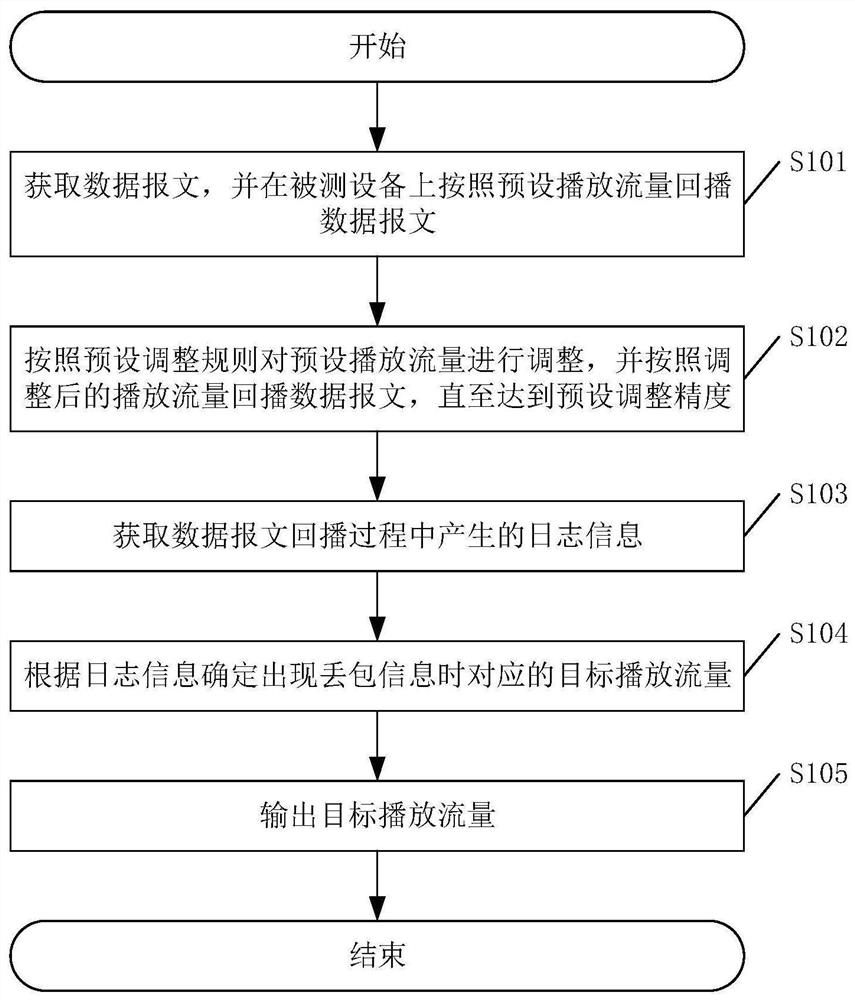

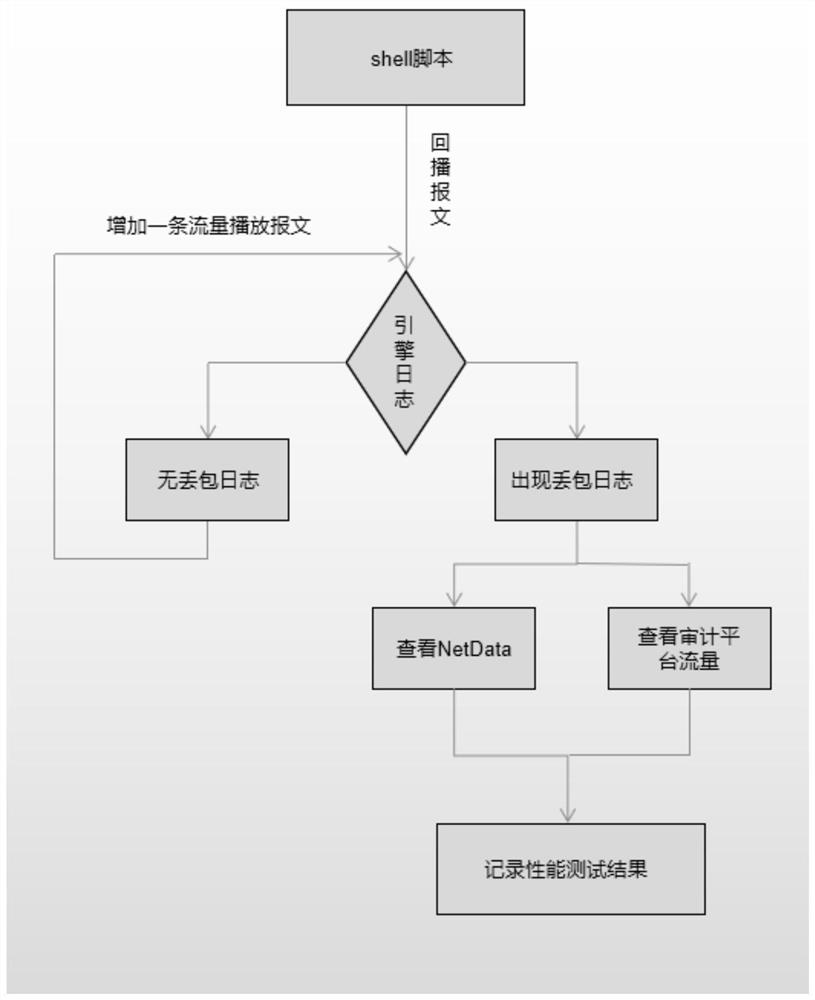

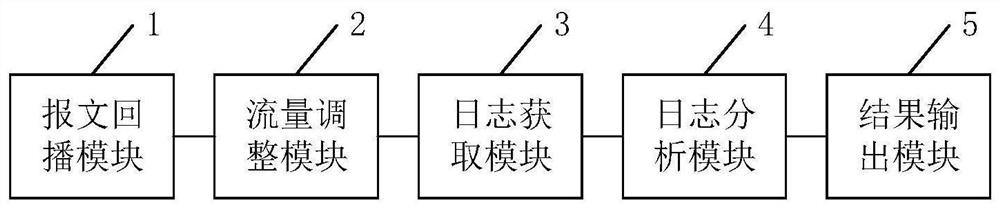

Equipment performance test method and device and related equipment

ActiveCN113542066AComprehensive performance testingLow equipment requirementsData switching networksTotal factory controlPacket lossEquipment under test

The invention discloses an equipment performance test method, which comprises the following steps: acquiring a data message, and replaying the data message on tested equipment according to preset playing traffic; adjusting the preset playing traffic according to a preset adjustment rule, and replaying the data message according to the adjusted playing traffic until the preset adjustment precision is satisfied; obtaining log information generated in a data message playback process; determining corresponding target playing traffic when packet loss information appears according to the log information; and outputting the target playing traffic. According to the equipment performance test method, more comprehensive equipment performance detection can be realized, and the performance detection cost is reduced. The invention further discloses an equipment performance test device and system and a computer readable storage medium which all have the above beneficial effects.

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

Serial test method and test tool

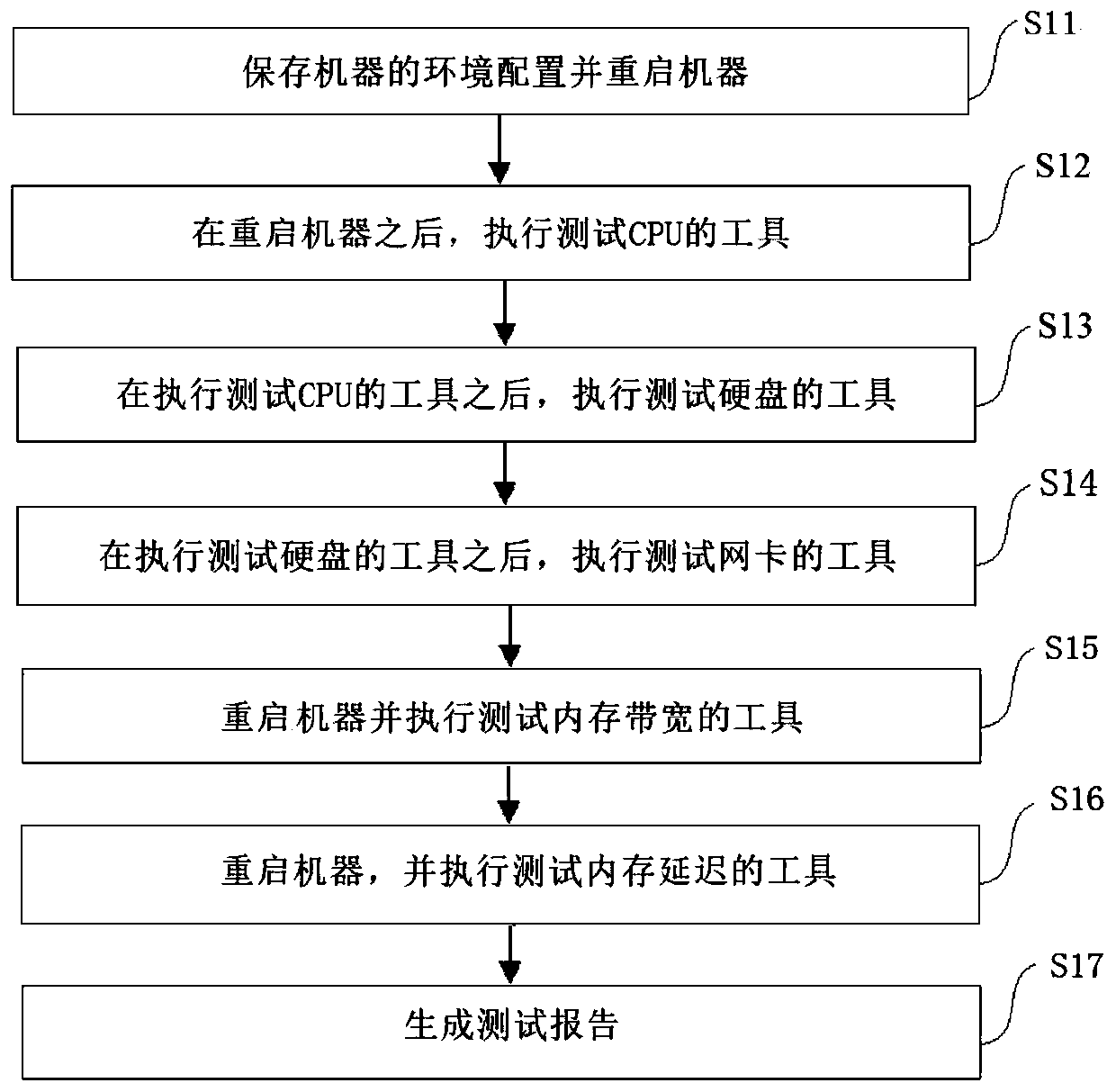

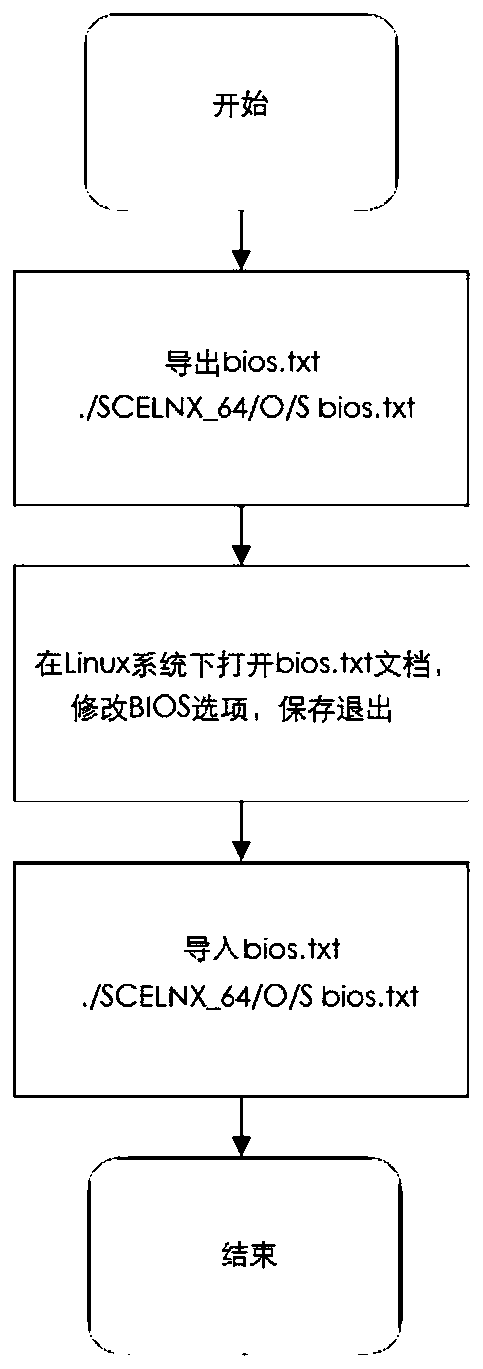

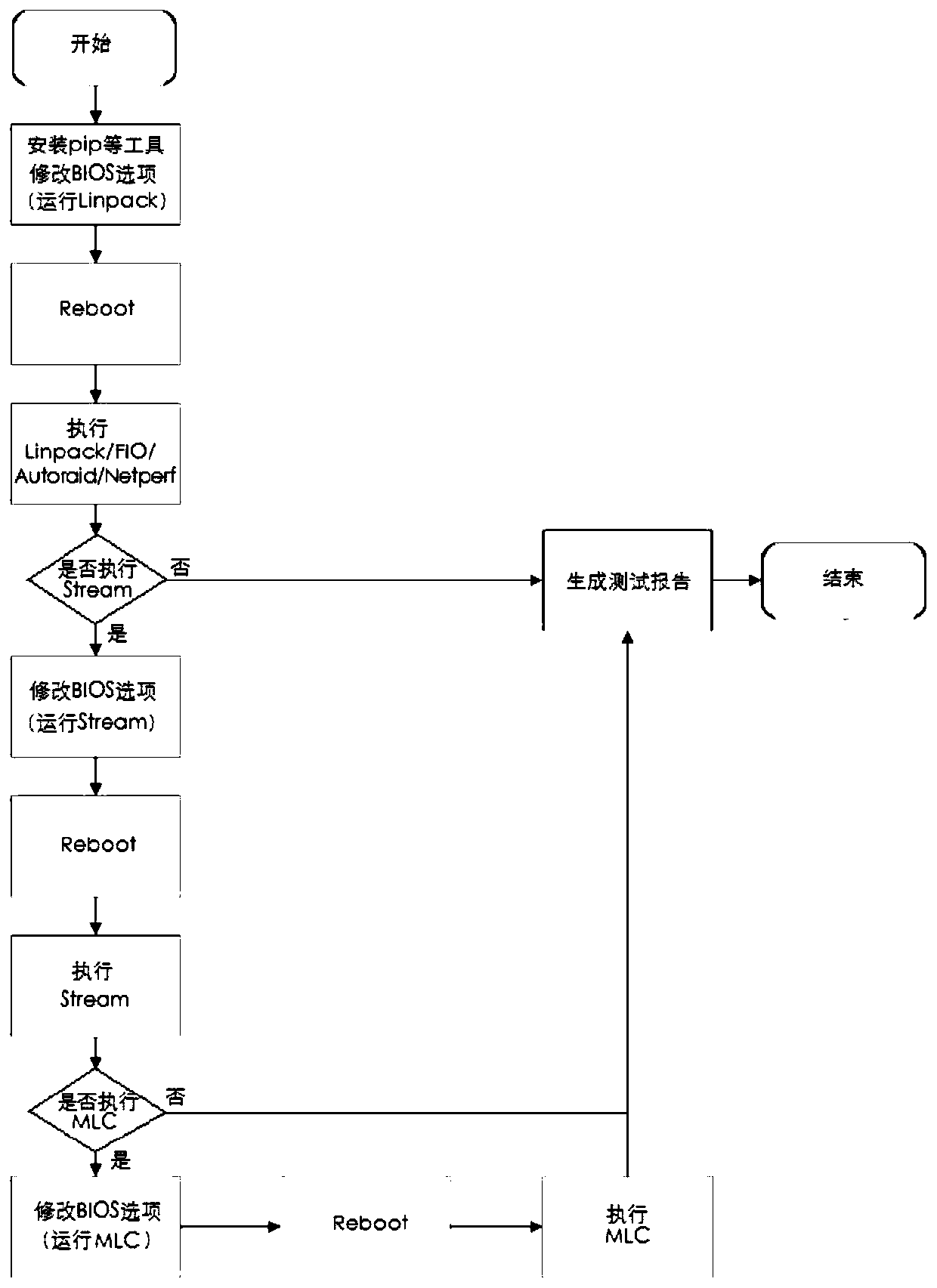

PendingCN111176915ATest professional and comprehensiveProfessional and comprehensive performance testingFaulty hardware testing methodsTerm memoryMemory bandwidth

The invention discloses a serial test method and a test tool. The test method comprises the following steps: storing environment configuration of a machine and restarting the machine; executing a toolfor testing the CPU after the machine is restarted; after executing the tool for testing the CPU, executing the tool for testing the hard disk; after executing the tool for testing the hard disk, executing the tool for testing the network card; restarting the machine and executing a tool for testing the memory bandwidth; and restarting the machine, and executing a tool for testing the memory delay.

Owner:曙光信息系统(辽宁)有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com