Paper absorption comprehensive performance testing method, tester and application

A technology of comprehensive performance testing and comprehensive performance, applied in the field of paper absorption comprehensive performance testing, can solve the problems of water that cannot represent the rapid absorption of paper, the water absorption rate of paper cannot be determined, and it cannot represent the adaptability of paper printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

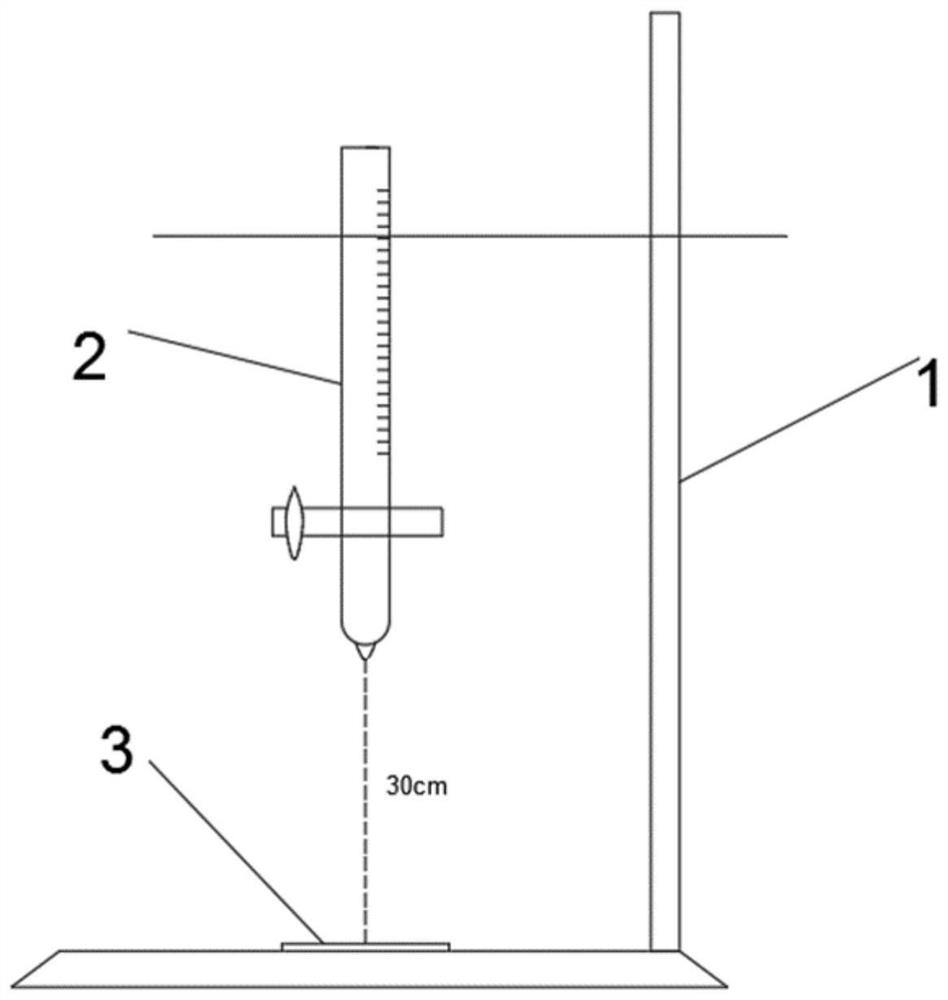

[0067] Drop a drop of 0.05mL povidone-iodine solution at a height of 30cm on the A4 size Asian pulp-coated white cardboard, and start timing when the solution falls on the paper. After a time interval of 10 seconds, quickly take pictures of the solution on the Asian pulp paper According to the apparent diffusion and absorption on the surface, continue to add the solution dropwise. After the solution cannot be completely absorbed, absorb the solution with absorbent paper, weigh its weight and calculate the weight increase before and after, and repeat this operation on three white cardboards.

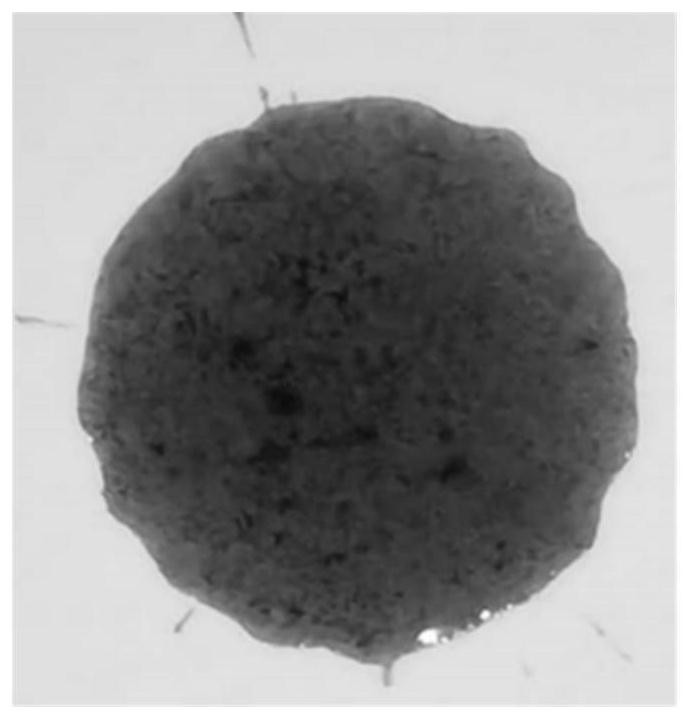

[0068] Such as figure 2 As shown, the comprehensive results show that on the Asian pulp white cardboard, the droplets spread into a regular circle, the entire circular area is dark yellow, and there are very few black spots. Among the six example papers, the absorption is the best, and the records before and after the test .

Embodiment 2

[0070] Drop a drop of 0.05mL povidone-iodine solution on the A4 size Golden Sun coated white cardboard at a height of 30cm, and start timing when the solution falls on the paper. According to the apparent diffusion and absorption on the surface, continue to add the solution dropwise. After the solution cannot be completely absorbed, absorb the solution with absorbent paper, weigh its weight and calculate the weight increase before and after, and repeat this operation on three white cardboards.

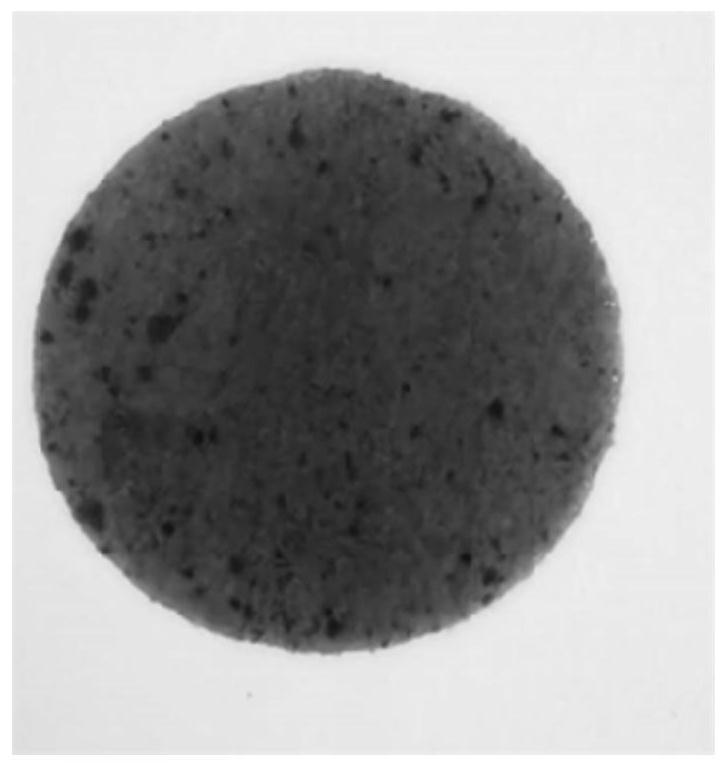

[0071] Such as image 3 As shown, the comprehensive results show that on the Golden Sun white cardboard, the droplets spread into a relatively regular circle, and the entire circular area is dark yellow, with a few black spots, which are slightly more than Asian pulp.

Embodiment 3

[0073] Drop a drop of 0.05mL povidone-iodine solution at a height of 30cm on the A4 size Hongta coated white cardboard, and start timing when the solution falls on the paper. According to the apparent diffusion and absorption, continue to add the solution dropwise. After the solution cannot be completely absorbed, absorb the solution with absorbent paper, weigh its weight and calculate the weight increase before and after, and repeat this operation on three white cardboards.

[0074] Such as Figure 4 As shown, the comprehensive results show that on the Hongta white cardboard, the droplets spread into a regular circle, and the entire circular area is dark yellow, and there are thick black areas in it, which are more than the golden sun.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com