Enzymolysis oat powder and preparation method thereof

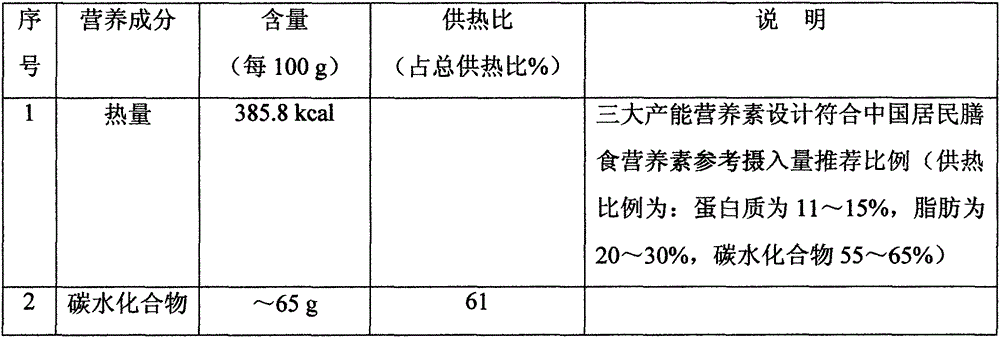

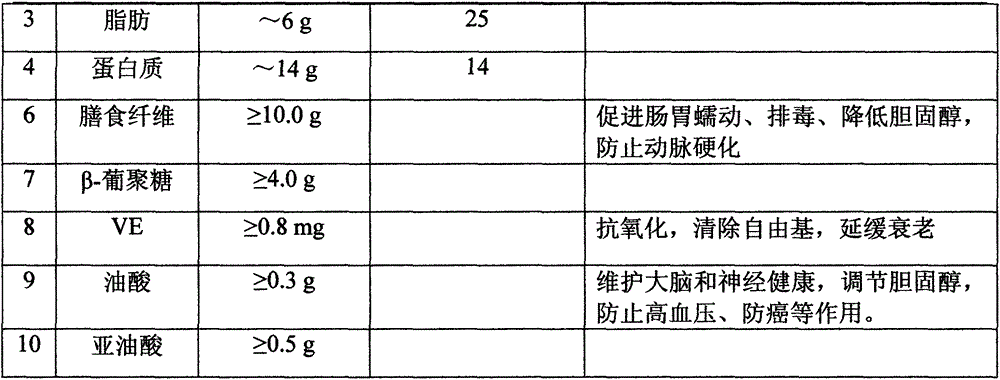

A technology of enzymatically decomposing oat flour and oat flour, which is applied in the field of food processing, can solve the problems of single nutrient, hard and thick seed coat, hardened and agglomerated starch granules, and achieve the effects of lowering blood cholesterol, preventing osteoporosis, and delaying aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The required raw material formula is: oat 300, high-temperature amylase 0.3, compound phosphate 0.27, and the balance is water.

[0057] The preparation method of enzymolysis oat flour of the present invention comprises the following steps:

[0058] 1) Oats are cleaned in a cooking tank. According to the mass ratio, the amount of cleaning water is twice the mass of oats; after cleaning, the waste water is poured to ensure that no foreign matter is mixed into the oats.

[0059] 2) Add 90°C hot water to the cleaned oats (according to the mass ratio, the amount of water added is twice the mass of oats), and add the raw material compound phosphate, turn on the stirring equipment, heat to boil, and keep warm for 30 minutes to ensure that the oats are fully Cooked, no hard grains, white core.

[0060] 3) Add hot water in advance to the enzymolysis tank (according to the mass ratio, the amount of water added is twice the mass of oats), and add 20% of raw material high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com