Two-dimensional perovskite light absorption material and preparation method thereof

A light-absorbing material and perovskite technology, applied in organic chemistry methods, amino compound preparation, chemical instruments and methods, etc., can solve the instability of three-dimensional perovskite light-absorbing materials and two-dimensional perovskite light-absorbing material devices Low efficiency and other problems, to achieve good stability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of a two-dimensional perovskite light-absorbing material, the steps are as follows:

[0023] (1), 1,4-butanediamine (BEA) and 57% hydroiodic acid (HI solution) in stoichiometric molar ratio 1,4-butanediamine:HI=1:2 at room temperature The reaction was stirred for 2 h to obtain 1,4-butanediamine iodine (BEAI 2 ) solution;

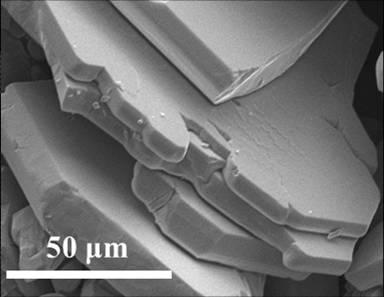

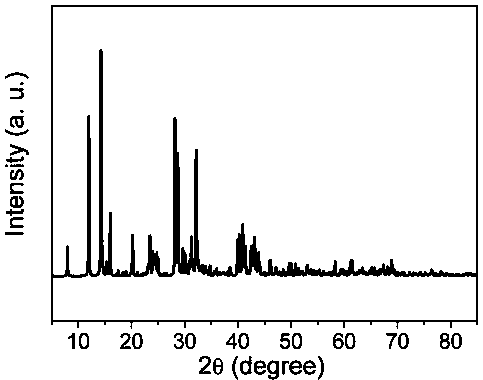

[0024] (2), synthesis (BEA) 0.5 (CH 3 NH 3 ) 3 Pb 3 I 10 Single crystal material: lead acetate (Pb(Ac) 2 ) was dissolved in a mixed solution of hydroiodic acid (HI) with a mass content of 57% of hydroiodic acid and an aqueous solution of hypophosphorous acid with a mass content of 50%, stirred to form a uniform solution, and the temperature was controlled at 60 °C to stir for 1 h; then add iodide To the above solution, then dropwise add 1,4-butanediamine iodine (BEAI 2 ), after the dropwise addition, the temperature was controlled and stirred at 100 ℃ for 1 h; finally, after washing and filtering, (BEA) 0.5 (CH 3 NH 3 ...

Embodiment 2

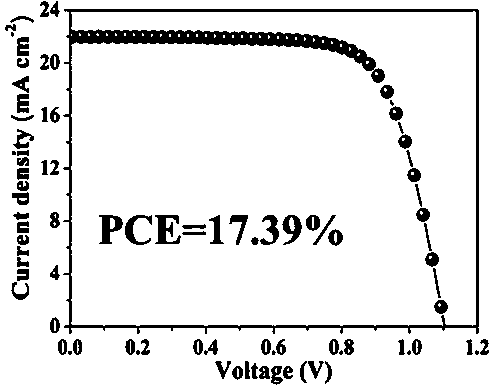

[0029] A preparation method for a perovskite solar cell, the steps are as follows:

[0030] Step S1--dense titanium dioxide (TiO 2 ) film preparation:

[0031] S1.1, ultrasonically clean the FTO conductive glass with deionized water, acetone, absolute ethanol, and isopropanol for 15 minutes;

[0032] S1.2. Dry the cleaned FTO conductive glass in the air, and then treat it with ultraviolet and ozone for 15 minutes;

[0033] S1.3. Prepare 60 mL of titanium tetrachloride (TiCl 4 ) solution;

[0034] S1.4. The above cleaned FTO conductive glass is put into the prepared titanium tetrachloride solution at about 45°, and hydrolyzed in a constant temperature water bath at 70°C for 1 h, and then rinsed with water and absolute ethanol respectively;

[0035] S1.5. Anneal the FTO conductive glass at 100 °C for 1 h, that is, deposit and form a dense titanium dioxide film on the FTO conductive glass;

[0036] Step S2--Preparation of perovskite film (light absorbing layer):

[0037] S2...

Embodiment 3

[0045] The difference from Example 1 is: the prepared single crystal material is (BEA) 0.5 (CH(NH 2 ) 2 ) 3 Pb 3 I 10 , the corresponding iodide correspondingly replaced by CH(NH 2 ) 2 1, other are all with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com