Anti-reflective electrically-driven 3D liquid crystal lens

A liquid crystal lens and electric drive technology, applied in optics, instruments, nonlinear optics, etc., can solve problems such as interference with the user's viewing of the screen, high reflectivity of the 3D display, and reduced screen contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

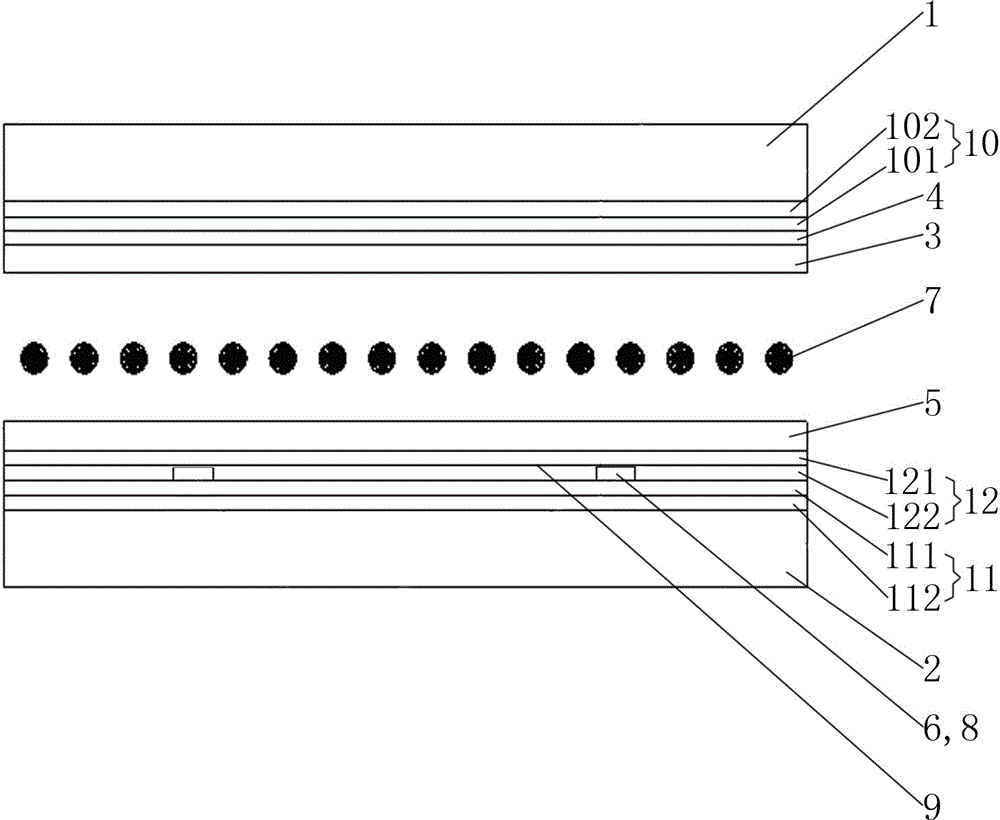

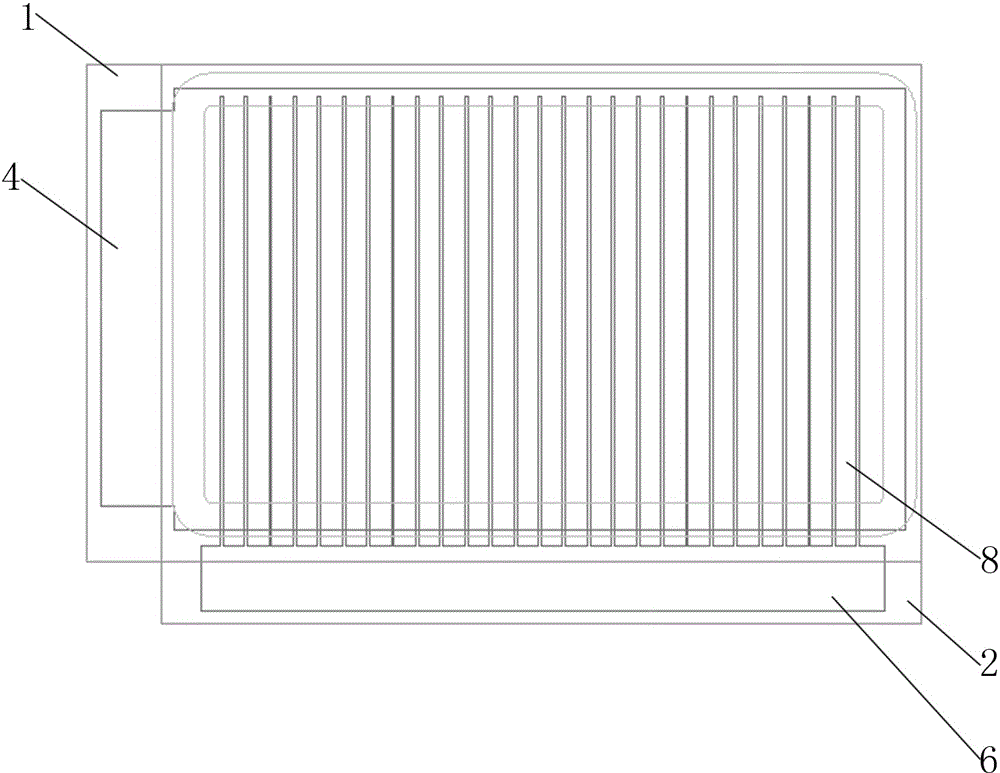

[0022] Such as figure 1 and figure 2 As shown, this anti-reflection electrically driven 3D liquid crystal lens includes a first substrate 1, a second substrate 2, a first alignment layer 3 and a first electrode 4 disposed inside the first substrate 1, and a first electrode 4 disposed inside the second substrate 2. The second alignment layer 5 and the second electrode 6; a liquid crystal layer 7 is arranged between the first substrate 1 and the second substrate 2, and the liquid crystal layer 7 is a nematic liquid crystal; the first electrode 4 and the second electrode 6 are oxide Indium tin film, the first electrode 4 is a continuous electrode on the whole surface, the second electrode 6 is composed of a plurality of linear electrodes 8 arranged side by side, and a gap 9 is provided between two adjacent linear electrodes 8; the first electrode 4 and the second electrode A first anti-reflection layer 10 is provided between the substrates 1. The first anti-reflection layer 10 ...

Embodiment 2

[0028] In the case that other parts are the same as in the first embodiment, the difference is that the first sublayer 101 is a titanium oxide film, and the second sublayer 102 is a silicon oxide film.

Embodiment 3

[0030] When other parts are the same as those in the first or second embodiment, the difference is that the first sublayer 101 is close to the first electrode 4 , and the second sublayer 102 is close to the first substrate 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com