Tool special for wire drawing installation of electric transmission line guyed tower and wire drawing method

A special tool and transmission line technology, which is applied in the field of installation and construction of transmission line towers, can solve the problems such as the inability to take root of the lever hoist when tightening the cable, the small reserved space on the upper part of the pre-embedded hardware, and the inability to install the cable, so as to achieve less mechanical The effect of leasing costs, reducing environmental damage, and reducing engineering construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

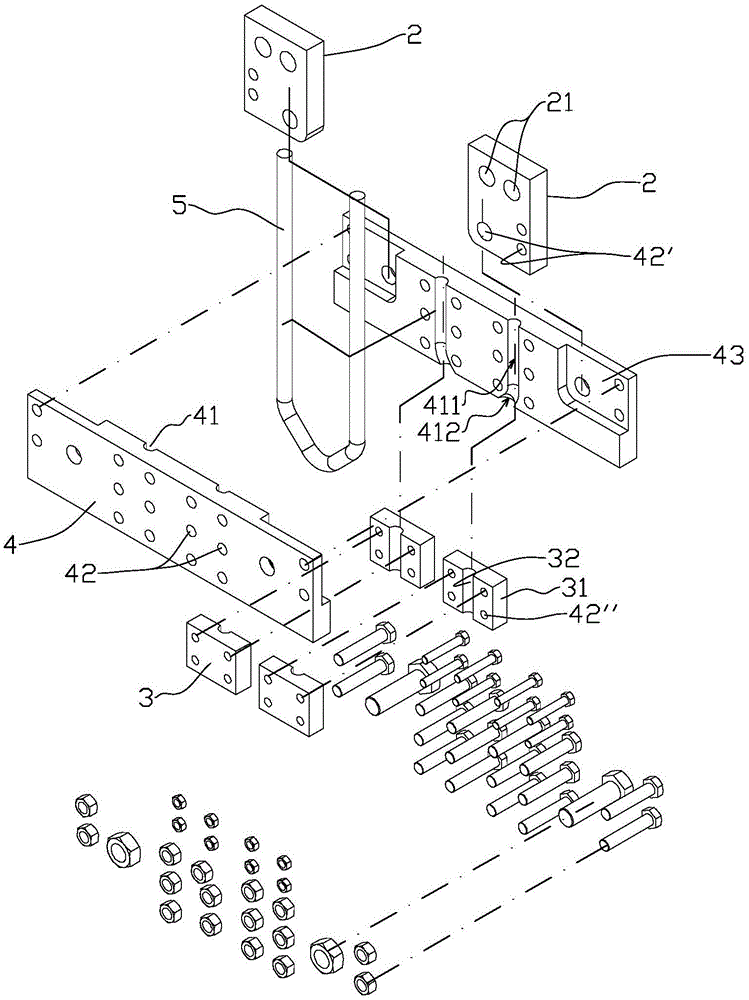

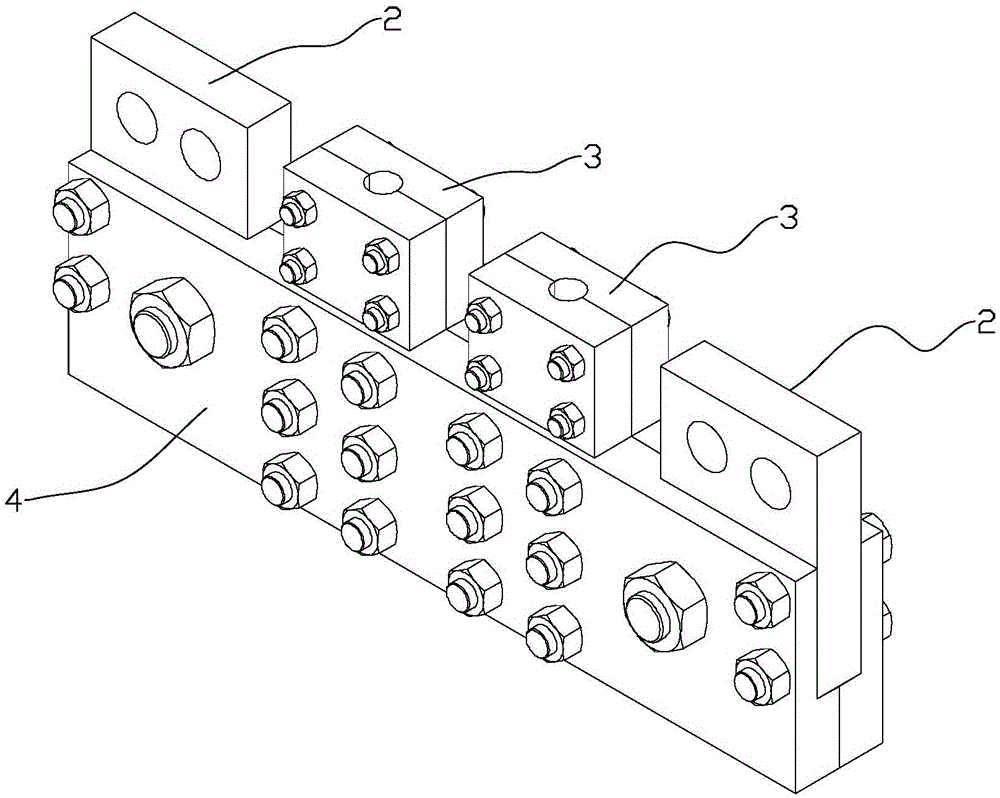

[0042] Such as Figure 1 to Figure 7 As shown, in view of the existing defects, a special tool has been developed-a tool that can be fixed on the pull wire fittings connected to the foundation embedded fittings. The special tool can lead to multiple bolt hanging points for fixing temporary pull wires and tightening the formal Pull the lever hoist.

[0043] The structure of the assembly of the cable fittings and the cable embedded fittings is attached Image 6 . Among them, the bottom structure of the cable fitting 5 is V-shaped, and the upper part is a straight rod part, which is generally a steel part.

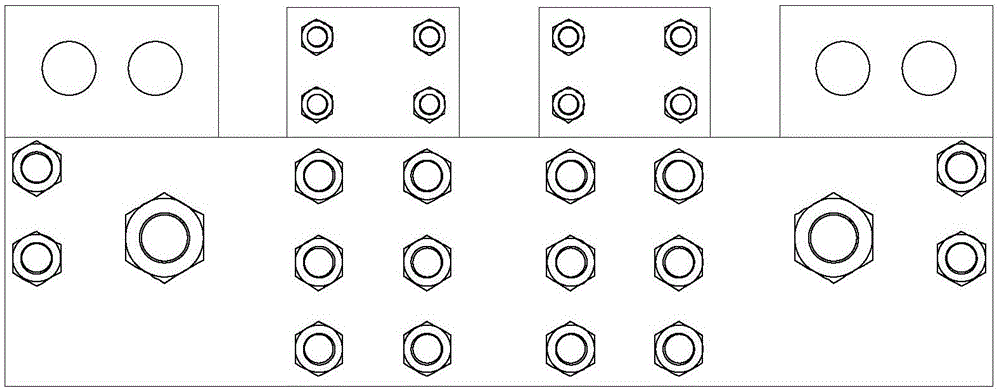

[0044] The tool part includes a splint, an ear plate and a fastener, wherein the splint and the fastener are arranged in pairs. There is one ear plate on the left and right, and the structure is described in detail below.

[0045] For the 4 part of the splint, prepare two rectangular steel plates, and process the channels 41 for installing the cable fittings on the two steel plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com