Novel composite board

A composite panel, a new type of technology, is applied in hull design, hull parts, hull, etc. It can solve the problems of high heat transfer coefficient, easy to be corroded, and poor heat preservation effect, and achieve good strength and mechanical properties, and is not easy to be corroded. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

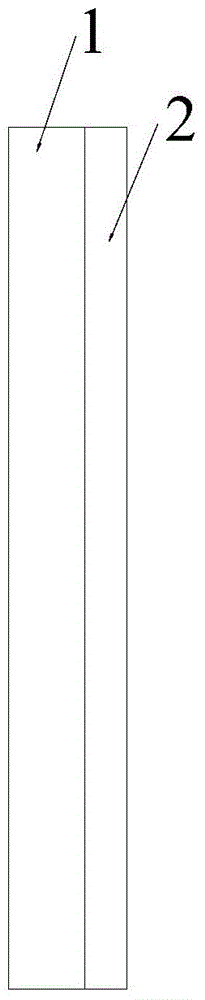

[0025] Such as figure 1 As shown, the new composite panel of this embodiment includes a metal layer 1 and an anti-corrosion and heat-preservation layer 2, and the metal layer 1 is a stainless steel plate. The preparation method of the new composite board is:

[0026] (1) Select a stainless steel plate as the metal layer 1;

[0027] (2) Preparation of anti-corrosion and thermal insulation coating: select raw material epoxy resin, stainless steel powder and glass fiber, wherein glass fiber uses glass fiber powder, and their weight ratio is epoxy resin / stainless steel powder=2:1; epoxy resin and stainless steel powder The total amount / glass fiber=3:1, the epoxy resin is a two-component epoxy resin, and the weight of the epoxy resin is the sum of the weights of the two components. Add stainless steel powder and glass fiber to the epoxy resin, stir, and then add a certain amount of diluent (the diluent is acetone) until the mixture is uniform;

[0028] (3) Grinding and cleaning ...

Embodiment 2

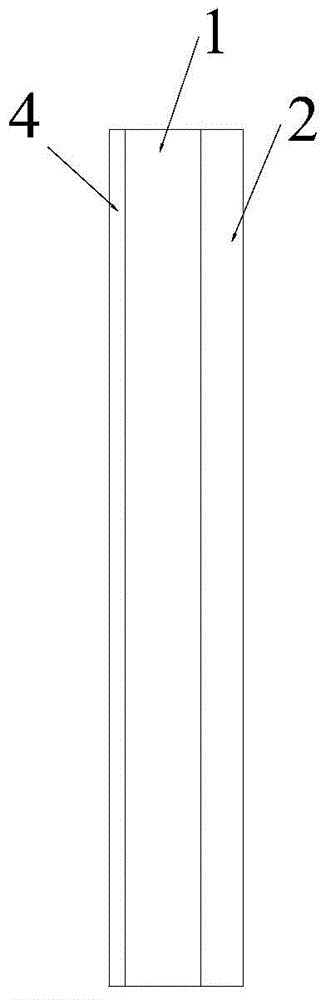

[0031] Such as figure 2 As shown, the novel composite panel of this embodiment includes a metal layer 1, an anti-corrosion insulation layer 2 and an anodized film layer 4, the metal layer 1 is an aluminum alloy plate, the anodized film layer 4 is an anodized aluminum layer, and the anodized aluminum layer The thickness is 10 μm, and the thickness of the anti-corrosion insulation layer 2 is 1 mm. The preparation method of the new composite board is:

[0032] (1) Select an aluminum alloy plate as the metal layer 1;

[0033] (2) Anodize the inner side of the aluminum alloy plate to form a 10 μm anodized aluminum layer;

[0034] (3) Preparation of anti-corrosion and thermal insulation coatings: select raw materials phenolic resin, aluminum alloy powder and glass fiber, among which glass fiber is selected from glass fiber filaments, and their weight ratio is phenolic resin / aluminum alloy powder = 1:1; phenolic resin and aluminum alloy powder The total amount / glass fiber=9:2, th...

Embodiment 3

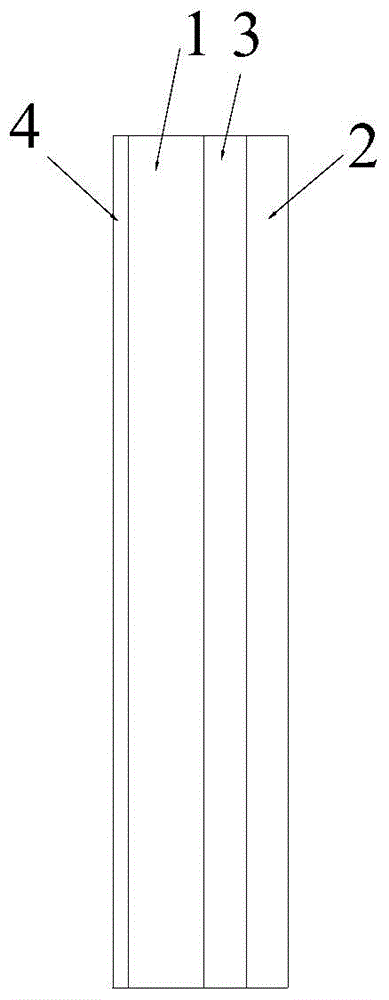

[0038] Such as image 3 As shown, the novel composite panel of this embodiment includes a metal layer 1, a buffer layer 3, an anti-corrosion insulation layer 2 and an anodized film layer 4, the metal layer 1 is an aluminum alloy plate, the anodized film layer 4 is an anodized aluminum layer, and the buffer layer Layer 3 is cured by the buffer coating, the thickness of the anodized aluminum layer is 15μm, and the thickness of the anti-corrosion insulation layer is 3mm. The preparation method of the new composite board is:

[0039] (1) Select an aluminum alloy plate as the metal layer 1;

[0040] (2) Anodizing treatment is carried out on the inner side of the aluminum alloy plate to form a 15 μm anodized aluminum layer;

[0041] (3) Preparation of buffer coating: select unsaturated polyester resin and aluminum alloy powder as raw materials, and the weight ratio unsaturated polyester resin / aluminum alloy powder = 1:2; add aluminum alloy powder to unsaturated polyester resin, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com