Metal bipolar plate and preparation method thereof and fuel cell

A metal bipolar plate and metal substrate technology, which is used in fuel cells, fuel cell parts, metal material coating processes, etc., can solve the problem of limited pore sealing ability in corrosion-resistant coatings, slow film deposition speed, and coating time. Long and other problems, to achieve the effect of excellent corrosion resistance and electrical conductivity, prevent oxidation, and improve the coating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

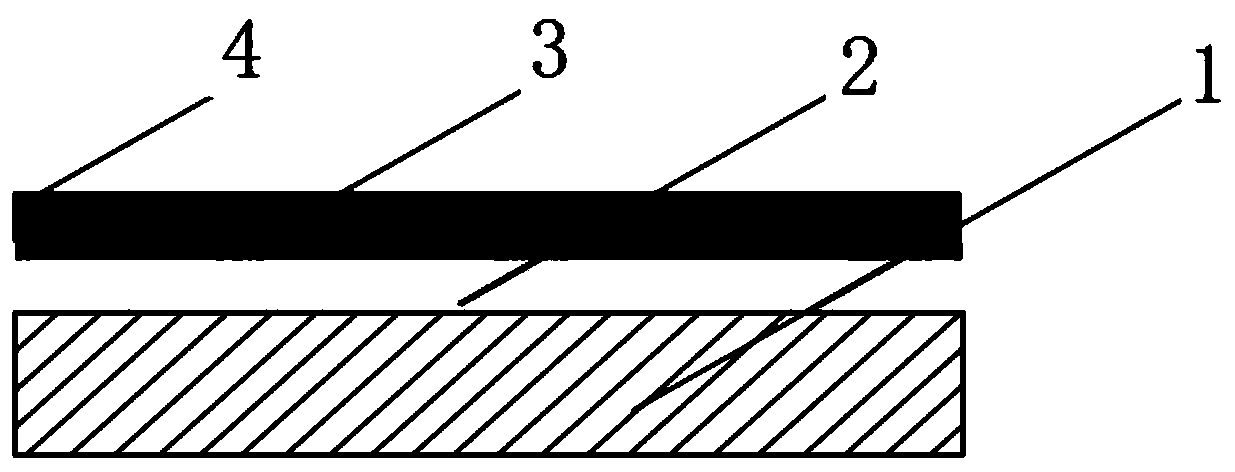

Image

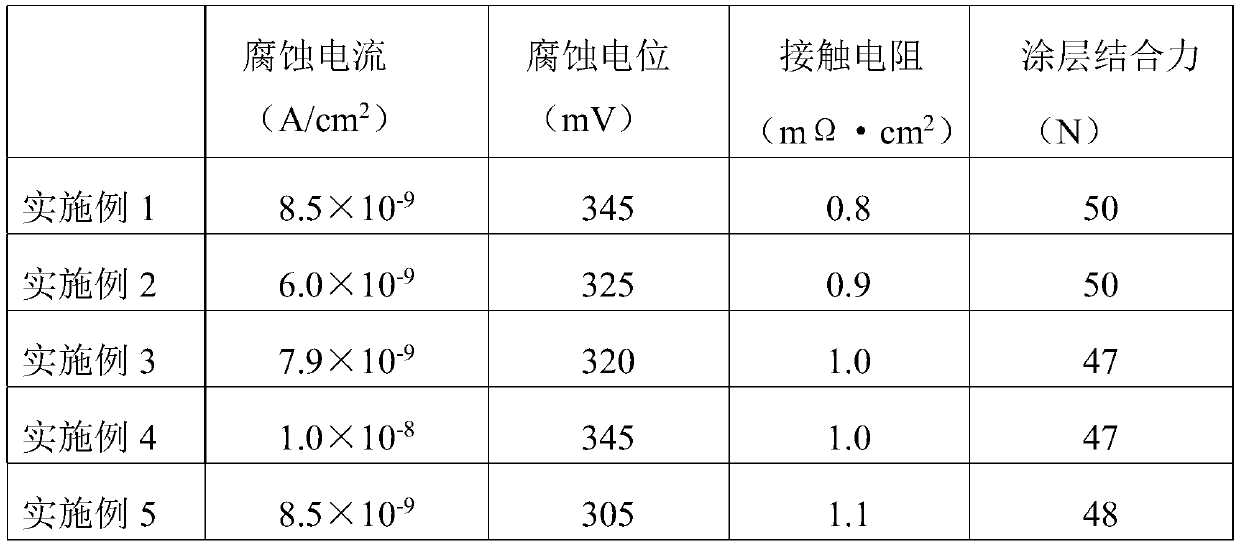

Examples

preparation example Construction

[0063] On the other hand, the embodiment of the present invention also provides a method for preparing a metal bipolar plate, which specifically includes the following steps:

[0064] 1. Pretreatment: Perform pretreatment operations on the metal substrate to improve the cleanliness and surface roughness of the metal substrate. This step specifically includes:

[0065] 11) The first pretreatment: degreasing, polishing, cleaning, and drying treatments are performed on the metal substrate in sequence. Specifically, the selected metal substrate is subjected to the first degreasing treatment with 1M sodium hydroxide solution at high temperature (80° C.); after cleaning, the second degreasing cleaning is performed with alcohol. Then, polish the substrate with brighteners such as alumina polishing paste or diamond polishing paste. On the one hand, the oxide scale on the surface is taken out, and on the other hand, the surface texture and defects are reduced by polishing treatment to impr...

Embodiment 1

[0079] 316L stainless steel is selected as the metal substrate of this embodiment. The steps of depositing a coating on the metal substrate to prepare a metal bipolar plate are as follows:

[0080] 1) Degreasing, polishing, cleaning, and drying treatments are performed on the metal substrate in sequence.

[0081] Specifically, the selected metal substrate is subjected to the first degreasing treatment with 1M sodium hydroxide solution at high temperature (80° C.); after cleaning, the second degreasing cleaning is performed with alcohol. Then, the substrate is polished with a brightener such as diamond polishing paste. On the one hand, the oxide scale on the surface is taken out, and on the other hand, the surface texture and defects are reduced by polishing, and the flatness of the material is improved. After polishing, clean it with pure water, and put the cleaned metal substrate in pure water for storage, and purge it with clean nitrogen before use.

[0082] 2) Using bias magnetr...

Embodiment 2

[0088] 316L stainless steel is selected as the metal substrate of this embodiment. The steps of depositing a coating on the metal substrate to prepare a metal bipolar plate are as follows:

[0089] 1) Degreasing, polishing, cleaning, and drying treatments are sequentially performed on the metal substrate.

[0090] Specifically, the selected metal substrate is subjected to a first degreasing treatment at a high temperature (80° C.) with a 1M sodium hydroxide solution; after cleaning, the second degreasing cleaning is performed with alcohol. Then, polish the substrate with a brightener such as alumina polishing paste. On the one hand, the oxide scale on the surface is taken out, and on the other hand, the surface texture and defects are reduced by polishing treatment, and the flatness of the material is improved. After polishing, clean it with pure water, and put the cleaned metal substrate in pure water for storage, and purge it with clean nitrogen before use.

[0091] 2) Using bias...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com