Vibration diaphragm and miniature sounder with the vibration diaphragm

A film layer and vibration system technology, applied in the direction of planar diaphragm, sensor, loudspeaker, etc., can solve problems such as cracking, shortening the service life of micro-speakers, and reducing the reliability of micro-speakers, so as to achieve long service life and improve Reliability and stability, enhanced stretch and elastic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

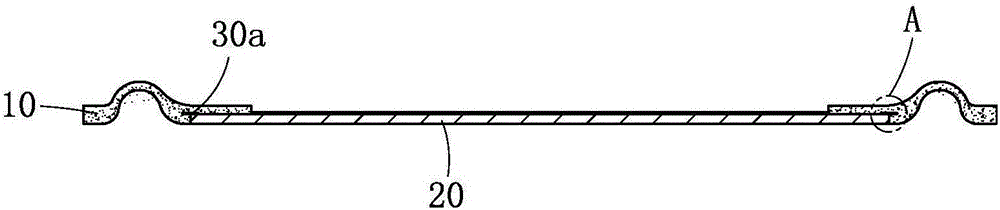

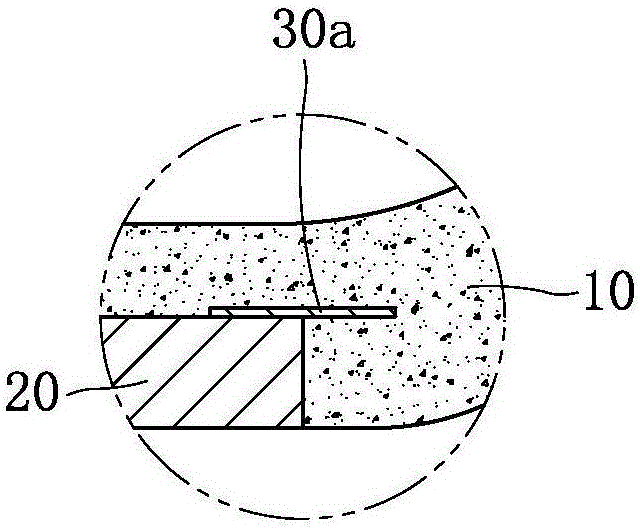

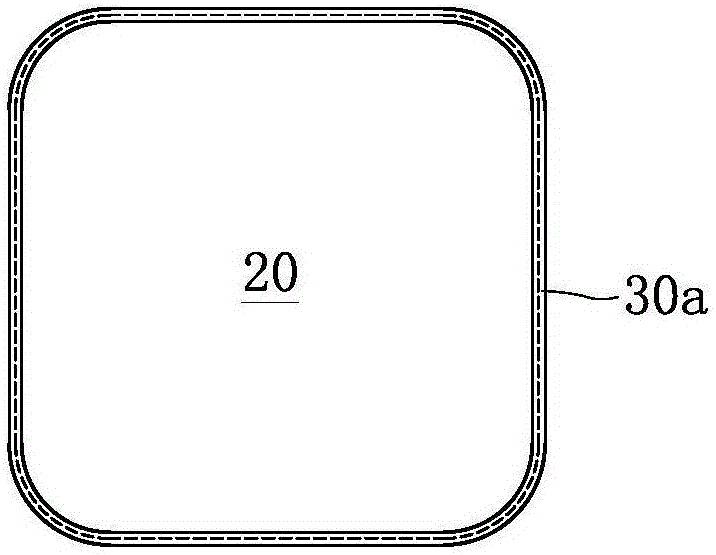

[0035] Such as figure 1 and figure 2 Commonly shown, a diaphragm, together with the voice coil constitutes the vibration system of the miniature sounder. Including the diaphragm body part 10 and the diaphragm center part 20 combined together, the diaphragm center part 20 is combined in the central position of the diaphragm body part 10 as an insert. In this embodiment, the diaphragm body part 10 and the diaphragm center part 20 combined by injection molding process. The part of the diaphragm center part 20 in the thickness direction is wrapped in the diaphragm body part 10. In this embodiment, the upper end surface of the edge part of the diaphragm center part 20 is wrapped in the diaphragm body part 10, that is, the diaphragm center part 20 The upper surface of the diaphragm body part 10 is wrapped, and the lower surface of the diaphragm center part 20 is exposed outside the diaphragm body part 10 . The upper end surface of the edge portion of the diaphragm center part 20...

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, the difference is that:

[0040] The reinforcing piece is a discontinuous segmented structure distributed along the edge of the center of the diaphragm.

[0041] Such as Figure 4 As shown, in this embodiment, the reinforcement 30 b is an arc structure, and there are four sections in total, and the four reinforcements 30 b are respectively located at the four corners of the diaphragm central portion 20 .

[0042]Such as Figure 5 As shown, the reinforcing piece 30c is a straight line structure, and there are four sections in total, and the four sections of the reinforcing piece 30c are respectively located at the four straight sides of the diaphragm center portion 20 .

[0043] The embodiment in which the reinforcement is a discontinuous segmental structure is not limited to the above two, and can also be distributed at the corner position and the straight edge position of the center of the diaphragm at the same t...

Embodiment 3

[0045] This embodiment is basically the same as Embodiment 1 or Embodiment 2, the difference is:

[0046] Such as Figure 6 As shown, the diaphragm center part 20 is wrapped in the diaphragm body part 10 as a whole, that is, the upper and lower end surfaces of the edge part of the diaphragm center part 20 are wrapped in the diaphragm body part, and the reinforcement part 30a is fixed on on one of the end surfaces.

[0047] In practical applications, reinforcing pieces can also be fixed on both the upper and lower end surfaces of the edge portion of the central part of the diaphragm, and the effect of fixing the reinforcing pieces on both end surfaces is better in preventing the diaphragm from cracking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com