Thermal control system and method

a technology of temperature control and system, applied in the direction of fluid circulation arrangement, refrigeration machines, lighting and heating apparatus, etc., can solve the problems of unstable loop gain of servo system, time delay in cooling load, etc., to reduce the amount of cooling available, shorten response time, and improve the effect of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

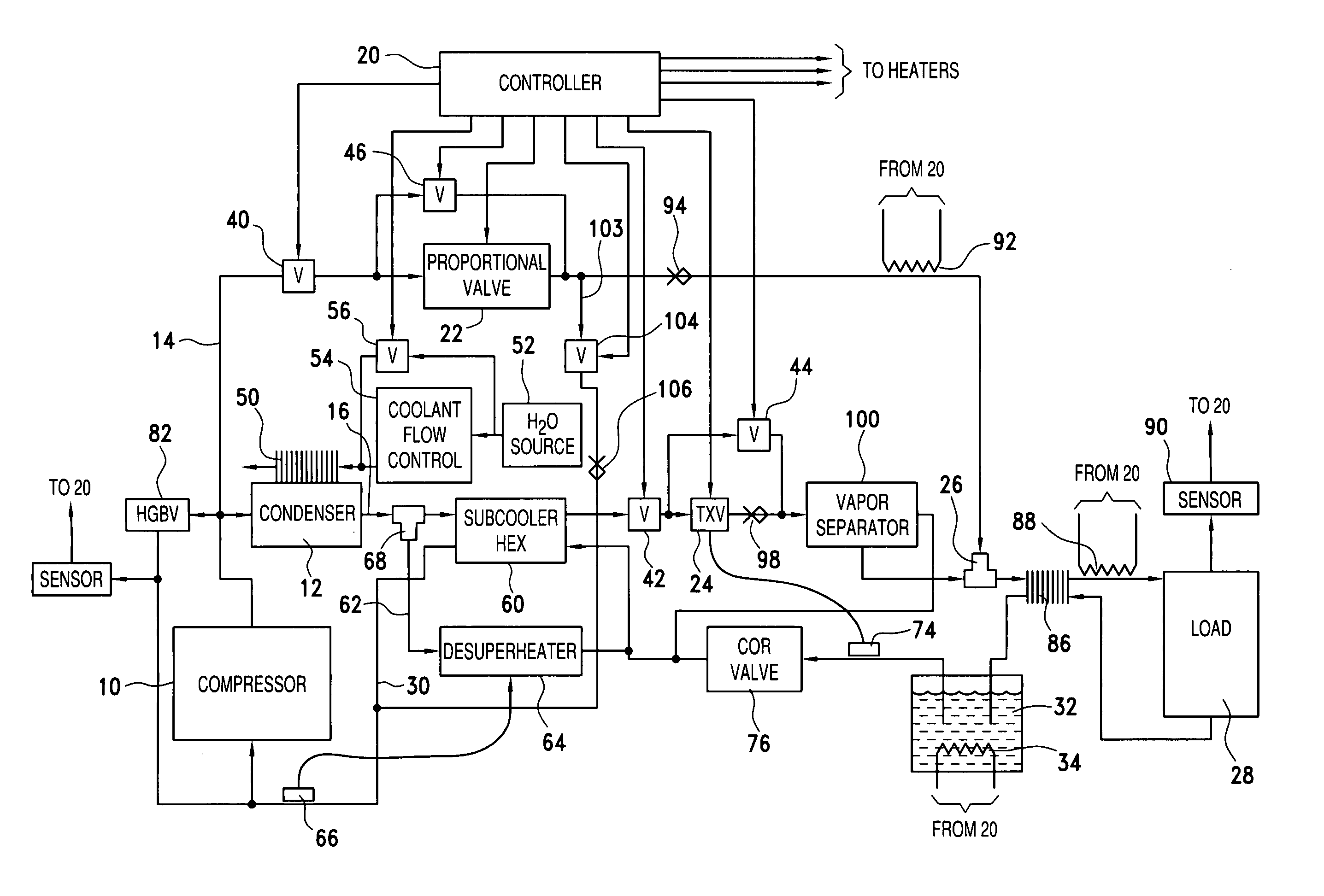

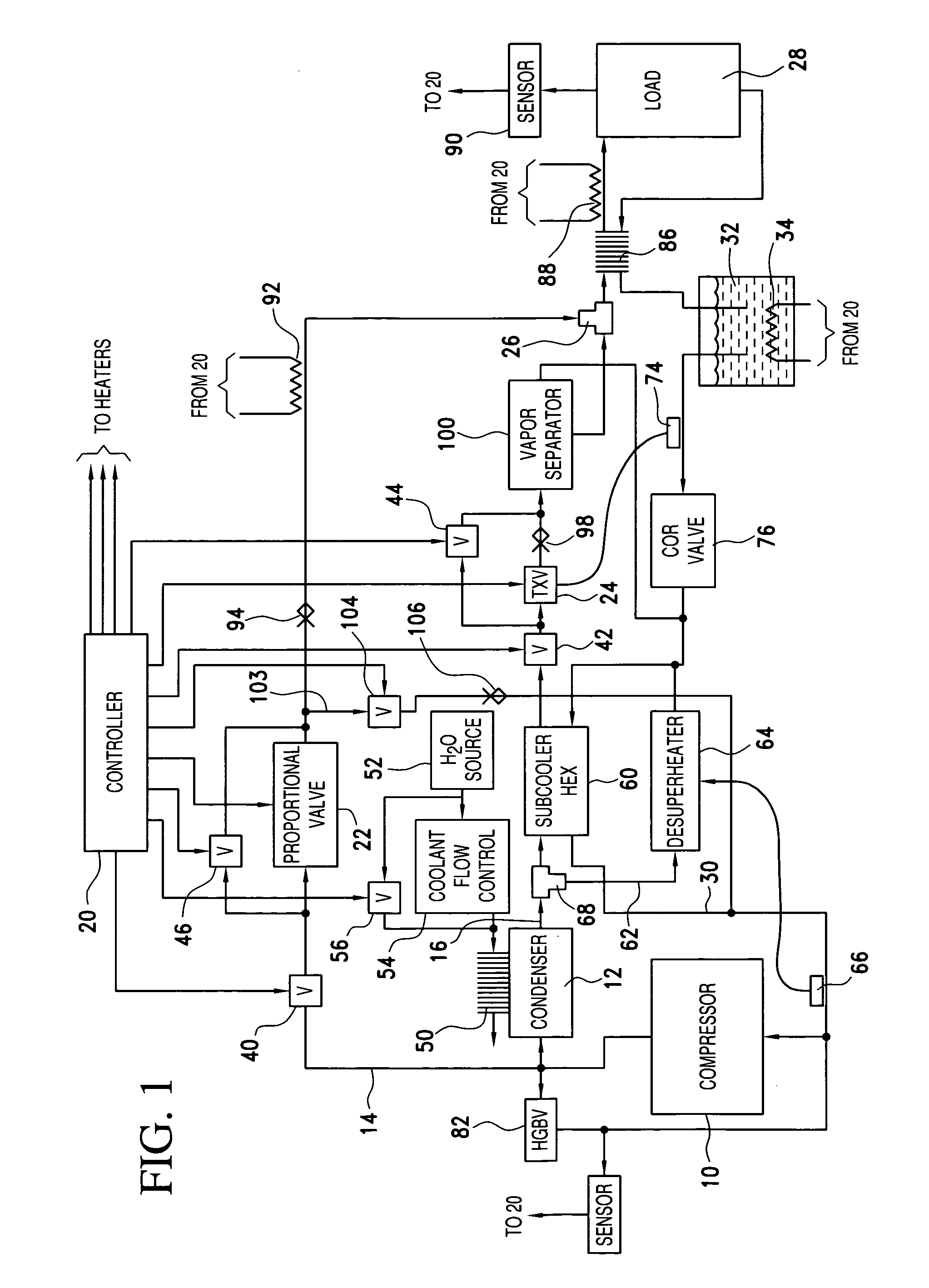

[0014] Referring now specifically to FIG. 1, a temperature control system is shown utilizing a novel refrigeration / heating cycle in accordance with the above-referenced previously filed Cowans et al application Ser. No. 11 / 057,383. The present system integrally incorporates features in this context for achieving improved stability and / or efficiency when directly transferring thermal energy using saturated fluids.

[0015] In FIG. 1, a compressor 10, which may use a conventional refrigerant such as R507, or a different refrigerant depending upon the application, feeds compressed hot gas into a condenser 12 which also is arranged as part of a pressure regulating system. The compressor 10 output is fed into a hot gas line 14 which is separately split to a condensed refrigerant line 16, the flow proportions being controlled by a digital controller system 20, as described in the previously filed application. The hot gas line 14 includes a proportional valve 22 operated by the controller 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com