Thermal control loop heat pipe of integrated structure

A loop heat pipe and structural heat technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of insufficient heat transfer capacity of heat pipes, weak structural adaptability design ability, and poor system temperature uniformity. To achieve the effect of improving the resistance to mechanical adaptability, increasing the scope of application, and ensuring heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

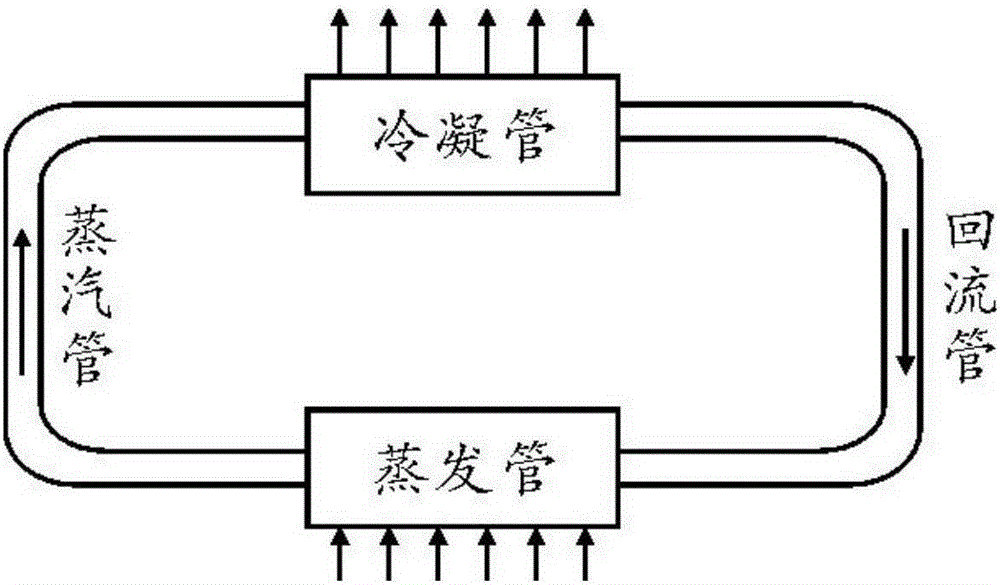

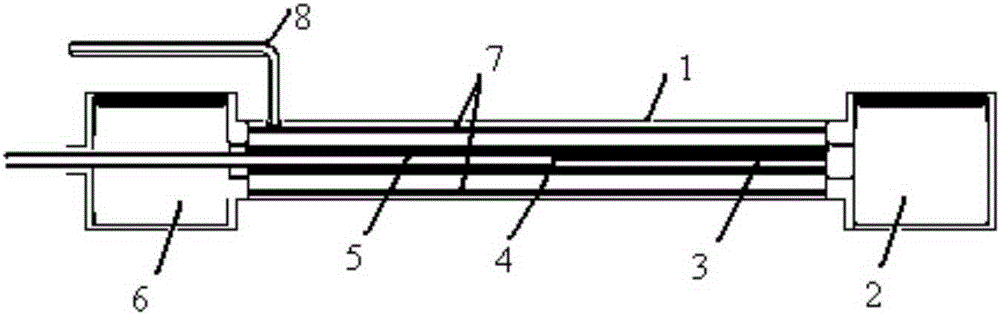

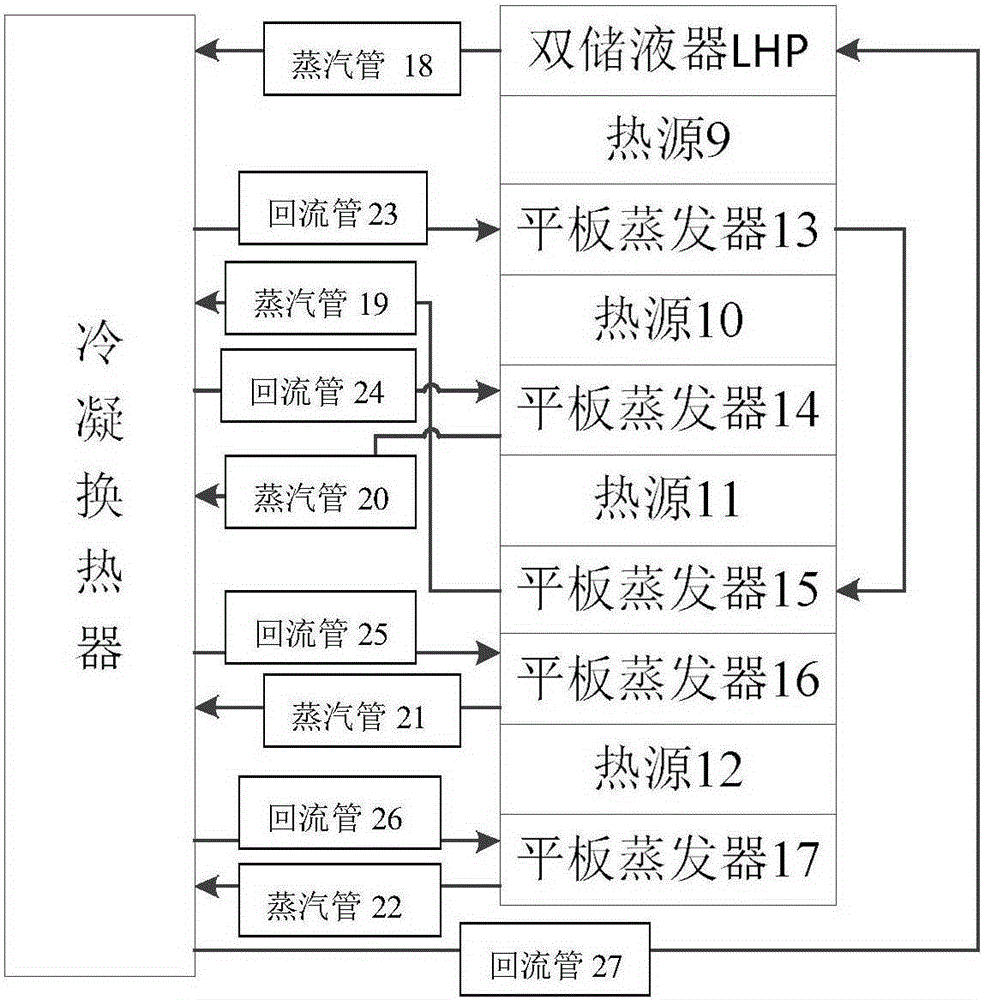

[0018] refer to figure 1 . In one of the best embodiments described below, the heat pipe with integrated structural thermal control loop includes a structural thermal control integrated hollow metal tube body filled with phase change medium in the tube, wherein: the structural thermal control hollow metal tube is formed by the condensation tube The loop heat pipe LHP formed in series with the evaporator, the two sides of the evaporator are connected to the liquid reservoir through the steam pipe and the return pipe, and the liquid reservoirs on both sides are filled with liquid working fluid; the heat emitted by the heat source is absorbed by the evaporation pipe Finally, the liquid working medium undergoes a phase change, and the liquid working medium enters the condensing pipe through the steam pipe to release heat and condenses, and then flows back to the evaporating pipe through the return pipe to complete a complete loop heat pipe cycle. A semiconductor cooler (TEC) is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com