A manufacturing process of washing-resistant high-brightness color reflective products

A manufacturing process and washing-resistant technology, which is applied in metal material coating technology, optics, optical components, etc., can solve the problems of low production efficiency and poor washing resistance, and achieve improved service life, improved uniformity, and excellent coating effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

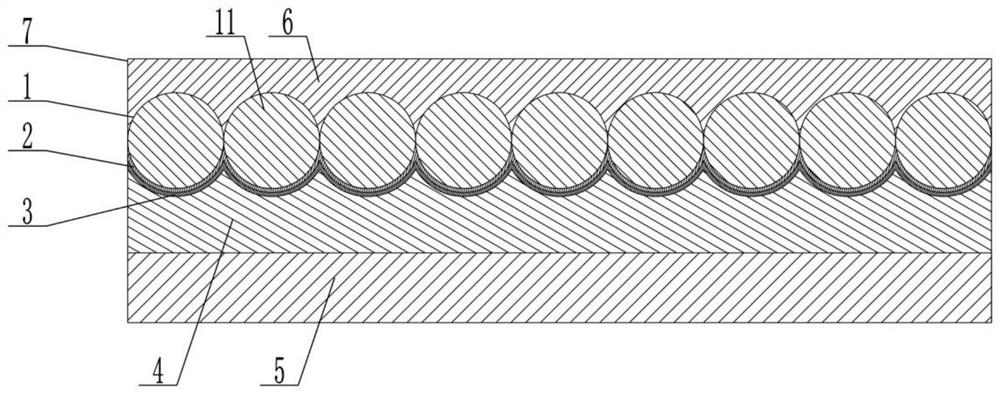

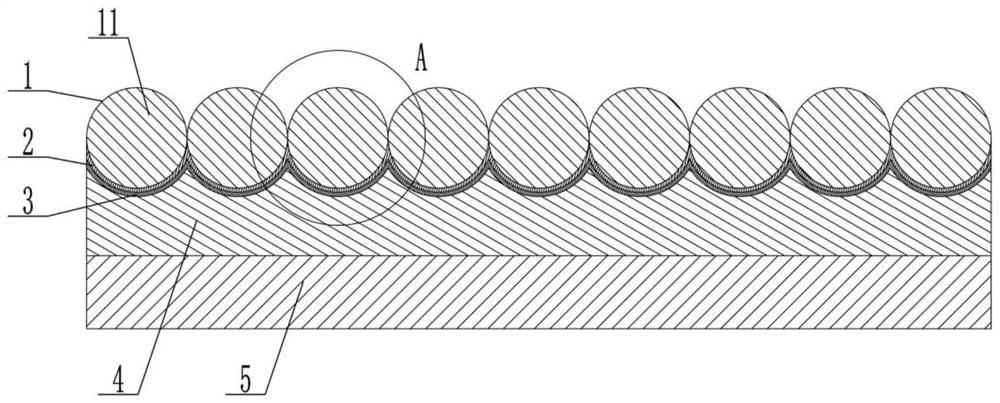

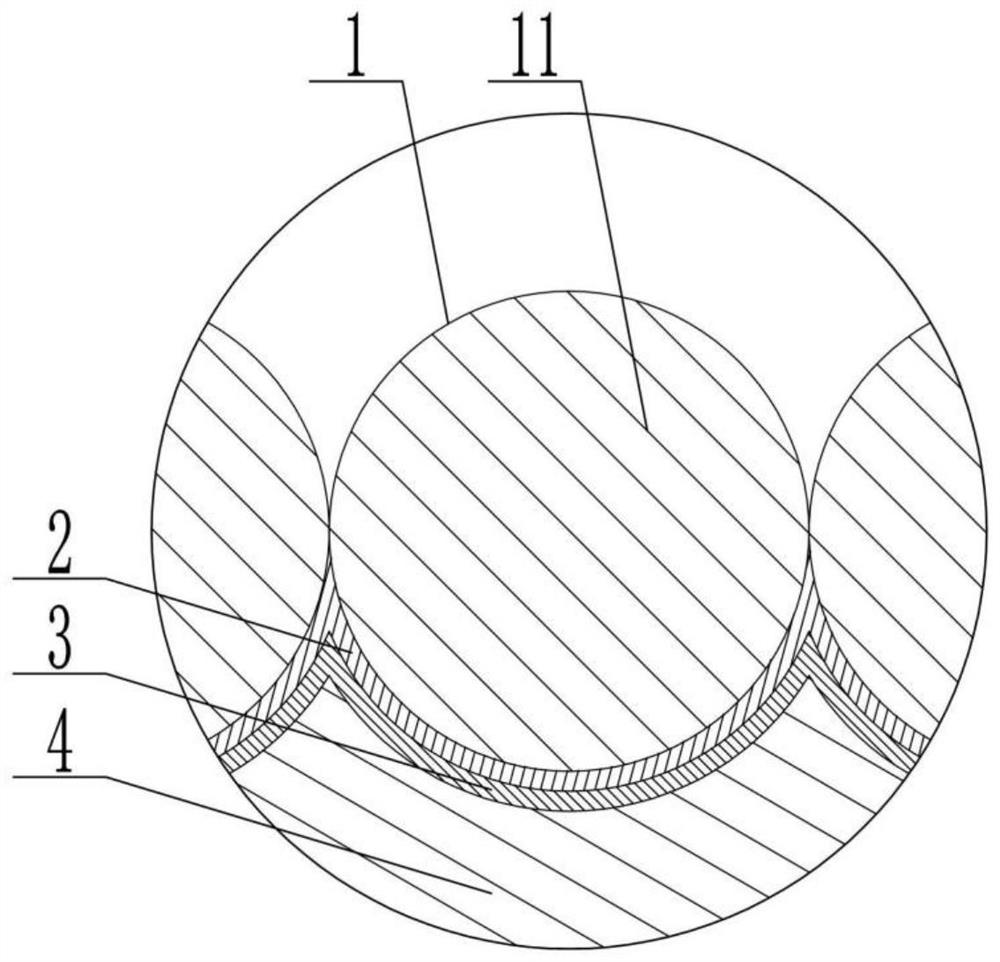

[0053] A manufacturing process of washing-resistant high-brightness colored reflective products, comprising a glass bead layer 1, a colored resin layer 2, a reflective layer 3, an adhesive layer 4, and a substrate layer 5, and the thickness of the adhesive layer 4 is 30 μm, the thickness of the colored resin layer 2 is 2 μm, the thickness of the reflective layer 3 is 15nm, and the manufacturing steps are as follows:

[0054] (a) Take the carrier 6 and the glass beads 11 and place them in the bead-planting equipment, and apply glue or heat to evenly arrange the glass beads 11 on the surface of the carrier 6 to form the bead-planting film 7. The glass beads 11 Arranged in a single layer and the particle size error is within 10 μm;

[0055] (b) Add solid hard saturated polyester and unsaturated polyester soft resin into the reaction kettle as the main resin, wherein the glass transition temperature Tg of the solid hard saturated polyester is 40°C, the molecular weight is 20000, a...

Embodiment 2

[0072] A manufacturing process of washing-resistant high-brightness colored reflective products, comprising a glass bead layer 1, a colored resin layer 2, a reflective layer 3, an adhesive layer 4, and a substrate layer 5, and the thickness of the adhesive layer 4 is 120 μm, the thickness of the colored resin layer 2 is 10 μm, the thickness of the reflective layer 3 is 40nm, and the manufacturing steps are as follows:

[0073] (a) Take the carrier 6 and the glass beads 11 and place them in the bead-planting equipment, and apply glue or heat to evenly arrange the glass beads 11 on the surface of the carrier 6 to form the bead-planting film 7. The glass beads 11 Arranged in a single layer and the particle size error is within 10 μm;

[0074] (b) Add solid hard saturated polyester and unsaturated polyester soft resin into the reaction kettle as the main resin, wherein the glass transition temperature Tg of the solid hard saturated polyester is 80°C, the molecular weight is 60000,...

Embodiment 3

[0091] A manufacturing process of washing-resistant high-brightness colored reflective products, comprising a glass bead layer 1, a colored resin layer 2, a reflective layer 3, an adhesive layer 4, and a substrate layer 5, and the thickness of the adhesive layer 4 is 50 μm, the thickness of the colored resin layer 2 is 6 μm, the thickness of the reflective layer 3 is 27nm, and the manufacturing steps are as follows:

[0092] (a) Take the carrier 6 and the glass beads 11 and place them in the bead-planting equipment, and apply glue or heat to evenly arrange the glass beads 11 on the surface of the carrier 6 to form the bead-planting film 7. The glass beads 11 Arranged in a single layer and the particle size error is within 10 μm;

[0093] (b) Add solid hard saturated polyester and unsaturated polyester soft resin into the reaction kettle as the main resin, wherein the glass transition temperature Tg of the solid hard saturated polyester is 60°C, the molecular weight is 40000, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com