Environment-friendly two-component marking coating as well as preparation method, use method and application thereof

A marking paint, two-component technology, applied in the field of environment-friendly two-component marking paint and its preparation, can solve the problems of poor recoatability, low construction efficiency, VOC volatilization, etc., and achieve improved retroreflective performance, the best Use effect, effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

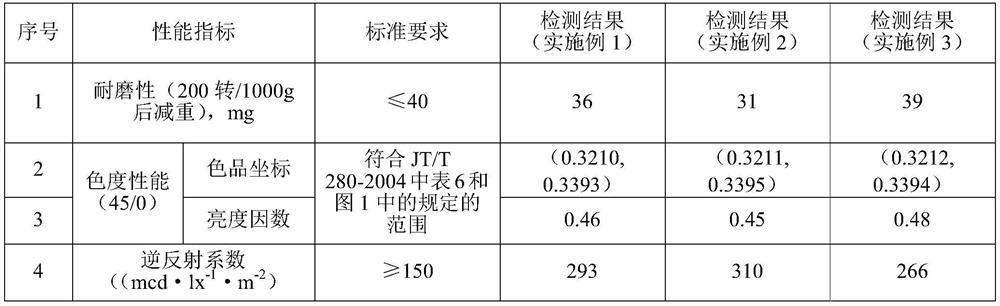

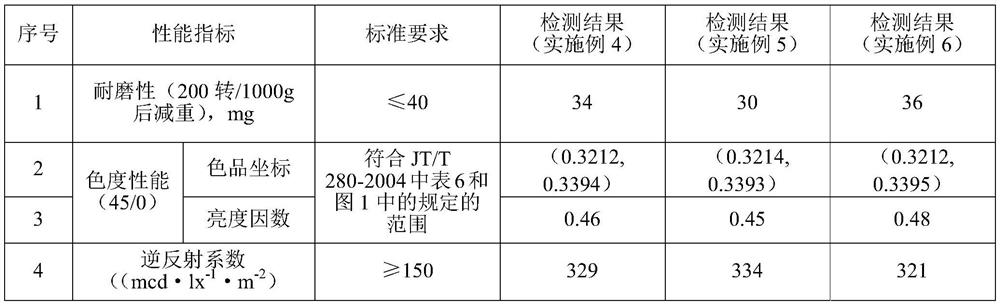

Examples

Embodiment 1

[0044] (1), preparation of modified glass beads:

[0045] a. prepare 2% SDBS solution;

[0046] b. adding glass beads with a particle diameter of 0.5 mm into the SDBS solution obtained in step (1), stirring magnetically for 60 minutes at a constant temperature of 50° C., taking out the glass beads, and standing for 30 minutes at room temperature, the obtained glass beads were placed Dry in a vacuum box to obtain glass beads coated with SDBS film.

[0047] (2) Preparation of environment-friendly two-component marking paint:

[0048] a. Component A: Weigh 50g 655 resin, 0.2g rheological agent-2, 0.3g dispersant, 0.13g rheological agent-1 according to the formula, stir at 300-500r / min for 5min until evenly mixed, then add 47.6 g titanium dioxide and 54.3g calcium carbonate, keep the speed constant, add the pigments and fillers to the resin while stirring, and stir at a speed of 400-500r / min for 10 minutes until uniform.

[0049] b. Component B: Weigh 50g of 659 resin, 0.2g of ...

Embodiment 2

[0055] (1), preparation of modified glass beads:

[0056] a. prepare 2% SDBS solution;

[0057] b. adding glass beads with a particle diameter of 0.65 mm into the SDBS solution obtained in step (1), stirring magnetically for 60 minutes at a constant temperature of 50° C., taking out the glass beads, and leaving them to stand at room temperature for 30 minutes. Dry in a vacuum box to obtain glass beads coated with SDBS film.

[0058] (2) Preparation of environment-friendly two-component marking paint:

[0059] a. Component A: Weigh 50g 655 resin, 0.2g rheological agent-2, 0.3g dispersant, 0.13g rheological agent-1 according to the formula, stir at 300-500r / min for 5min until evenly mixed, then add 47.6 g titanium dioxide and 54.3g calcium carbonate, keep the speed constant, add the pigments and fillers to the resin while stirring, and stir at a speed of 400-500r / min for 10 until uniform.

[0060] b. Component B: Weigh 50g of 659 resin, 0.2g of rheological agent-2, 0.3g of di...

Embodiment 3

[0066] (1), preparation of modified glass beads:

[0067] a. prepare 2% SDBS solution;

[0068] b. adding glass beads with a particle diameter of 0.7 mm into the SDBS solution obtained in step (1), stirring magnetically for 60 minutes at a constant temperature of 50° C., taking out the glass beads, and leaving them to stand at room temperature for 30 minutes. Dry in a vacuum box to obtain glass beads coated with SDBS film.

[0069] (2) Preparation of environment-friendly two-component marking paint:

[0070] a. Component A: Weigh 50g 655 resin, 0.2g rheological agent-2, 0.3g dispersant, 0.13g rheological agent-1 according to the formula, stir at 300-500r / min for 5min until evenly mixed, then add 47.6 g titanium dioxide and 54.3g calcium carbonate, keep the speed constant, add the pigments and fillers to the resin while stirring, and stir at a speed of 400-500r / min for 10 until uniform.

[0071] b. Component B: Weigh 50g of 659 resin, 0.2g of rheological agent-2, 0.3g of dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com