Automotive wire harness cloth-based adhesive tape manufactured with UV-curable hot-melt pressure-sensitive adhesive, and manufacturing technology thereof

A technology of hot-melt pressure-sensitive adhesive and curing heat, which is applied in the field of non-woven fabric-based adhesive tape and its manufacture, and polyester cloth-based adhesive tape, which can solve the problems of insufficient temperature resistance and achieve excellent wear resistance and easy operation The effect of simple process and excellent temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

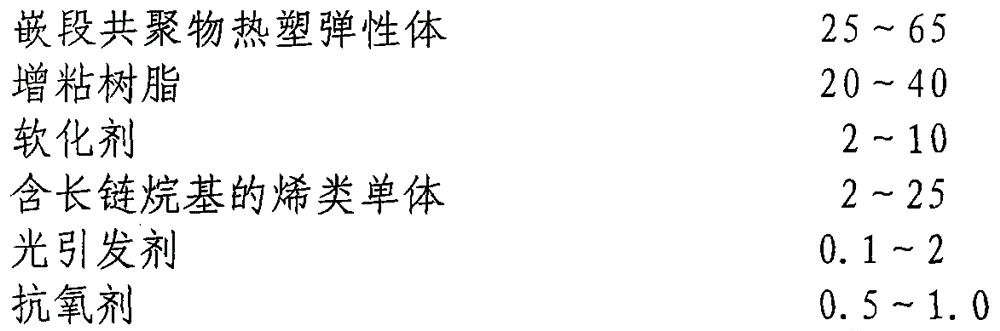

Method used

Image

Examples

Embodiment 1

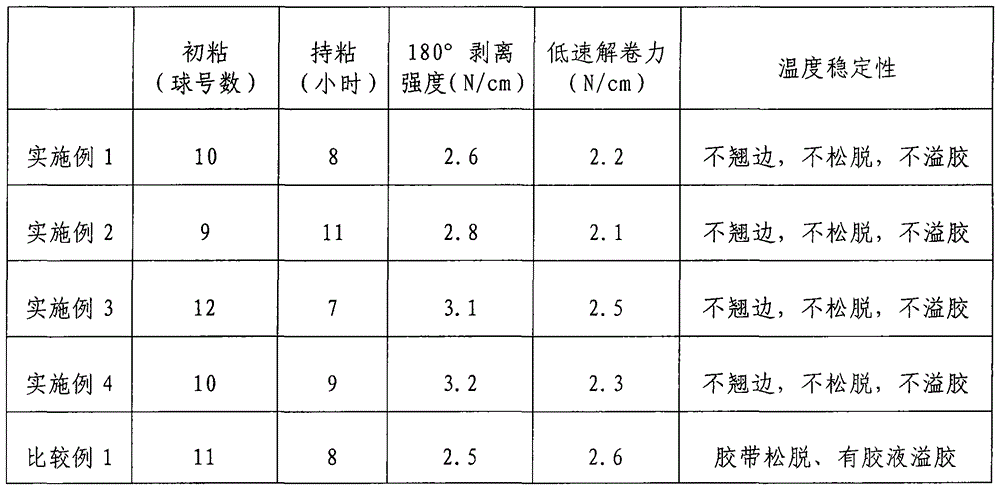

[0029] Embodiment 1: The making process of UV curable hot-melt pressure-sensitive adhesive: 35 parts by weight of block copolymer thermoplastic elastomer SBS, 10 parts by weight of block copolymer thermoplastic elastomer SEBS, softener naphthenic oil 5 Parts by weight, 3 parts by weight of dioctyl phthalate (DOP), 0.8 parts by weight of antioxidant 1010, first add it to the melt tank, protect it with nitrogen for 5 minutes, start stirring and heat it, when the temperature reaches 160-170 After ℃, keep it for 50-60 minutes to completely melt the thermoplastic elastomer, then add 25 parts by weight of petroleum resin, 20 parts by weight of diallyl phthalate, and 1.2 parts by weight of photoinitiator 1173, stop heating, and stir After 20-30 minutes, cool naturally to about 120°C, then discharge and divide into equipment for use.

[0030] Manufacturing process of the cloth-based adhesive tape: the manufacturing of the cloth-based pressure-sensitive adhesive tape can be carried out...

Embodiment 2

[0031]Embodiment 2: The production process of UV curing hot-melt pressure-sensitive adhesive: According to the formula, 35 parts by weight of block copolymer thermoplastic elastomer SIS, 13 parts by weight of block copolymer thermoplastic elastomer SBS, softener naphthenic oil 5 Parts by weight, 3 parts by weight of dioctyl phthalate (DOP), 0.8 parts by weight of antioxidant 1010, first add it to the melt tank, protect it with nitrogen for 5 minutes, start stirring and heat it, when the temperature reaches 160-170 After ℃, keep it for 50-60 minutes to make the thermoplastic elastomer heat-melt completely, then add 30 parts by weight of rosin resin, 12 parts by weight of bis(2-ethylhexyl) maleate, 1.2 parts by weight of photoinitiator 1173 portion, stop heating, stir for 20-30 minutes, cool naturally to about 120°C, then discharge and distribute for equipment.

[0032] The manufacturing process of the cloth-based adhesive tape is the same as in Example 1. The test results are ...

Embodiment 3

[0033] Embodiment 3: The production process of UV curing hot-melt pressure-sensitive adhesive: According to the formula, 35 parts by weight of block copolymer thermoplastic elastomer SIS, 7 parts by weight of block copolymer thermoplastic elastomer SEBS, softener naphthenic oil 5 parts Parts by weight, 1 part by weight of dioctyl phthalate (DOP), 0.8 parts by weight of antioxidant 1010, first add it to the melt tank, protect it with nitrogen for 5 minutes, start stirring and heat it, when the temperature reaches 160-170 After ℃, keep it for 50-60 minutes to completely melt the thermoplastic elastomer, then add 35 parts by weight of hydrogenated rosin resin, 10 parts by weight of di-n-butyl maleate, and 5 parts by weight of 2-ethylhexyl acrylate 11731.2 parts by weight of photoinitiator, stop heating, stir for 20-30 minutes, cool naturally to about 120°C, then discharge and distribute for use.

[0034] The manufacturing process of the cloth-based adhesive tape is the same as in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com