Continuous production process and application of aerogel felt composite material

A technology of composite materials and airgel felt, which is applied in the continuous production process and application field of airgel felt composite materials, can solve the problems of storage and transportation, construction and installation not being convenient enough, unfavorable for large-scale production, and poor mechanical properties of materials, etc. Achieve the effects of enhancing adhesion and mechanical properties, improving comprehensive mechanical properties, and shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

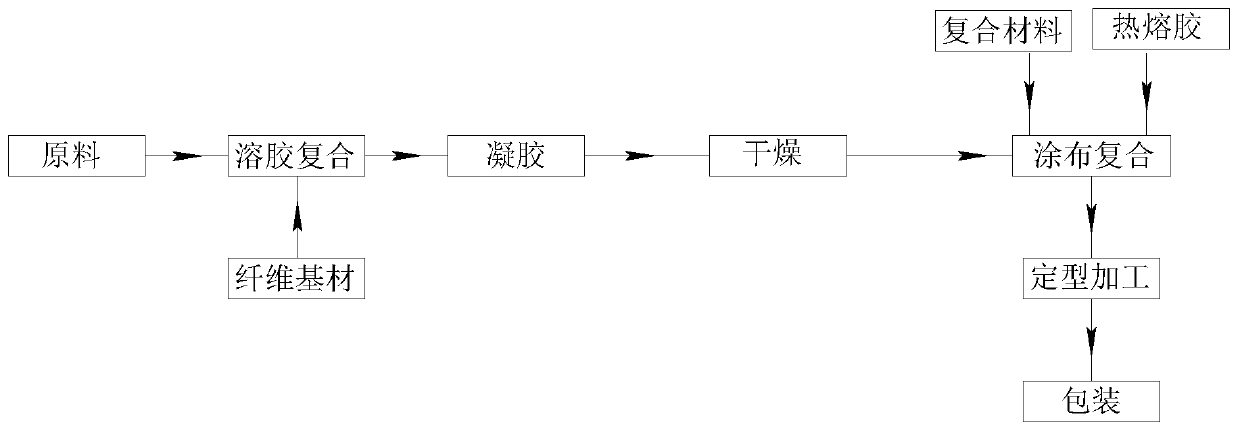

Method used

Image

Examples

Embodiment 1

[0024] Fabricate airgel composites as follows:

[0025] (1) The following raw materials are weighed by weight: 500 parts of sol, 300 parts of hot melt adhesive, 200 parts of composite material and 1000 parts of fiber substrate, and these raw materials are continuously mixed for sol compounding;

[0026] The sol is composed of silicon dioxide, aluminum oxide, zirconium oxide, titanium oxide, iron oxide, zinc oxide, magnesium oxide and strontium oxide.

[0027] The composite material is made of polyethylene, polypropylene, polyester, polyurethane, polyester, polypropylene fiber, nylon, glass fiber cloth, aluminum foil cloth, polytetrafluoroethylene, polystyrene material, and EVA. The thickness of the composite material is 300mm , the number of layers is 20 layers.

[0028] The fiber substrate is made of glass fiber, ceramic fiber, pre-oxidized silk fiber, aluminum silicate fiber, mullite fiber, basalt fiber, polyester fiber or carbon fiber.

[0029] (2) The sol complex is cont...

Embodiment 2

[0035] Fabricate airgel composites as follows:

[0036] (1) The following raw materials are weighed according to the weight ratio: 1 part of sol, 1 part of composite material and 100 parts of fiber substrate, and these raw materials are continuously mixed to carry out sol compounding;

[0037] The sol is composed of iron oxide, zinc oxide, magnesium oxide and strontium oxide.

[0038] The composite material is a mixture of nylon, glass fiber cloth, aluminum foil cloth, polytetrafluoroethylene, polystyrene material, and EVA. The thickness of the composite material is 0.1 mm, and the number of layers is 2 layers.

[0039] The fiber substrate is made of glass fiber, mullite fiber, basalt fiber, polyester fiber and carbon fiber.

[0040] (2) The sol complex is continuously mixed to form and solidify as a gel under the action of a quantitative lye as a catalyst;

[0041] (3) The gel is then subjected to supercritical drying to form an airgel felt;

[0042] (4) Continuously feed ...

Embodiment 3

[0046] Fabricate airgel composites as follows:

[0047] (1) Take the following raw materials according to the weight ratio: 250 parts of sol, 250 parts of hot melt adhesive, 100 parts of composite material and 250 parts of fiber substrate, and continuously mix these raw materials to carry out sol compounding;

[0048] The sol is composed of silicon dioxide, titanium oxide, iron oxide, zinc oxide, magnesium oxide and strontium oxide.

[0049] The composite material is a mixture of polyethylene, polypropylene and polyester, the thickness of the composite material is 250 mm, and the number of layers is 5 layers.

[0050] The fiber substrate is made of glass fiber, ceramic fiber, mullite fiber, polyester fiber and carbon fiber.

[0051] (2) The sol complex is continuously mixed to form and solidify as a gel under the action of a quantitative lye as a catalyst;

[0052] (3) The gel is then dried under negative pressure to form an airgel felt;

[0053] (4) Continuously feed the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com