Ceramic insulating electrical wire, composition,coil for coating and sound coil for loudspeaker

A technology of ceramic insulation and composition, applied in the direction of sensors, electrical components, etc., can solve problems such as reduction of coil characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

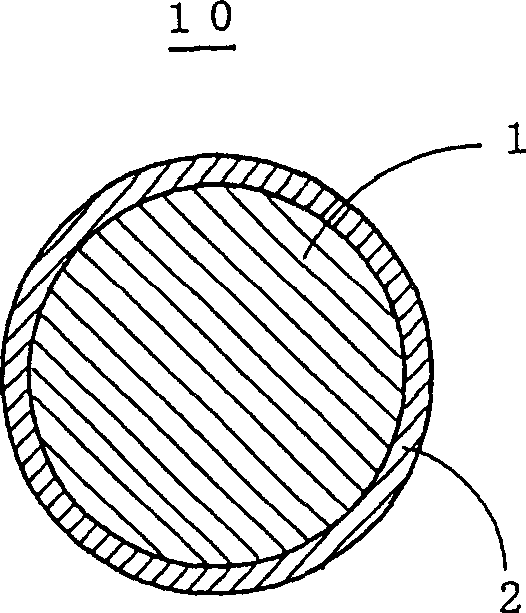

[0056] figure 1 It is a sectional view showing the ceramic insulated sheathed electric wire 10 according to the first embodiment of the present invention.

[0057] The ceramic insulating sheathed electric wire 10 has a structure in which a ceramic insulating film 2 is formed around a conductor 1 .

[0058] The above-mentioned conductor 1 is a copper wire with a diameter of 0.02-0.5 mm.

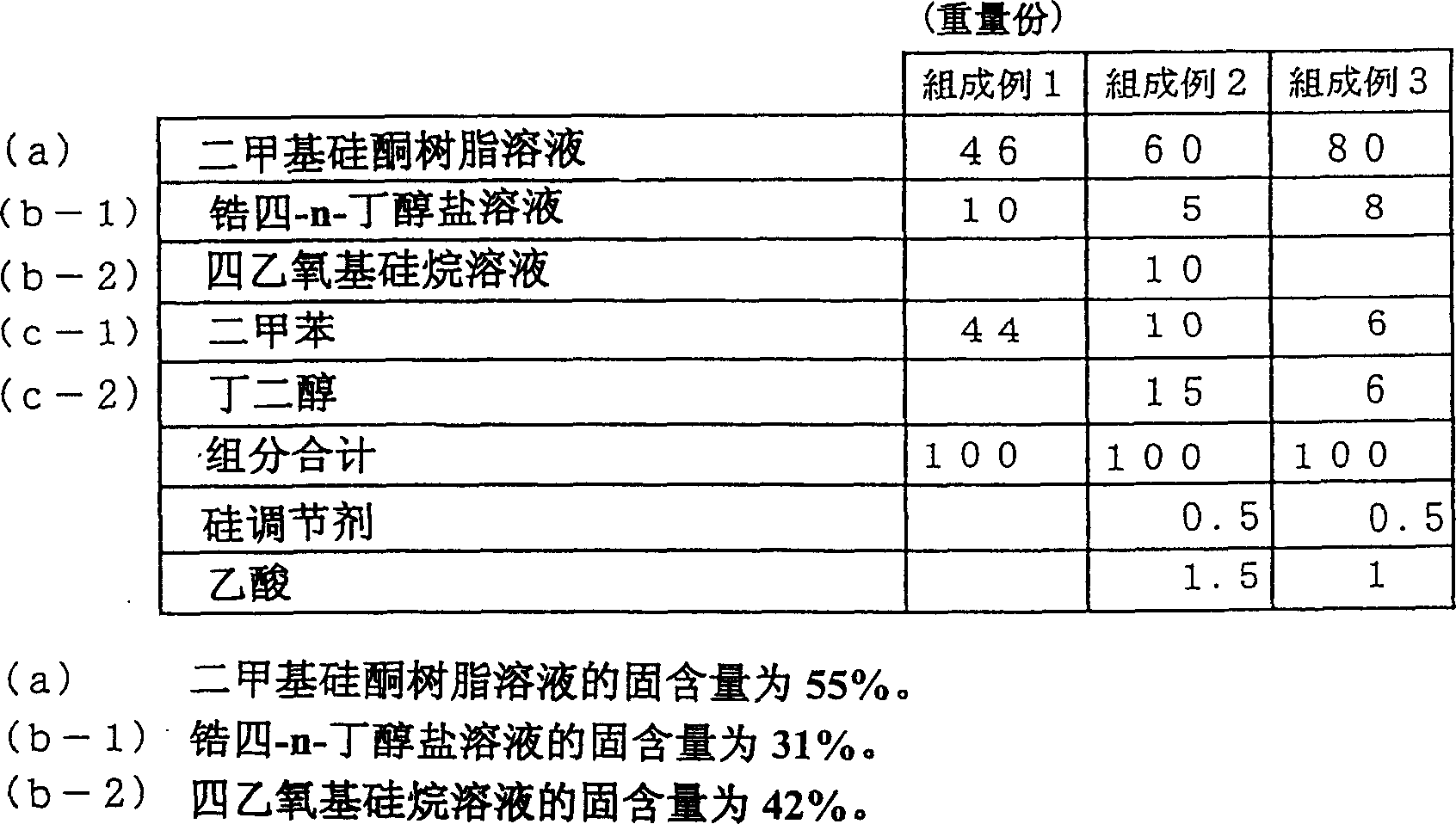

[0059] The above-mentioned ceramic insulating film 2 is to be figure 2 The coating composition described in Composition Example 1, Composition Example 2 or Composition Example 3 is applied on the conductor 1 and then thermally cured (heat-cured). The thickness of the ceramic insulating film 2 is 3 to 12 μm.

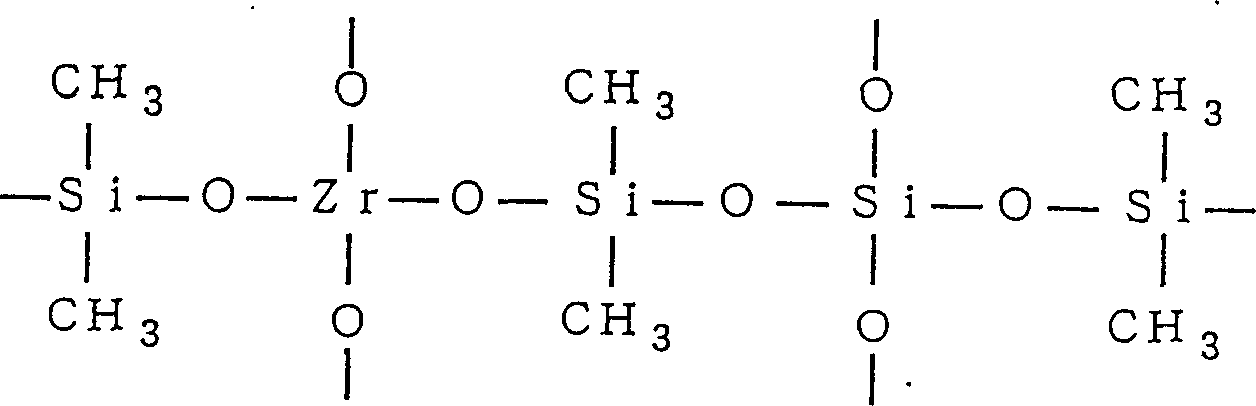

[0060] image 3 The chemical structural formula of the above-mentioned ceramic insulating film 2 is shown.

no. 2 Embodiment approach

[0062] Figure 4 It is a cross-sectional view showing a self-heat-fusible ceramic insulated sheathed electric wire 20 according to a second embodiment of the present invention.

[0063] This self-heat-fusible ceramic insulated electric wire 20 has a structure in which a heat-fusible film 3 is formed on the outer periphery of the above-mentioned ceramic insulated electric wire 10 .

[0064] The hot-melt film 3 is formed by applying a coating made of a polyamide resin or polyimide resin dissolved in an organic solvent on the ceramic insulated sheathed electric wire 10 and then thermally curing (heat curing). The thickness of the hot-melt film 3 is 3-10 μm.

[0065] The above-mentioned polyamide-based resin is used under the trade name of M1178 or M1603 from elf atchem Co., Ltd., Germany.

[0066] In addition, the said polyimide-type resin used the trade name BT2100 of Mitsubishi Gas Chemical Corporation.

no. 3 Embodiment approach

[0068] FIG. 5 is a cross-sectional view showing a speaker voice coil 30 according to a third embodiment of the present invention.

[0069] The structure of the speaker voice coil 30 is: the above-mentioned self-heat-fusible ceramic insulated sheathed wire 20 (outer diameter: 0.25mm) is wound around the periphery of the cylindrical bobbin 31 to form a winding wire (resistance value: 3.5Ω). , Heated at 190°C for 30 minutes to fuse the winding wires together. Among them, polyamide-based varnish is used for the fused sheath 3 of the self-heat-fusible ceramic insulated sheathed electric wire 20 .

[0070] The above-mentioned bobbin 31 is made of glass fiber cloth coated with polyimide resin.

[0071] Figure 6 It is a cross-sectional view showing a high-output speaker 40 using the speaker voice coil 30 described above.

[0072] The structure of this high output speaker 40 is: the voice coil 30 for the speaker is supported by the damper 42 on the frame 41, the vibration plate 43 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com