Manufacturing method for non-aqueous electrolyte secondary battery and used electrode thereof

A non-aqueous electrolyte, secondary battery technology, applied in the direction of non-aqueous electrolyte storage battery electrodes, non-aqueous electrolyte storage batteries, secondary battery manufacturing, etc., can solve problems such as reduced productivity, and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1~2

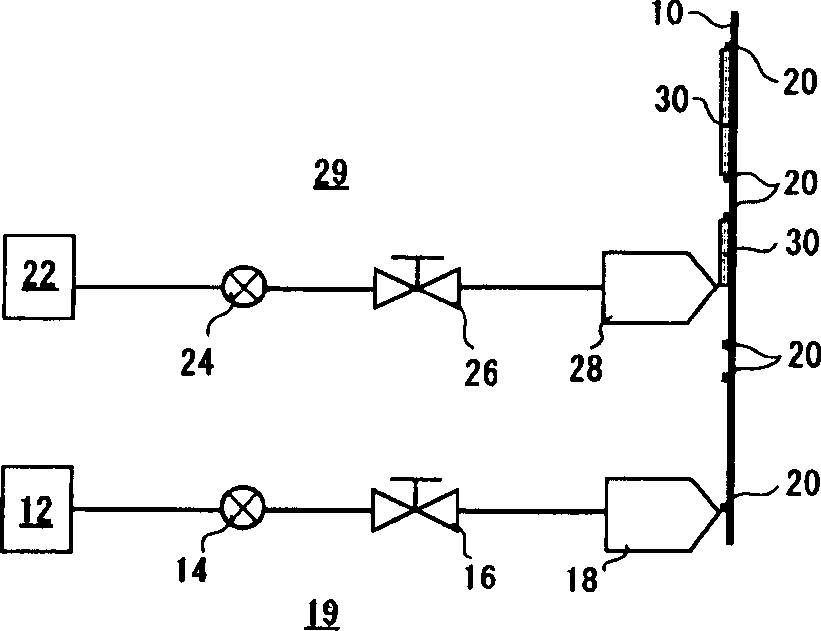

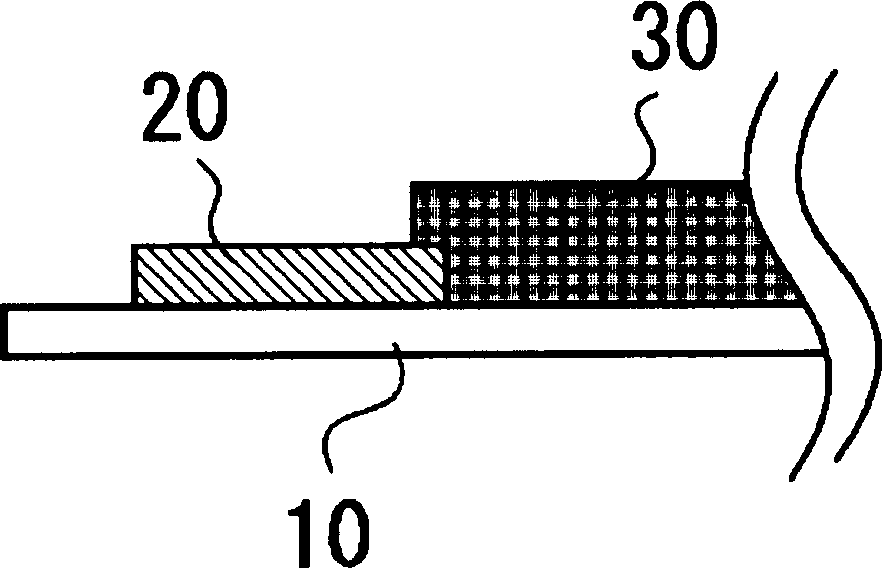

[0053] As Examples 1-3 and Comparative Examples 1-2, as figure 2 As shown, the insulating layer was manufactured by resin coating and drying method. First, a wide aluminum foil roll (not shown) commonly used as a positive electrode core (collector) is prepared so that it can be rolled from figure 2 move continuously from bottom to top. A 20% solution of polyvinylidene fluoride (PVdF) dissolved in N-methylpyrrolidone (NMP) solution is used as the coating resin 12. The insulating layer forming device 19 constituted by a die coater 18 is extruded and coated by a predetermined length at predetermined intervals to form the insulating layer 20 . Change the coating amount by controlling the gear pump 14, and change the thickness of the insulating layer 20 to 5 μm (comparative example 1), 10 μm (embodiment 1), 50 μm (embodiment 2), 180 μm (embodiment 3) and 300 μm (comparative example Example 2) Five types of samples were produced, and the electromagnetic valve 16 was electricall...

Embodiment 4、 comparative example 4

[0059] As Example 4, resin coating of the insulating layer was carried out at the time of manufacturing the positive electrode plate by the hot-melt method. That is, if Figure 4 As shown, a coating resin in which 95 parts of polypropylene and 5 parts of water-added □□□□ (trade name) resin were dissolved and mixed at 200° C. was melted with a heating and melting device 32 heated to 180° C. Control the amount of coating, while extruding through the switching solenoid valve 36 and the heating die slot (dieslot) 38, before and after the positive electrode active material mixture layer 42 of a specific length that is intermittently formed on the positive electrode core 40, an insulating layer is formed. Layer 44. Furthermore, the control of the coating position and coating length is performed while electrically controlling the switching solenoid valve 36 using a position detector (not shown), so that they are kept constant. The insulating layer 44 is formed as Figure 5 As show...

Embodiment 5

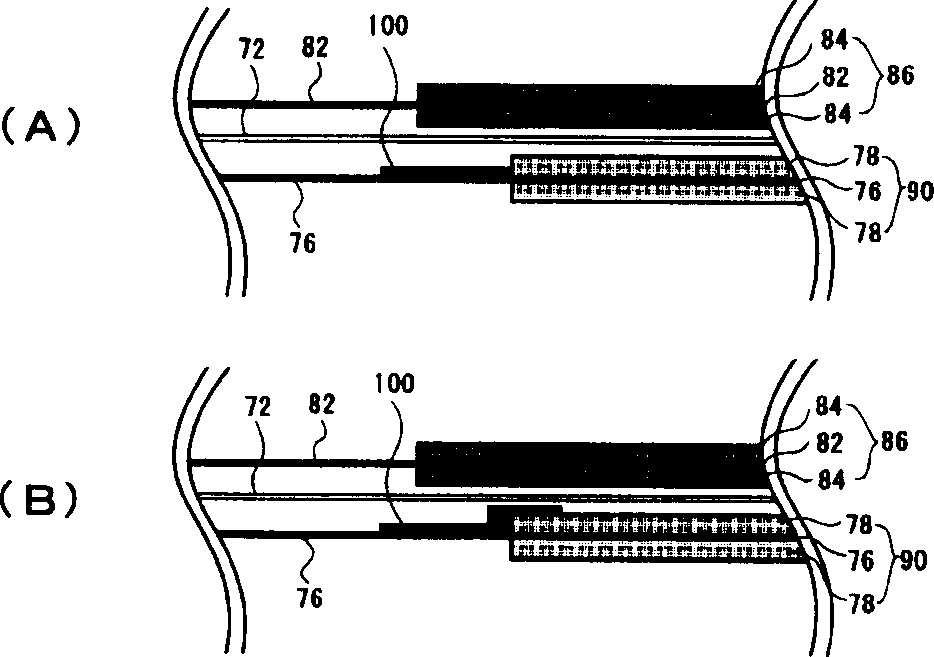

[0062] As Example 5, using a thermal bonding tape 48 made of an insulating tape made of polypropylene (PP) at the top and a thermoplastic resin made of ethylene-vinyl acetate copolymer (EVA) at the bottom, it was manufactured in the same manner as in Example 4. Paste on the positive plate. That is, if Figure 5 As shown, the sample formed with the positive electrode active material mixture layer 52 of a specific length and thickness formed on the positive electrode core body 50 in advance is continuously passed through the heating roller 54, and is held on the belt by a position detector (not shown). The heat-bonding tape 48 cut to a specific length on the holding portion 56 is automatically attached to the front and back of the positive electrode active material mixture layer 52 . At this time, since the heat-welding tape is hard, it can be adhered correctly and securely, and no gap or overlap will be generated between the positive electrode active material mixture layer 52 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com