Application device, removal device, application and removal system as well as application method, removal method, and application and removal method

A technology of a coating device and a coating method, which is applied in the direction of a device for coating liquid on a surface, a printing device, a spraying device, etc., and can solve the problems of increasing the cost and time of peeling off masking tape, waste of plating materials, and formation of difficult-to-dispose surfaces Masking and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

[0153] Next, a first embodiment of the present invention will be described with reference to the drawings. In addition, the dimensional ratios in the drawings may be different from actual ratios by exaggerating the ratios for the convenience of explanation.

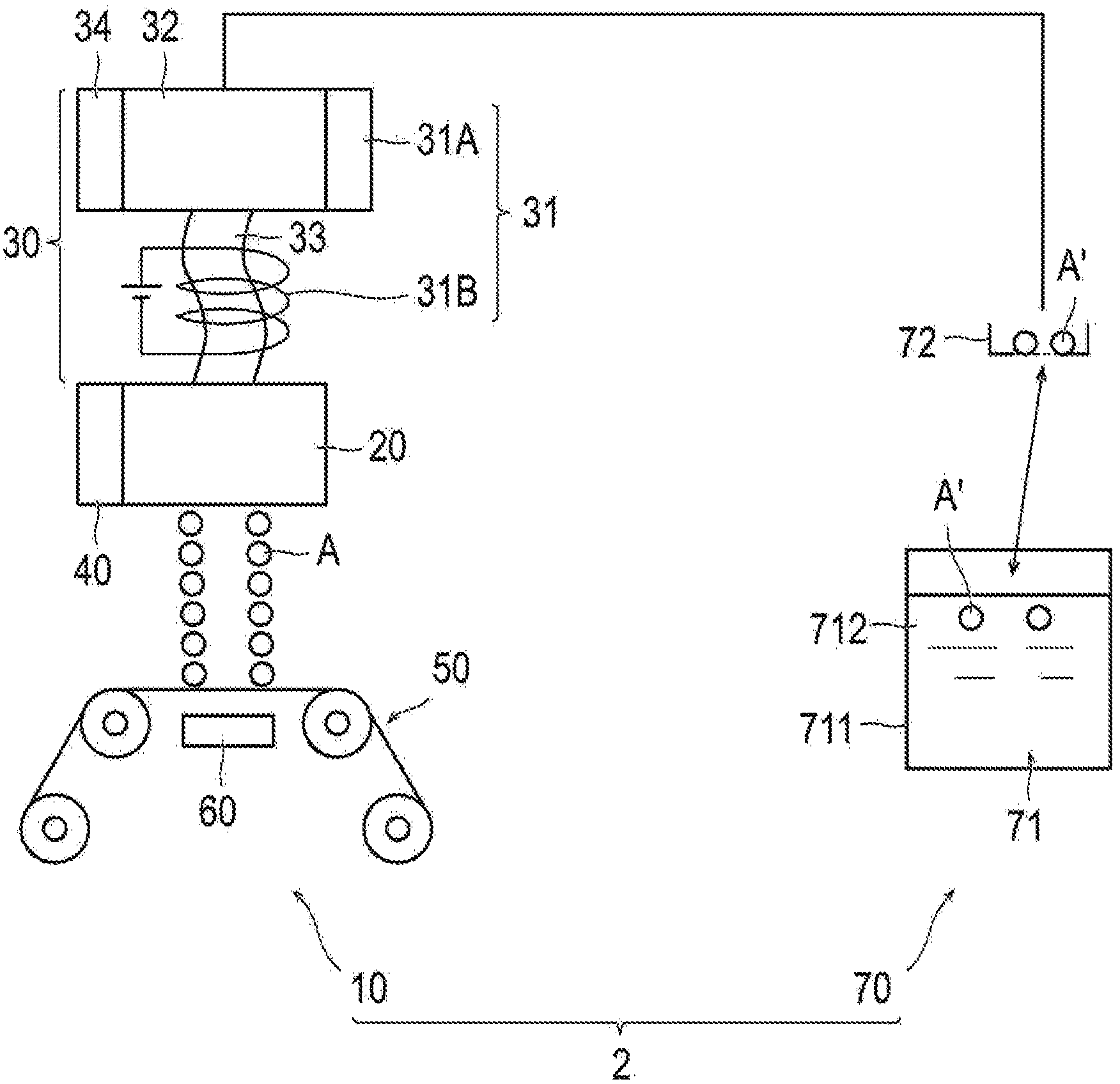

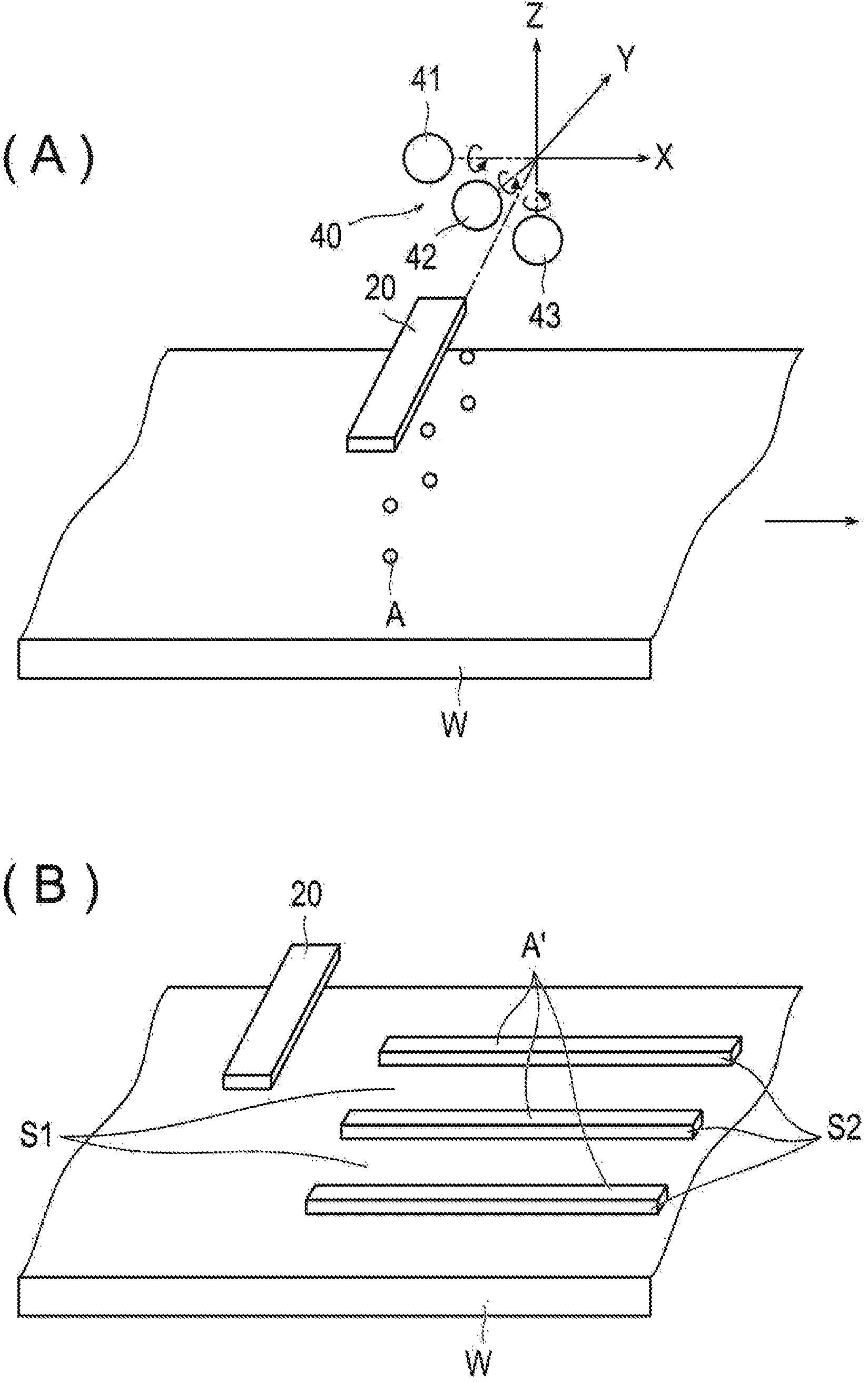

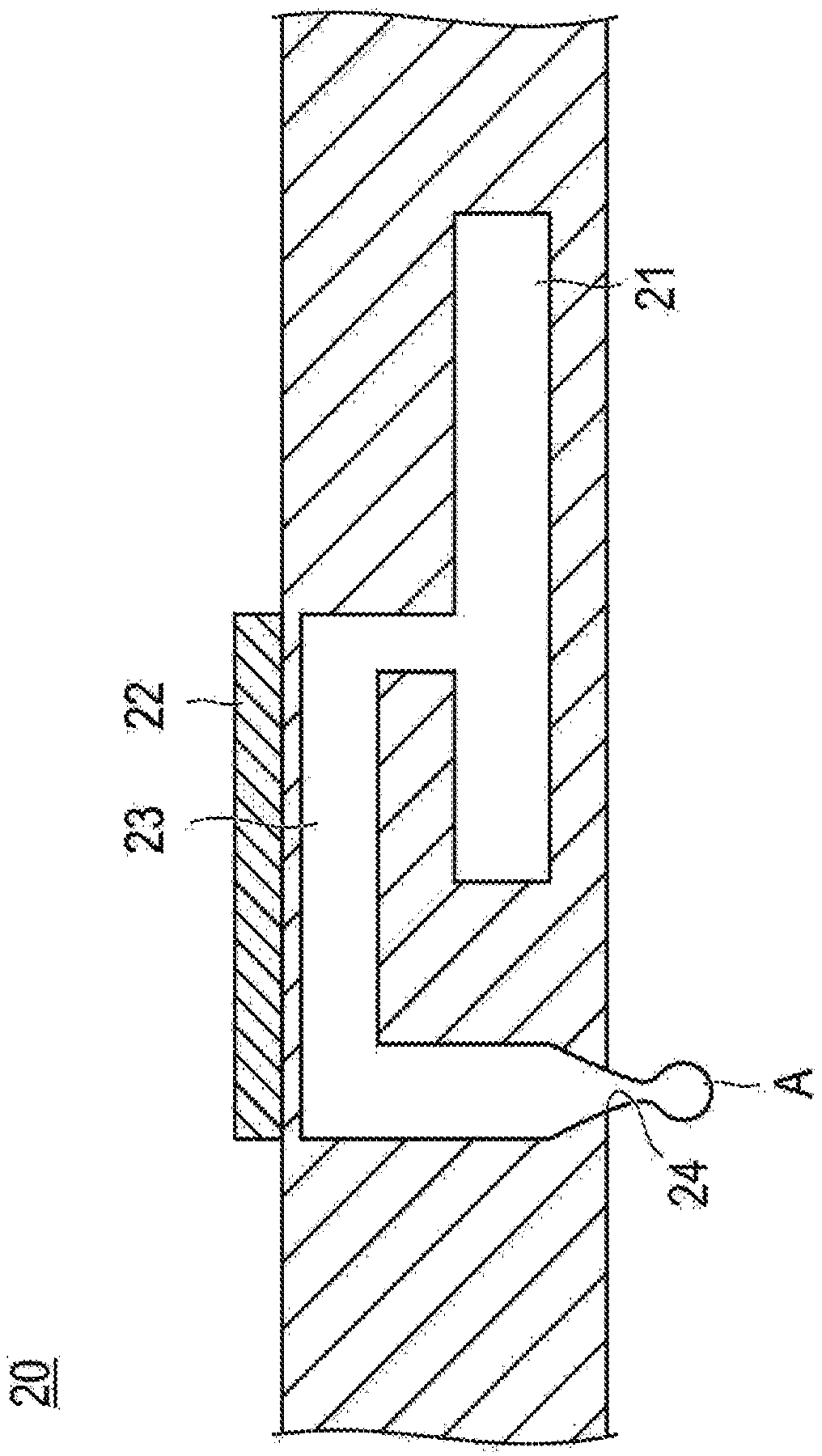

[0154] figure 1 It is a figure which shows the coating removal system 2 which concerns on 1st Embodiment of this invention. figure 2 (A) is a diagram showing a state in which the coating material A is applied to the non-treated surface S2 of the object W to be coated by the inkjet unit 20 of the coating device 10 according to the first embodiment, figure 2 (B) is a diagram showing the state of the object W after coating. in addition, figure 2 Among them, the direction in which the object to be coated W is conveyed is defined as the X direction (first direction), and the direction in which the rows of inkjet nozzles 24 of the inkjet unit 20 are arranged is defined as the Y direction (second direction), which is perpe...

no. 2 Embodiment approach >

[0233] Next, refer to Figure 10 , the coating removal system 5 according to the second embodiment of the present invention will be described. This embodiment differs from the first embodiment in that the removal device 170 further includes a melting removal unit 81 and a melting side recovery unit 82 . Hereinafter, the description of the parts common to the coating removal system 2 of the first embodiment will be omitted, and only the characteristic parts of the coating removal system 5 of the present embodiment will be described.

[0234] Coating removal system 5 of the present embodiment, such as Figure 10 As shown, there is a coating device 10 and a removal device 170 . The removal device 170 has a cooling removal unit 71 , a cooling side recovery unit 72 , a melting removal unit 81 , and a melting side recovery unit 82 . The configurations of the cooling removal unit 71 and the cooling side recovery unit 72 are the same as those of the first embodiment, and a detailed...

no. 3 Embodiment approach >

[0252] Next, refer to Figure 12 , the coating removal system 6 according to the third embodiment of the present invention will be described. This embodiment differs from the first and second embodiments in that the removal device 270 is composed of a melting removal unit 81 and a melting side recovery unit 82 .

[0253] Coating removal system 6 of the present embodiment, such as Figure 12 As shown, there is a melting and removing part 81, and the melting and removing part 81 is applied only to the non-treated surface S2 of the object to be coated W including the treated surface S1 subjected to surface treatment and the non-treated surface S2 not subjected to surface treatment. , the coating material A that is solid at room temperature and is liquefied by heating as a paraffin wax-containing masking agent A', the coating material A is melted into a liquid state by the liquid F1 having a temperature above the melting point of the paraffin wax and Remove from the object W to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com