UV (ultraviolet) paint veneering plywood and method for coating special-shaped base material

A technology for veneer plywood and plywood, which is applied in the joining of wooden veneers, chemical instruments and methods, wood processing appliances, etc., can solve the problems of inability to form veneer plywood, different sizes, and great harm to human body, etc. Achieve the effect of improving the decoration factory environment, improving the grade and improving the efficiency of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, describe the best implementation mode of the present invention through preferred embodiment, the specific implementation mode here is to illustrate the present invention in detail, and should not be interpreted as the limitation of the present invention, without departing from the spirit and essence of the present invention Various changes and modifications can be made within the scope of the present invention, and these should be included in the protection scope of the present invention.

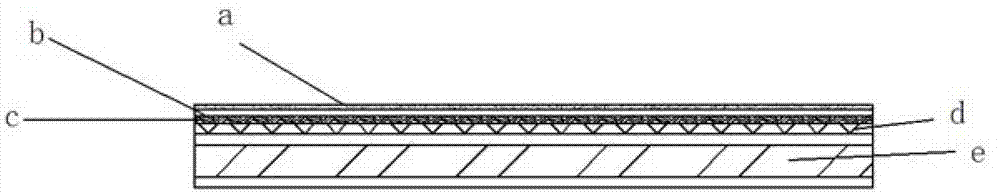

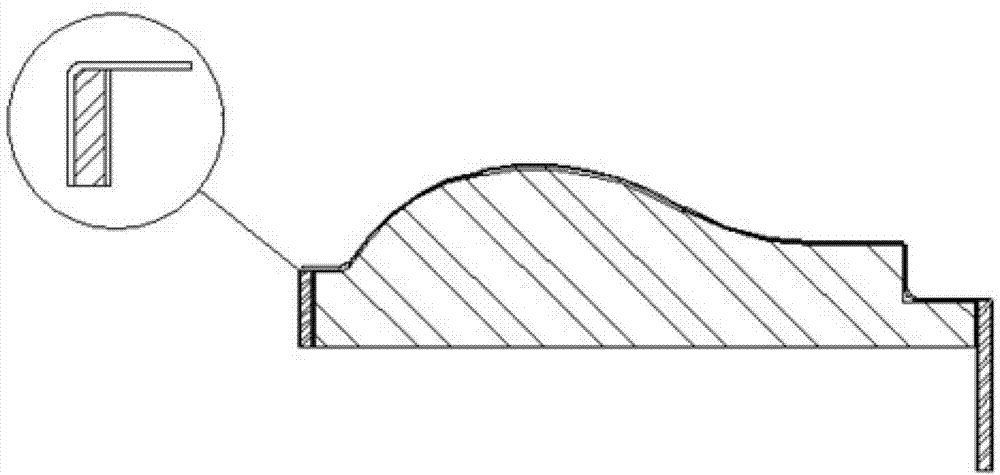

[0026] see figure 1 , which shows a schematic structural view of a UV-painted veneer plywood used for coating heterogeneous substrates in a preferred embodiment of the present invention. The UV paint-faced plywood used for covering heterogeneous substrates includes: heat-bendable plywood e, non-woven fabric d, veneer veneer c, UV paint surface b and PET protective film a.

[0027] The lower surface of the plywood that can be heated and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistant | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com