Paper and plastic composite light packaging film, manufacturing method thereof, and tag bag

A paper-plastic composite and manufacturing method technology, applied in the field of flexible packaging, can solve the problems of difficult packaging recycling, overly gorgeous decoration, and many packaging consumables, and achieve the effect of ensuring repeated use characteristics, high stiffness visual effects, and light and thin film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

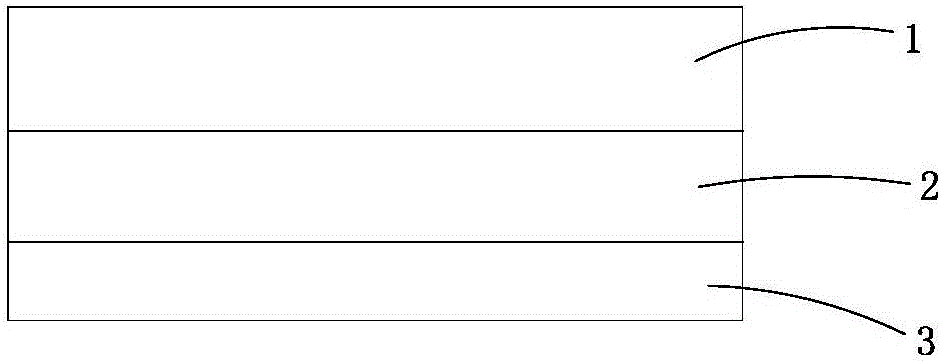

[0036] A paper-plastic composite light packaging film, such as figure 1 As shown, it includes an outer layer 1, an intermediate layer 2 and an inner layer 3 from the outside to the inside; the outer layer 1 is a BOPP film layer with a thickness of 15-20um, and the middle layer 2 has a grammage of 24-35g / ㎡ of kraft paper, the inner layer 3 is a PP film layer with a thickness of 15-25um.

[0037] As a preferred solution, the outer layer 1 is a BOPP film layer with a thickness of 18um, the middle layer 2 is kraft paper with a grammage of 30g / ㎡, and the inner layer 3 is a PP film layer with a thickness of 20um.

[0038] Aiming at the requirements of lightweight hygiene products for packaging materials and packaging structure, this patent adopts low-weight kraft paper with a grammage of 24-35g / ㎡ and ultra-light plastic film to compound, and designs a paper-plastic composite light packaging film. The film meets the packaging requirements of hygiene products in terms of strength, b...

Embodiment 2

[0040] A kind of manufacture method of paper-plastic composite light packaging film in embodiment 1, comprises the following steps:

[0041]S1: Prepare kraft paper and BOPP film; S2: Use the extrusion casting process to hot-melt coat the PP layer on one side of the kraft paper to obtain the composite structure of the middle layer and the inner layer; the main parameters of the extrusion casting process As follows: the temperature of the extrusion casting die is 300-320°C, and the winding and unwinding speed is 150-160m / min; after the kraft paper is hot-melt coated with PP, a cooling roll with a circulating cooling water at a temperature of 20°C±2°C is used inside Extruding and cooling to shape; S3: Bonding the BOPP film to the other side of the kraft paper by a composite process to obtain a paper-plastic composite light packaging film. In step S1, patterns are printed on the BOPP film, so as to improve the aesthetics.

[0042] In step S3 of this embodiment, the adhesive used ...

Embodiment 3

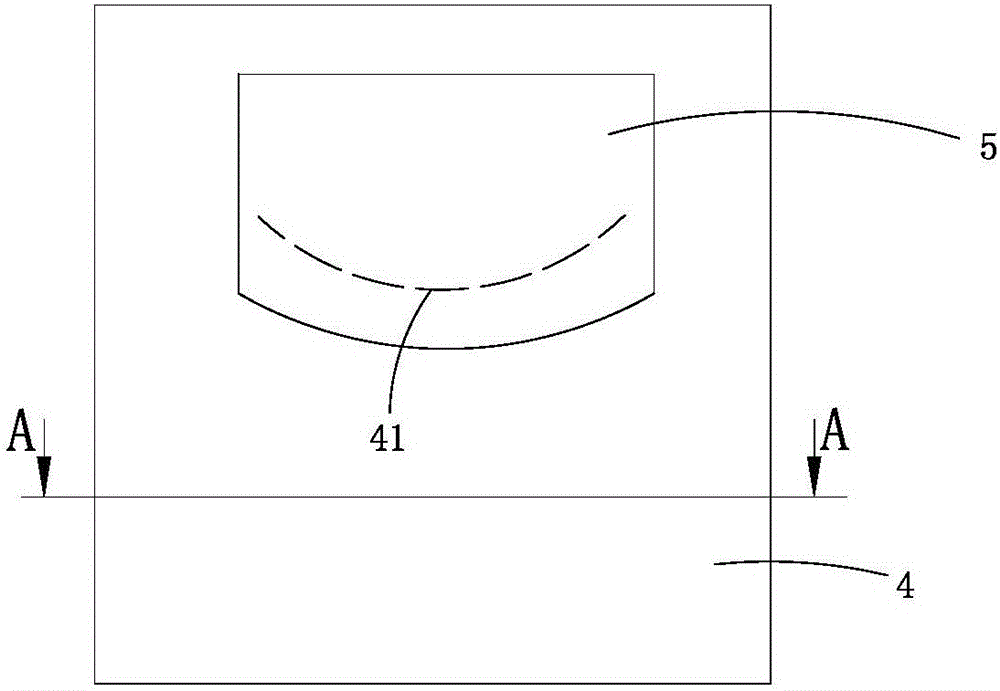

[0044] A label bag such as Figure 2 to Figure 4 As shown, the bag body 4 is included, and the bag body is made of the paper-plastic composite light packaging film described in Embodiment 1, and an unsealing incision 41 is opened on the surface of the bag body 4, and the corresponding part of the bag body 4 is There is a sealing label 5 covering the unsealing cut 41 , and the inside of the sealing label 5 has a removable adhesive layer 6 adhered to the surface of the bag body 4 . The selection of the removable adhesive layer 6 can realize the sealing and repeated opening of the bag body 4 .

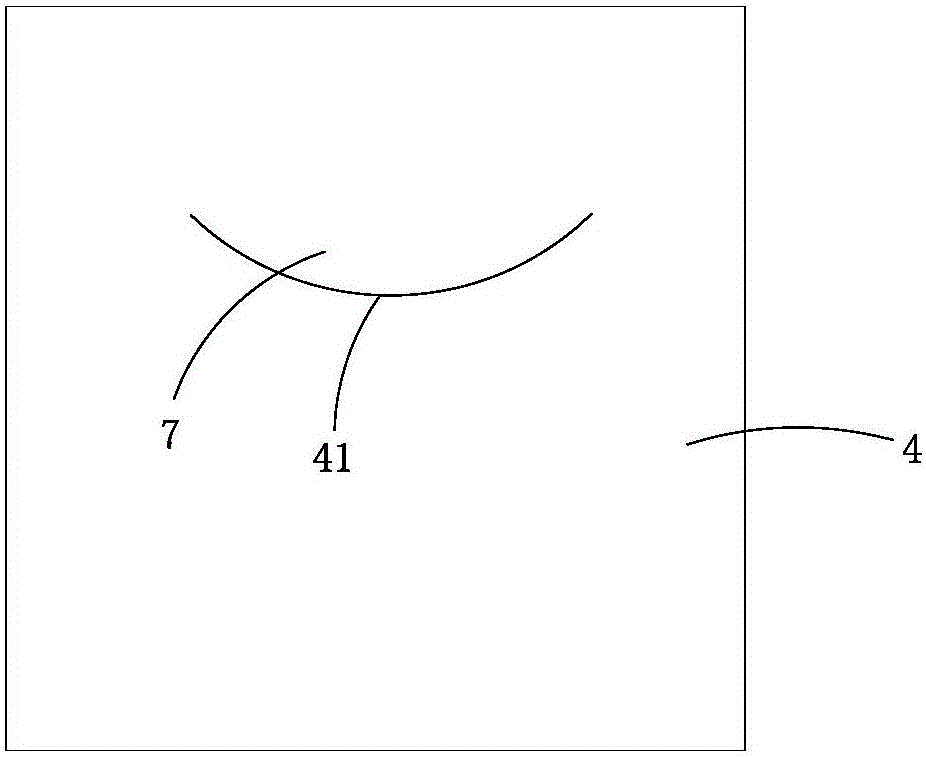

[0045] Further, the shape of the unsealing incision 41 is arc-shaped, and the inner part of the arc-shaped unsealing incision 41 forms a cover sheet 7 that can be folded outward, and the sealing label 5 fully covers the cover sheet 7, so The middle part of the sealing label 5 is bonded to the cover sheet 7, and the peripheral part of the sealing label 5 is bonded to the bag body 4. Adopt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com