Method for preparing fibers contained in a pulp suspension

a technology of fibers and suspensions, applied in the field of preparing fibers contained in pulp suspensions, can solve the problems of pcc pigments that are up to 10 times as expensive as pcc or gcc pigments, and have never been or never been considered for online production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

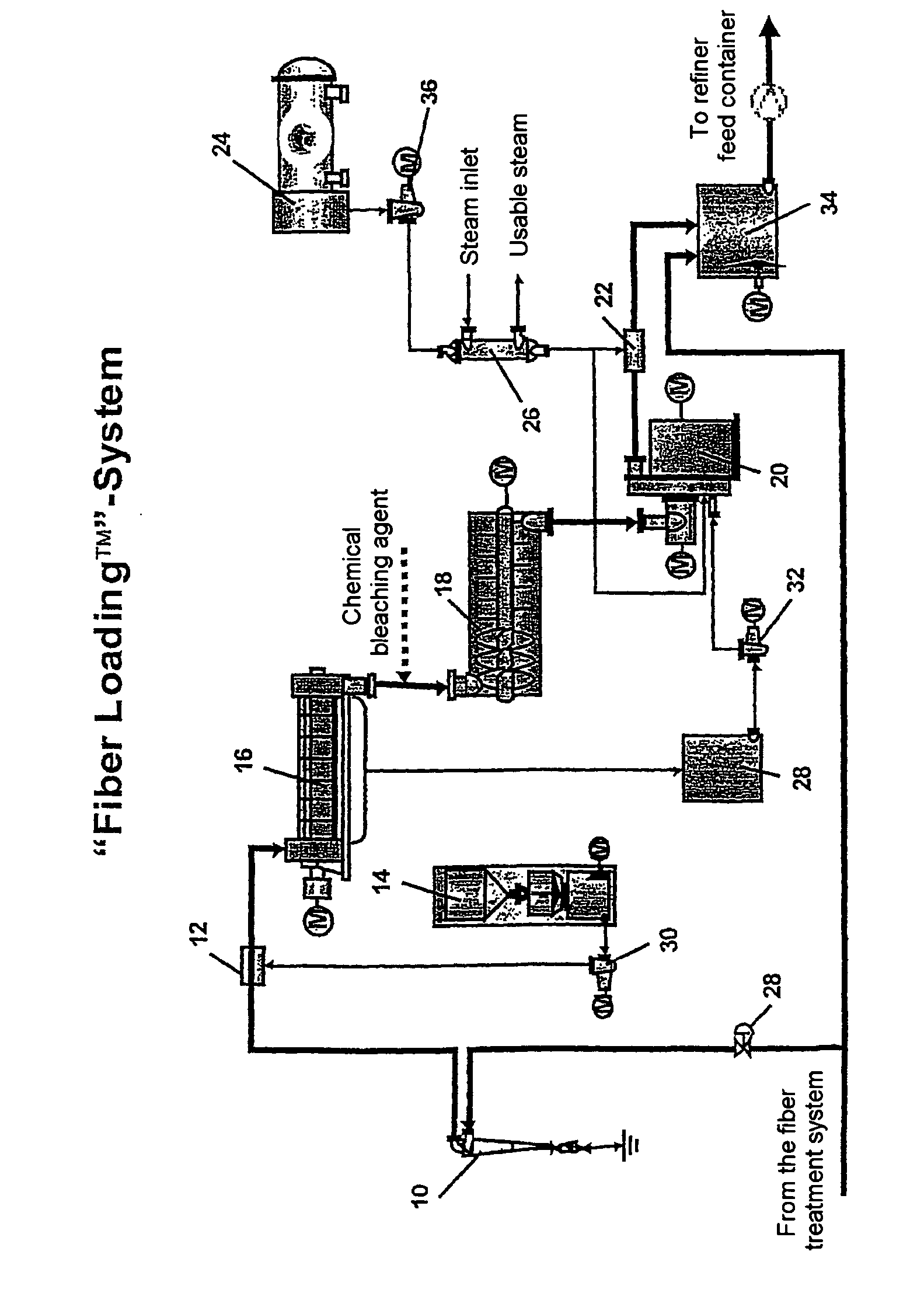

According to one embodiment of the present invention at least one of the following devices can be used: a cleaning device, in particular HC cleaner, a mixing device, in particular a static mixer, a lime slaking device, a press, in particular a screw press or belt press, a balancing reactor, a crystallizer, a further mixing device, in particular a static mixer, a CO2 supply device or additional CO2 recovery device, an optional CO2 heater, an optional chemical bleaching agent addition and / or a press water tank.

The formation of crystalline precipitation product particles is associated, inter alia, with the advantage that, if required, relatively high gloss values for the end product can be achieved. It is to be noted that, as a rule, only loaded fibers are ground. The coating color is not ground as a rule but can be ground. In general, this depends on the respective definition, but also on the respective crystallization operation. If CaCO3 crystals are produced in the coating kitche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com