Coated white-top kraft liner board and manufacturing method thereof

A manufacturing method and kraft liner technology, which is applied in the manufacturing field of coated white-faced kraft liner, can solve problems such as low strength, paper sheets are easy to break, and cannot be broken, so as to meet high-strength packaging, reduce paper wool problems, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

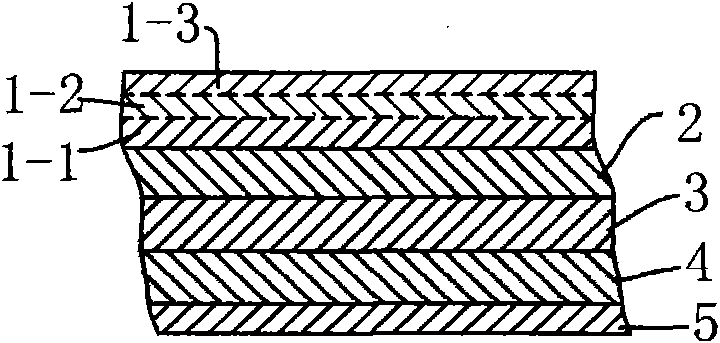

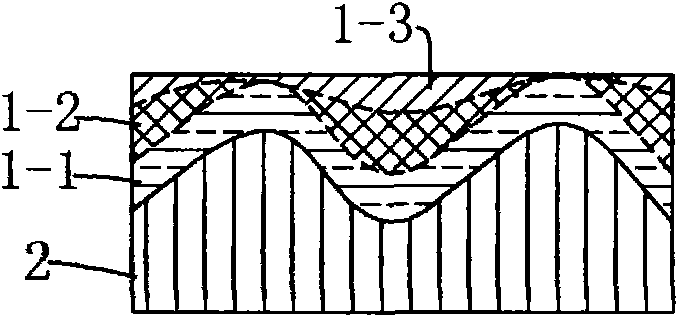

Image

Examples

Embodiment 1

[0027] 1. Pulping

[0028] a. Beat the wood pulp to a degree of beating of 30-40°SR to prepare the surface layer pulp.

[0029] b. Beat recycled old books, old newspapers, and office waste paper to a beating degree of 45-55°SR to prepare lining layer slurry.

[0030] c. Beat the OCC long-fiber pulp to a degree of beating of 30-40°SR to prepare the bottom layer pulp.

[0031] 2. Coating preparation

[0032] Coating formula: see Table 1, Table 2 and Table 3.

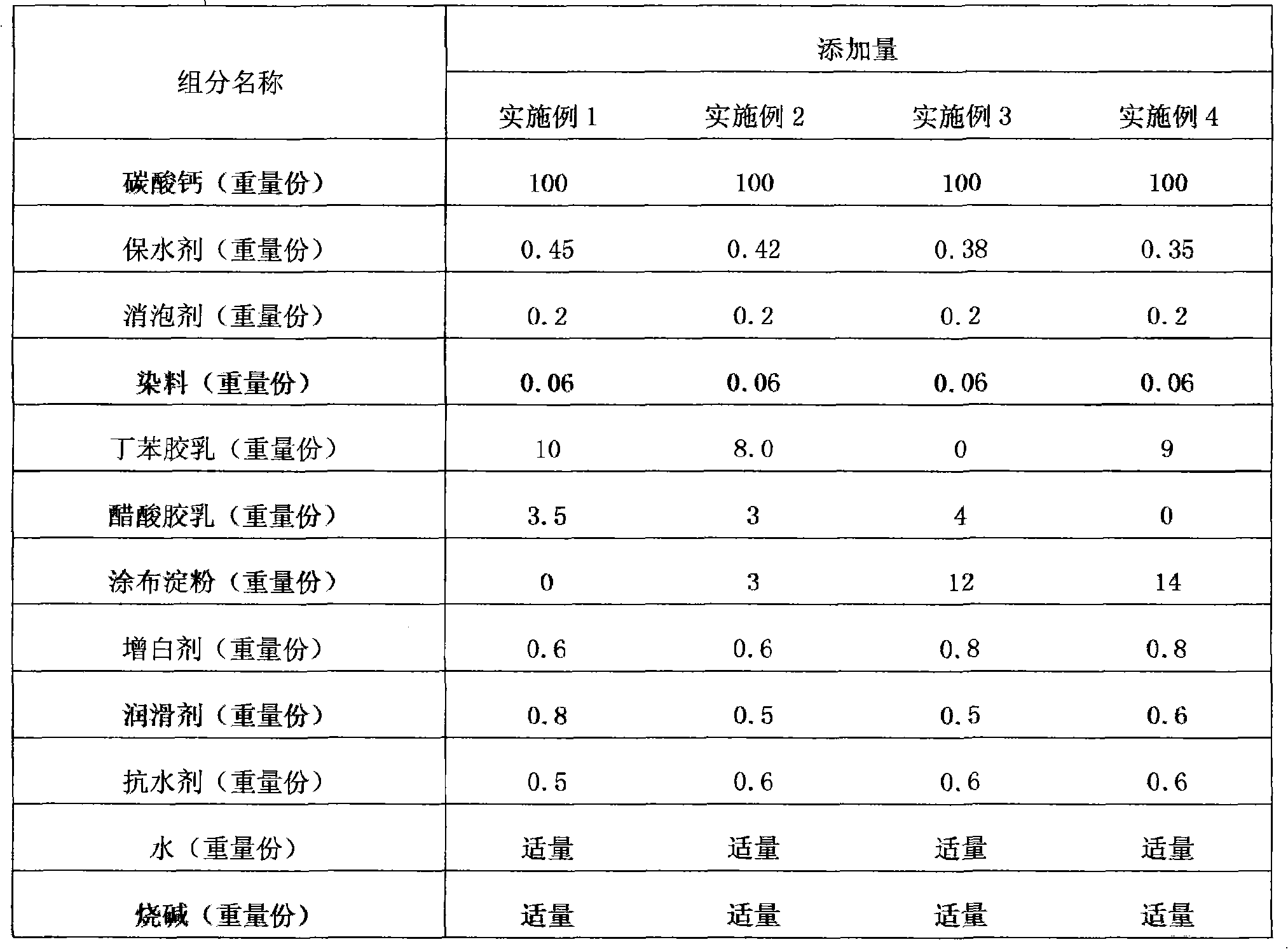

[0033] Table 1 Precoat paint formulation

[0034]

[0035] Table 2 Zhongtu coating formulation

[0036]

[0037]

[0038] Table 3 top coating formulation

[0039]

[0040]

[0041]In table 1, table 2 and table 3, the preferred heavy calcium carbonate of described calcium carbonate, the average particle diameter of fine-grained kaolin described in table 2 and table 3 is 0~2 μ m, and described exfoliated kaolin is made of average particle diameter less than The 2μm fine-grained kaolin is obtained by exfo...

Embodiment 2

[0058] Embodiment 2 is basically the same as Embodiment 1, and its difference lies in the formula of coating, and the coating formula of embodiment 2 is shown in Table 1, Table 2 and Table 3.

[0059] Quantitative 150g / m made by the above process 2 The technical indicators of coated white-faced kraft linerboard are shown in Table 4.

Embodiment 3

[0061] Embodiment 3 is basically the same as embodiment 1, and its difference lies in the formula of coating, and the coating formula of embodiment 3 is shown in Table 1, Table 2 and Table 3.

[0062] Quantitative 175g / m produced by the above process 2 The technical indicators of coated white-faced kraft linerboard are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com