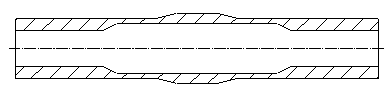

Method for manufacturing fracture surface changing seamless aluminium-alloy tubular product

An aluminum alloy, variable section technology, used in metal extrusion dies, metal extrusion mandrels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

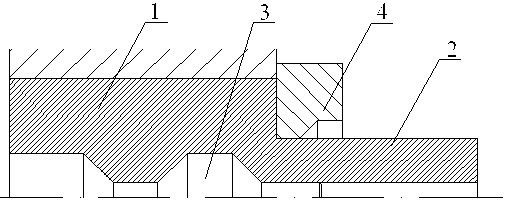

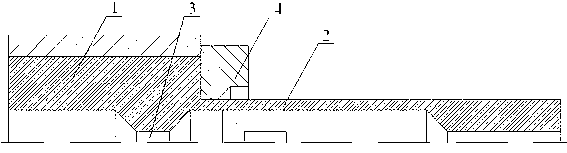

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] As shown in the figure, 1 is the pipe raw material, 2 is the product, 3 is the extrusion needle, and 4 is the mold.

[0020] The extrusion machine extrudes the pipe material 1 through the movable extrusion needle 3, and the working surface of the extrusion needle 3 for extruding variable-section seamless pipes is divided into three parts, which correspond to the inner thickening part, normal The size part and the outer thickening part. During production, the front part of the extrusion needle 3 is fixed in the extrusion die 4 and just begins to extrude (as figure 2 ). The extruded tube in this state is the inner thickening of the front end. The extrusion needle 3 moves forward, because the gap between the die 4 holes and the extrusion needle 3 decreases, the wall of the raw material 1 becomes thinner, and the normal size part of the extruded pipe front end (such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com