Tubular pipe fastener

A clamping device and bobbin technology, applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., to achieve the effects of suppressing the diameter from becoming smaller, increasing the rotation speed, and making the operation easier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

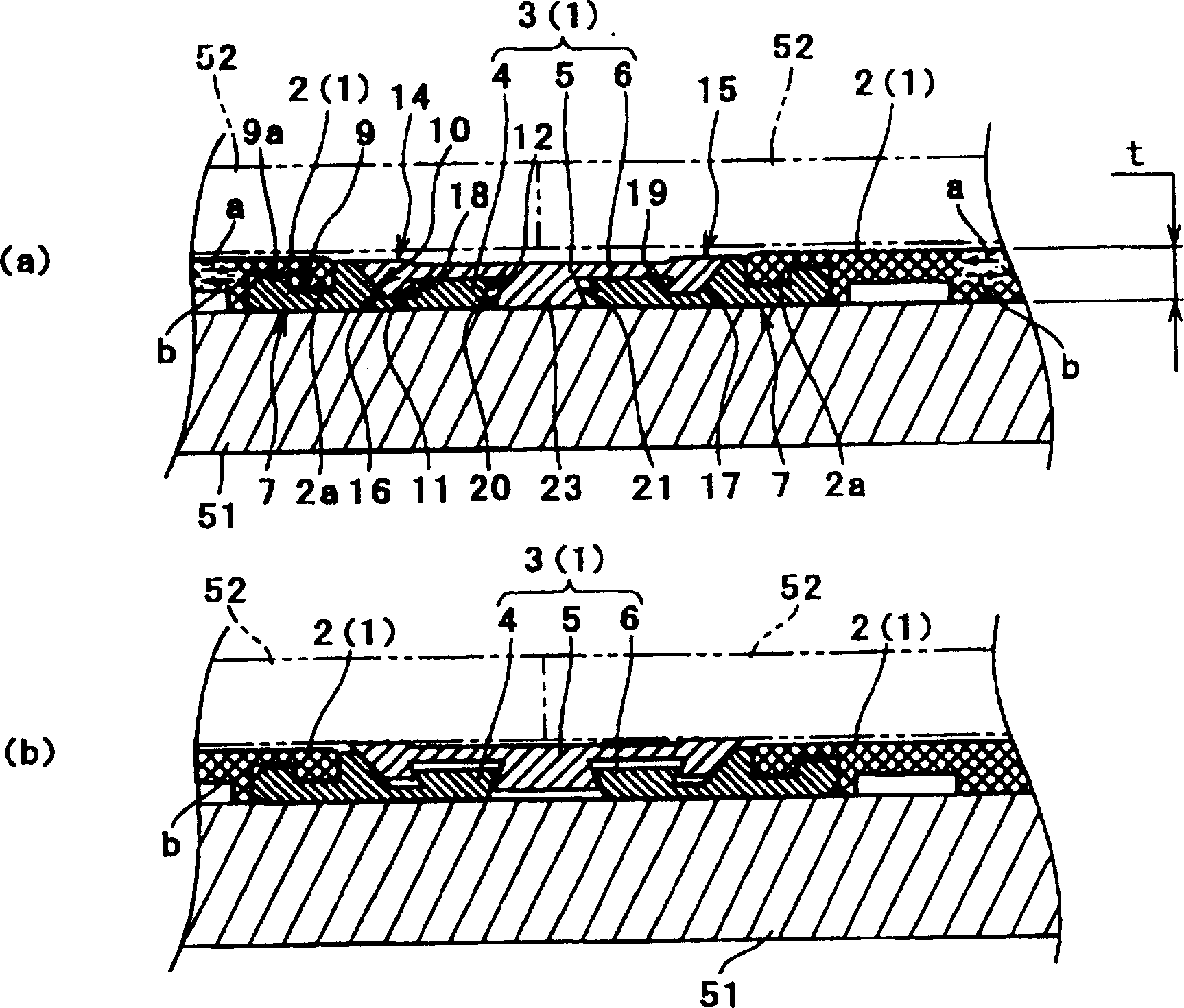

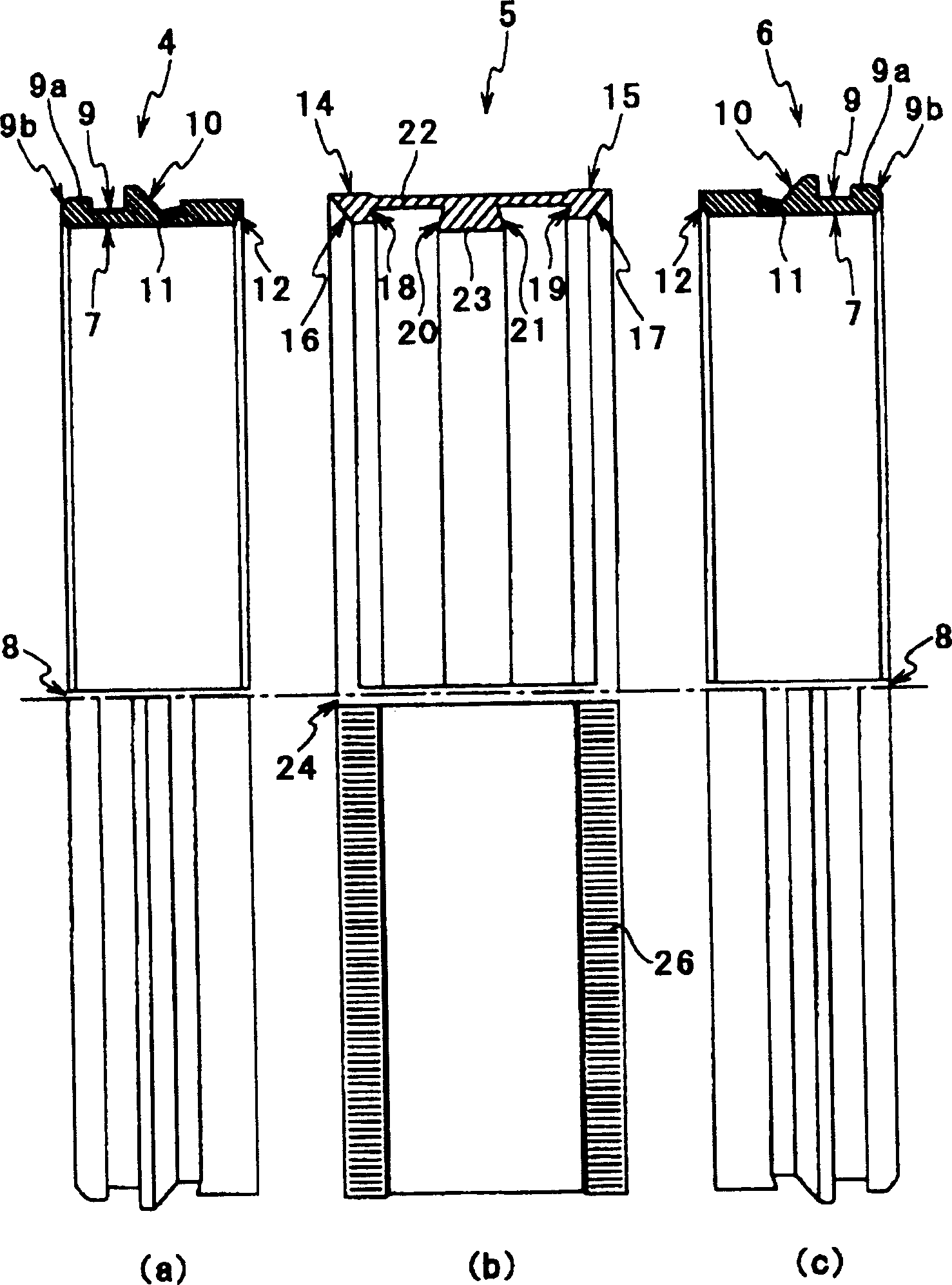

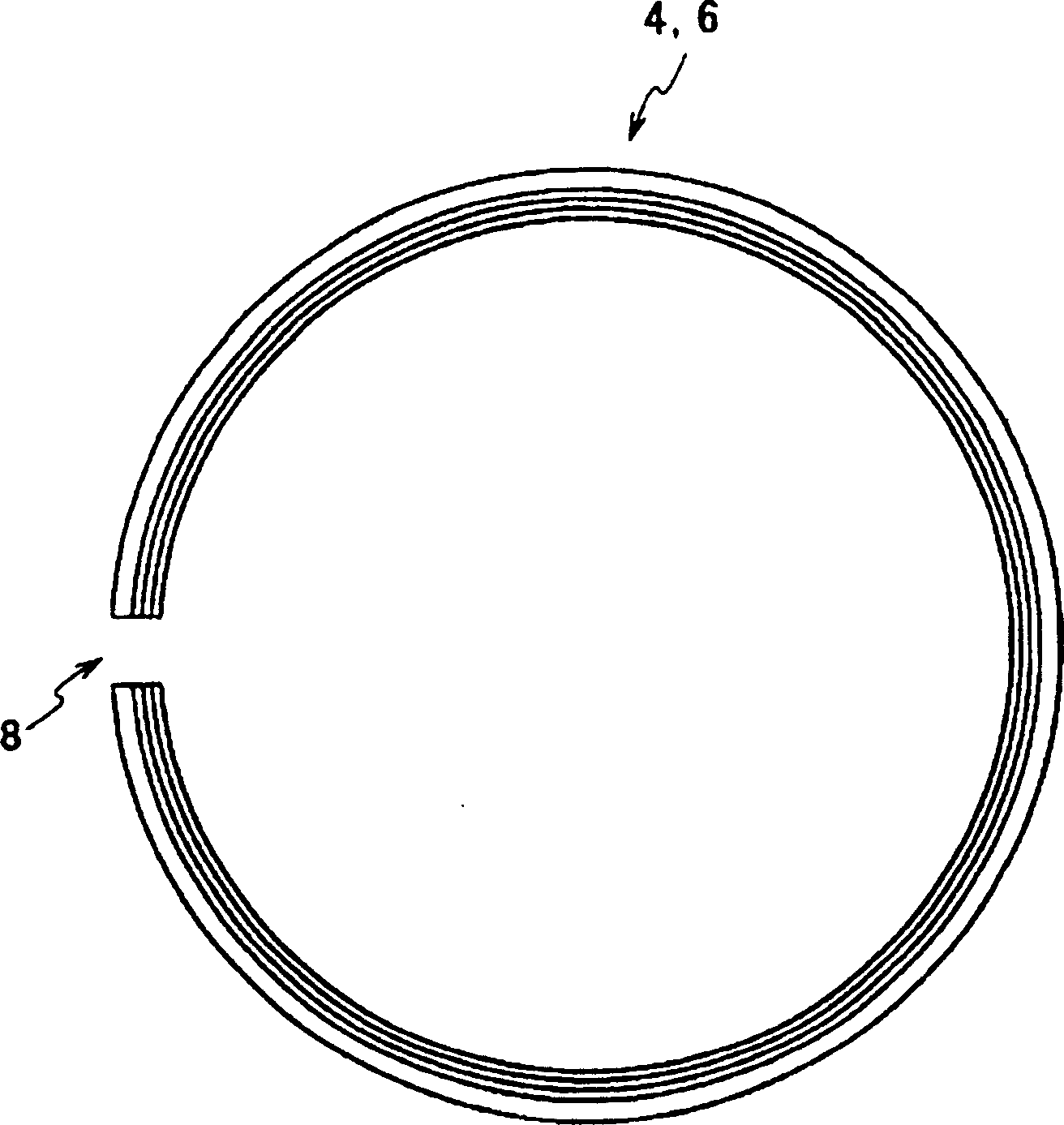

[0030] Next, a bobbin clamp device 1 according to an embodiment of the present invention will be described with reference to the drawings. figure 1 The main part of the bobbin clamping device 1 of the present embodiment is shown, and the cylindrical bobbin 52 for winding the yarn is detachably attached to the rotating cylinder 51 as the main body of the bobbin holder so that it can be held. state.

[0031] figure 1 The illustrated bobbin clamping device 1 includes an isolating ring 2 inserted on a rotating cylinder 51 and a clamping member 3 that holds or releases bobbins as the isolating ring 2 moves back and forth along the axis of the bobbin holder. figure 1 (a) shows the state where the clamp member 3 has released the bobbin 52, figure 1 (b) shows the state in which the bobbin 52 is held (clamped state).

[0032] Before describing the structure of the bobbin clamp device 1 in detail, the bobbin holder 50 using the bobbin clamp device 1 will be described. Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com