Stator for rotary electrical machine

A technology for rotating electrical machines and stators, which is applied in the field of stators and can solve the problems of increasing and increasing the size of the stators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

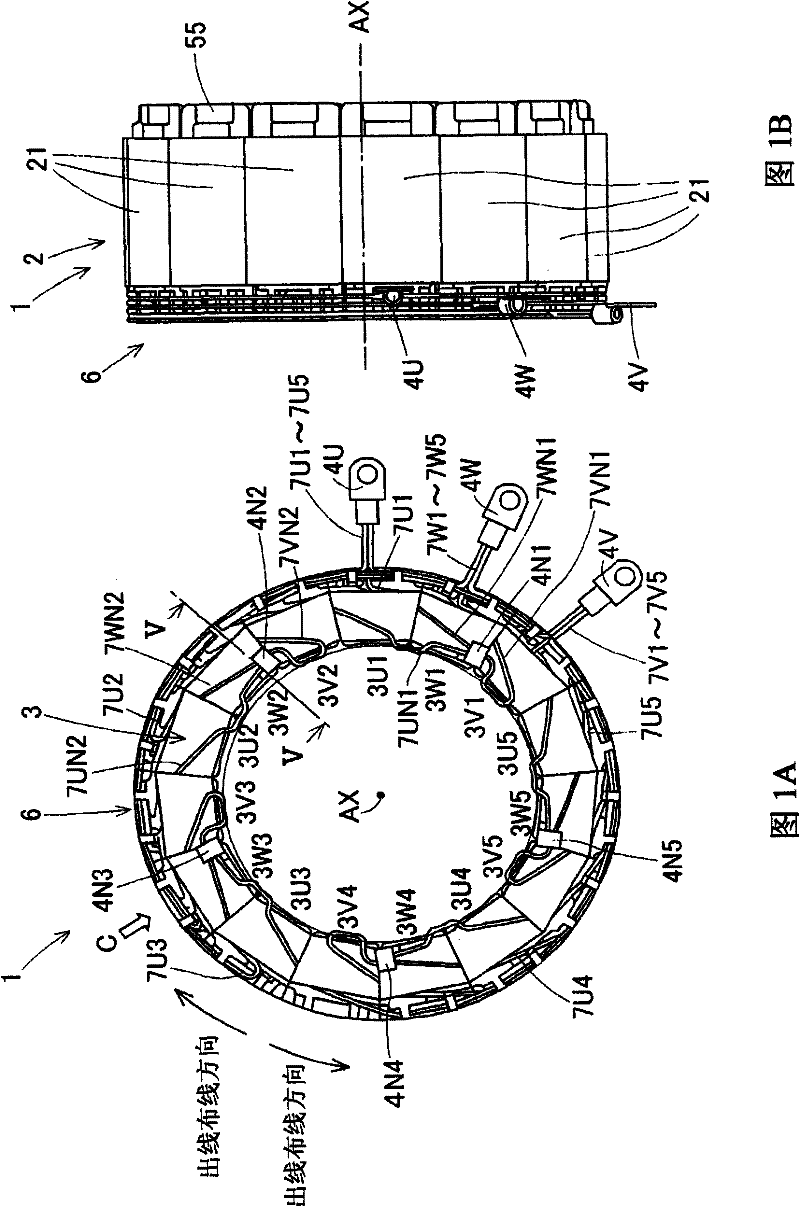

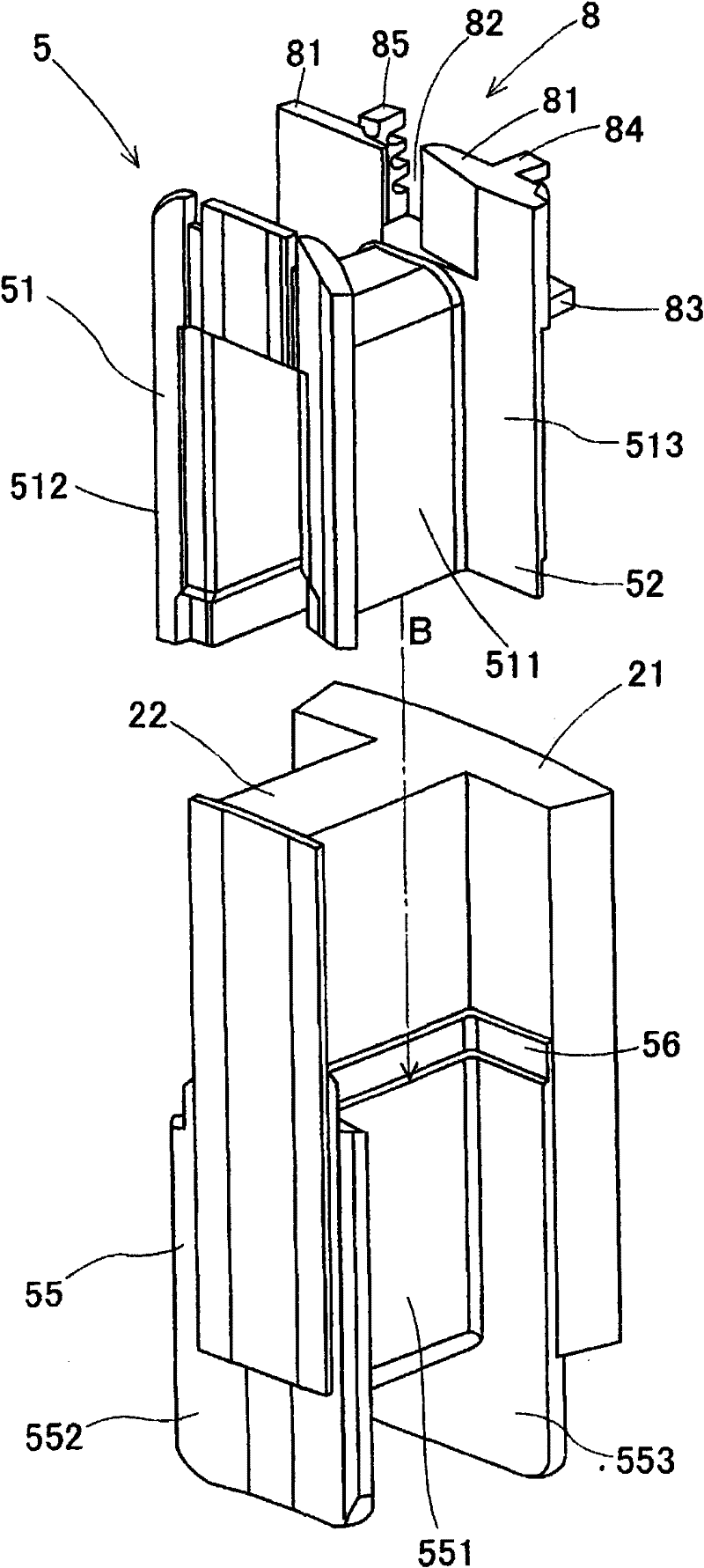

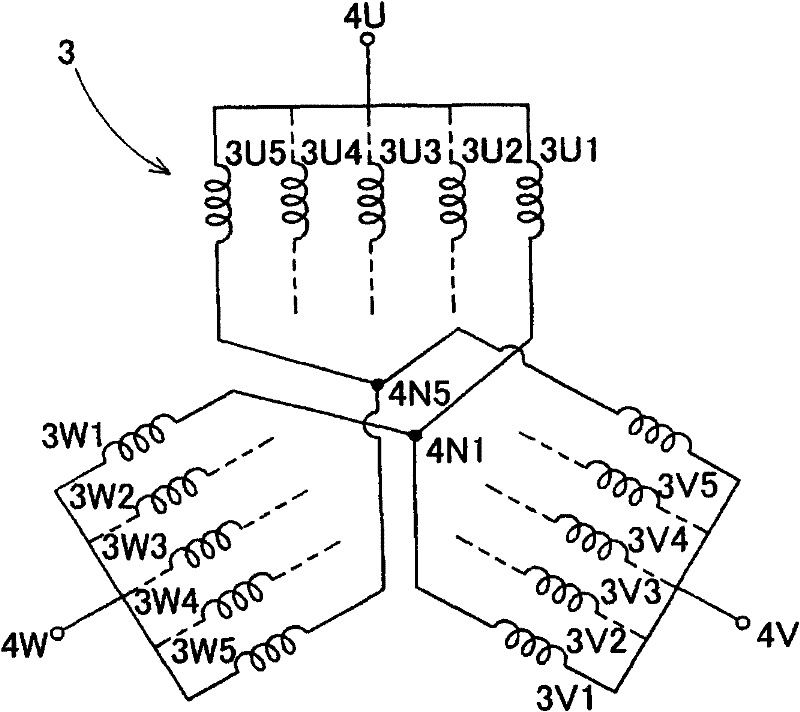

[0038] Below, with reference to Figures 1 to 1 in the accompanying drawings Figure 6 , illustrates the stator 1 of the rotating electrical machine according to the first embodiment. Figure 1A and Figure 1B Shown is a diagram for explaining the stator 1 of the rotating electric machine according to the first embodiment. in particular, Figure 1A Shown is a plan view of the stator 1 of the rotating electric machine according to the first embodiment, as viewed in the direction in which its axis AX extends. Figure 1B Shown is a side view of the stator 1 of the electric rotating machine according to the first embodiment. The electric rotating machine is configured such that the stator 1 is arranged on the outer peripheral portion of the electric rotating machine, and the rotor is arranged on the radially inner side of the stator 1 . In addition, the rotary electric machine is formed approximately symmetrically with respect to the axis AX. As shown in FIG. 1 , a stator 1 incl...

no. 2 example

[0064] Below, refer to Figure 9 The stator 10 of the rotating electrical machine of the second embodiment will be described. The stator 10 of the electric rotating machine according to the second embodiment differs from the stator 1 of the electric rotating machine according to the first embodiment in the groove portion formed at the power supply insulating portion 80 which is formed at the same angle as that formed at the power supply insulating portion 8 . The groove portions 86U, 86V, and 86W have different shapes. In the second embodiment, differences between the stator 1 of the rotating electrical machine according to the first embodiment and the stator 10 of the rotating electrical machine according to the second embodiment will be mainly explained. Figure 9 Shown is a sectional view of a stator 10 of a rotating electric machine according to a second embodiment. The basic configuration of the stator 10 according to the second embodiment is the same as that described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com