Manufacturing method of special-shaped pipe

A production method and special-shaped tube technology are applied in the production field of integrated seamless special-shaped tubes, which can solve the problems of difficult circulation of refrigeration medium, safety, leakage, etc., and achieve the effects of high production efficiency, smooth circulation and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

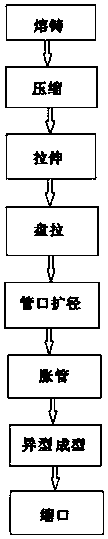

Image

Examples

Embodiment 1

[0019] Embodiment 1: Take a special-shaped pipe with a pipe diameter of 15 mm and a wall thickness of 0.8 as an example;

[0020] Step 1: melting and casting;

[0021] The finished copper plate material is melted into copper water in a high-temperature melting furnace, and is extruded and formed into a copper tube billet through a tube mold, and an oxide layer is formed on the outer surface of the tube billet, and the oxidized surface is allowed to be oxidized and washed;

[0022] Step 2: Compression, stretching, coil drawing and cutting;

[0023] Compress the raw material of the hollow copper tube billet into a hollow copper tube semi-finished product. The diameter of the tube wall is from thick to thin, the tube diameter is compressed to 90mm-50mm, and the tube wall is 3.0mm-2.6mm. Carry out stretching treatment, the strength of stretching is 400KN, the stretching speed is 180m / min, the stretching is a movable copper tube structure, the diameter of the tube wall becomes thi...

Embodiment 2

[0030] Embodiment 2: Take the special-shaped pipe with a pipe diameter of 50mm and a wall thickness of 1.2mm as an example;

[0031] like figure 1 As shown, the preparation method includes the following steps:

[0032] Step 1: melting and casting;

[0033] The finished copper plate material is melted into copper water in a high-temperature melting furnace, and is extruded and formed into a copper tube billet through a tube mold, and an oxide layer is formed on the outer surface of the tube billet, and the oxidized surface is allowed to be oxidized and washed;

[0034] Step 2: Compression, stretching, coil drawing and cutting;

[0035] Compress the raw material of the hollow copper tube billet into a hollow copper tube semi-finished product. The diameter of the tube wall is from thick to thin, the tube diameter is compressed to 90mm-75mm, and the tube wall is 4.0mm-3mm. Stretching treatment, the stretching force is 300KN, the stretching speed is 120m / min, the stretching is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com