Boiler economizer with supersonically sprayed abrasion and corrosion resistant coating

A technology of supersonic spraying and anti-corrosion coating, which is applied in the direction of coating, feed water heater, preheating, etc. It can solve the problems of water-cooled pipe cracking, sealing failure, dust emission, etc., and achieve water saving and wear resistance and the effect of increased corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

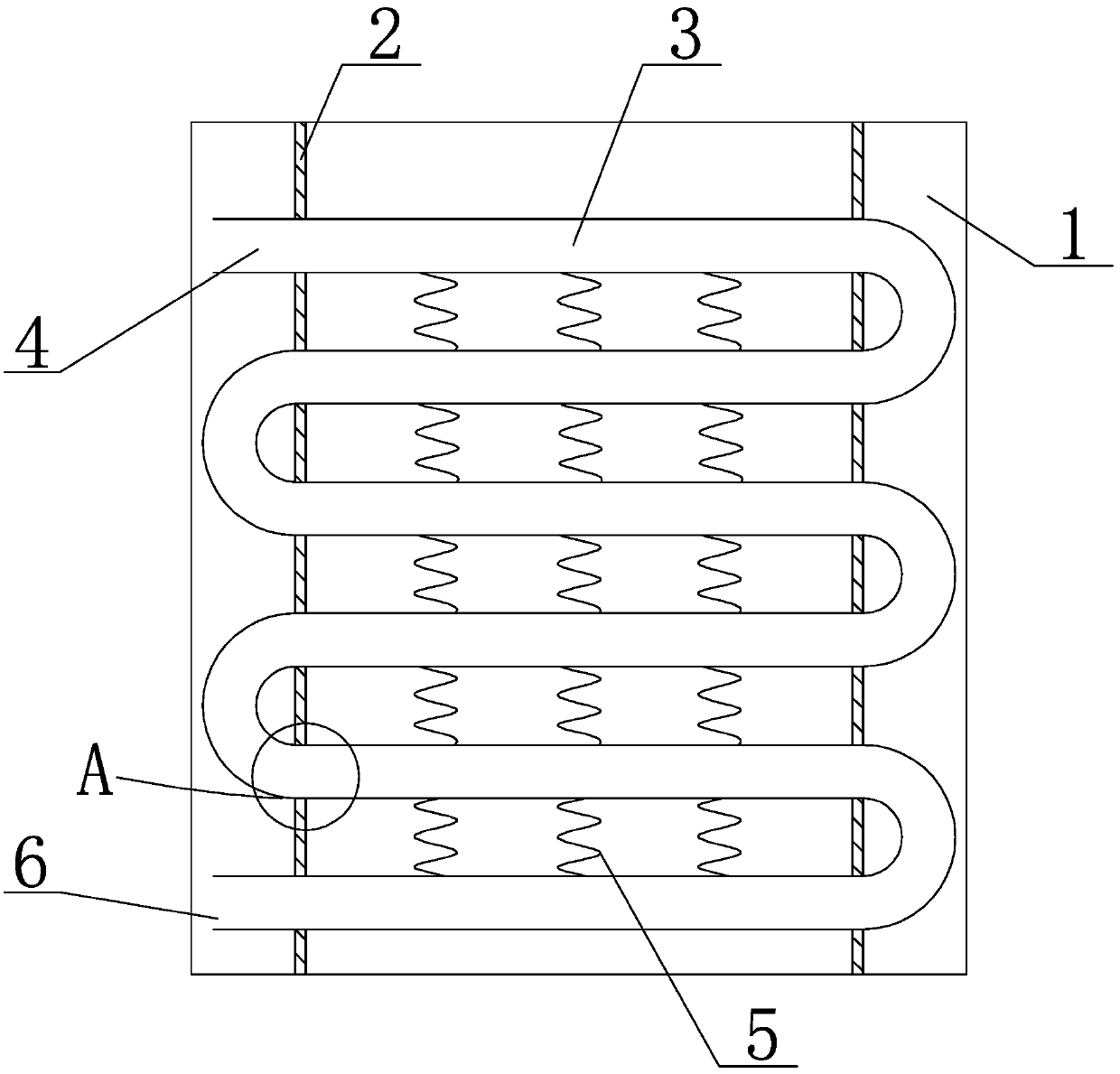

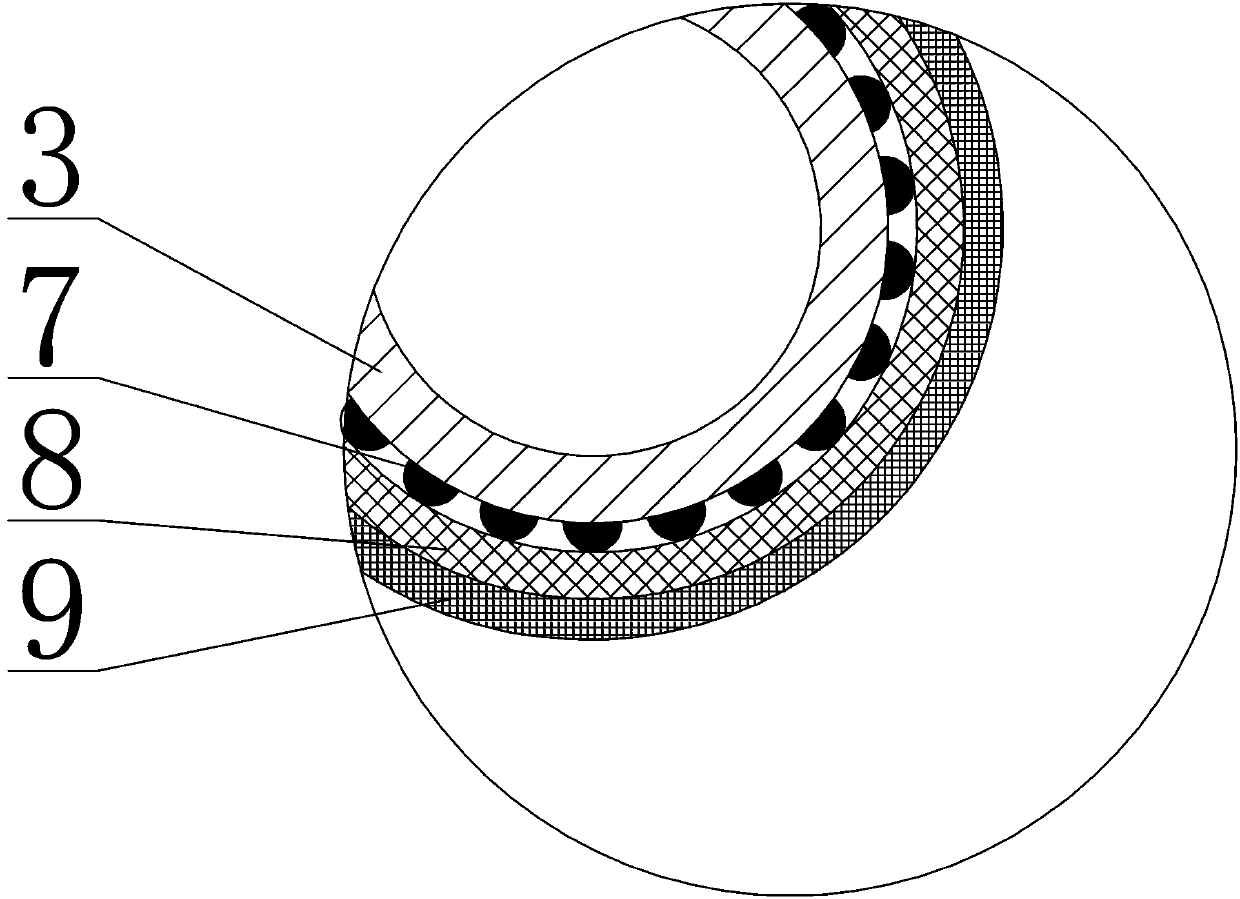

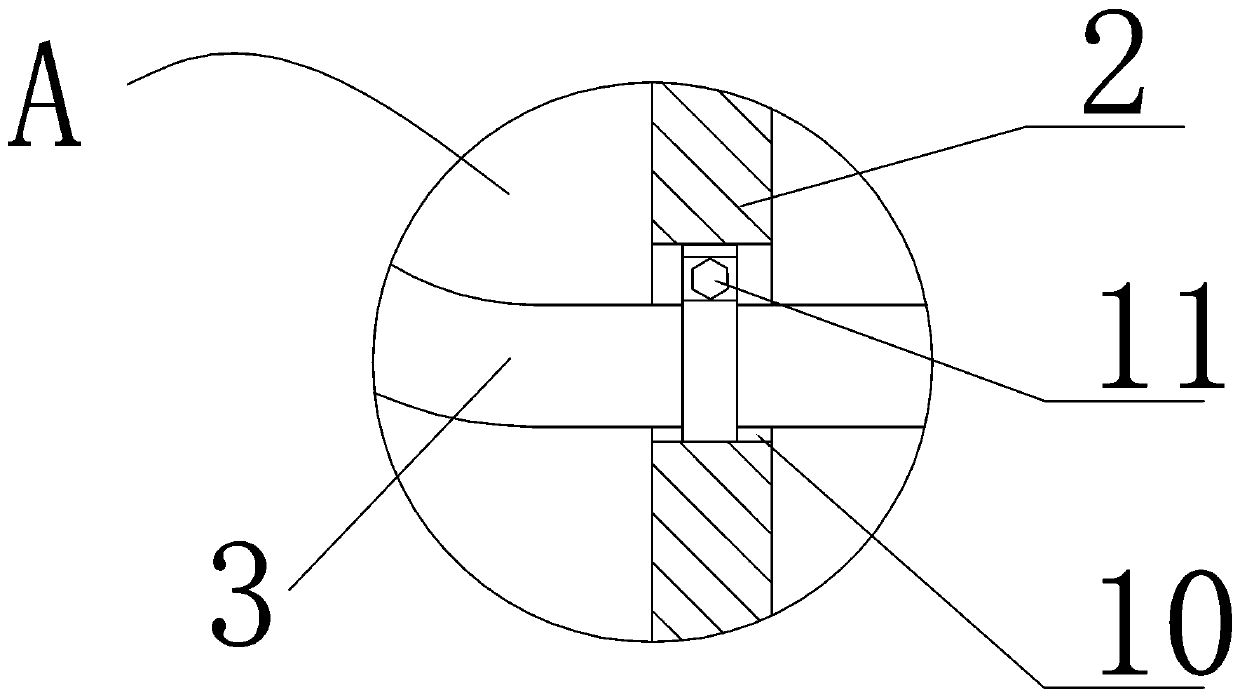

[0017] like Figure 1-3 As shown, a boiler economizer with supersonic spraying wear-resistant and anti-corrosion coating includes a fire-resistant wall 1, and the outer wall of the fire-resistant wall 1 is vertically provided with multiple sets of support plates 2, and the support plates 2 Water-cooling tubes 3 are arranged laterally on the outer wall, and the water-cooling tubes 3 are evenly arranged on the outer wall of the support plate 2. The top left end of the water-cooling tube 3 is provided with a water outlet 4, and the bottom left end of the water-cooling tube 3 is provided with a water inlet 6. An elastic member 5 is installed between adjacent water-cooled pipes 3, the outer wall of the water-cooled pipe 3 is sprayed with a corrosion-resistant coating 7, the outer wall of the corrosion-resistant coating 7 is sprayed with a high-temperature res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com