PPO/PA alloy material suitable for wall thinning and preparation method thereof

An alloy material and thin-walled technology, which is applied in the field of PPO/PA alloy material and its preparation, can solve problems such as the inability to meet large-sized thin-walled parts, and achieve the effect of improving flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

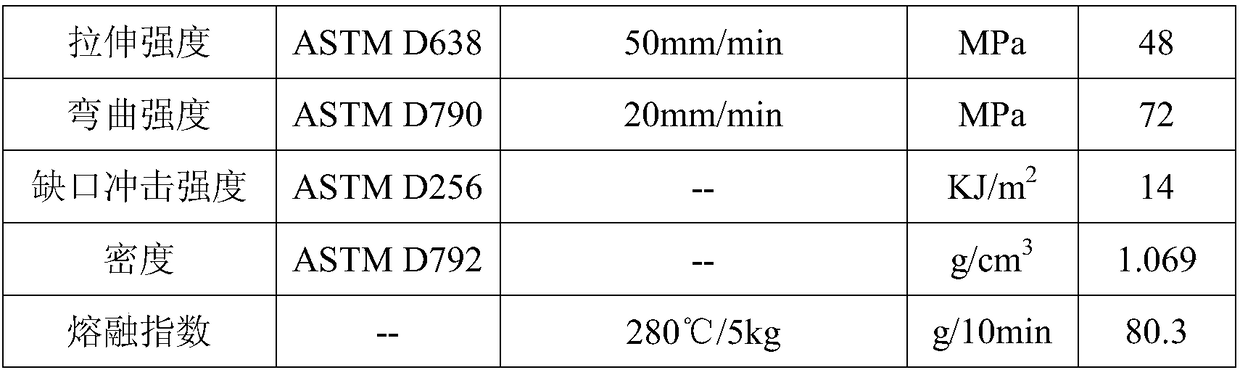

Embodiment 1

[0025] 1): Take 20 parts of PPO resin and 61.2 parts of PA resin according to the weight ratio, and dry them in an oven; add 5 parts of compatibilizer, 12 parts of toughening agent, 1.5 parts of flow modifier, and 0.3 parts of antioxidant Stir and mix in a high-speed mixer for 3 to 5 minutes;

[0026] 2): The material obtained in step (1) is fed into the twin-screw extruder through the main feeder, and melted and extruded through the twin-screw extruder. The extrusion process is: twin-screw extruder temperature zone: one zone Temperature 190℃~250℃, zone 2 temperature 220℃~270℃, zone 3 temperature 270℃~300℃, zone 4 temperature 270℃~300℃, zone 5 temperature 270℃~300℃, zone 6 temperature 270℃~300℃ ℃, the temperature of the seventh zone is 270℃~300℃, the temperature of the eighth zone is 270℃~300℃, the temperature of the ninth zone is 270℃~300℃, the temperature of the head is 290℃~310℃, the screw speed is 300r / min~600r / min, and the pressure is 6-14MPa;

[0027] 3): The material ...

Embodiment 2

[0029] 1): Take 30 parts of PPO resin and 51 parts of PA resin according to the weight ratio, and dry them in an oven; add 5 parts of compatibilizer, 12 parts of toughening agent, 1.7 parts of flow modifier, and 0.3 parts of antioxidant Stir and mix in a high-speed mixer for 3 to 5 minutes;

[0030] 2): The material obtained in step (1) is fed into the twin-screw extruder through the main feeder, and melted and extruded through the twin-screw extruder. The extrusion process is: twin-screw extruder temperature zone: one zone Temperature 190℃~250℃, zone 2 temperature 220℃~270℃, zone 3 temperature 270℃~300℃, zone 4 temperature 270℃~300℃, zone 5 temperature 270℃~300℃, zone 6 temperature 270℃~300℃ ℃, the temperature of the seventh zone is 270℃~300℃, the temperature of the eighth zone is 270℃~300℃, the temperature of the ninth zone is 270℃~300℃, the temperature of the head is 290℃~310℃, the screw speed is 300r / min~600r / min, and the pressure is 6-14MPa;

[0031] 3): The material ob...

Embodiment 3

[0033] 1): Take 35 parts of PPO resin and 44.3 parts of PA resin according to the weight ratio, and dry them in an oven; add 5 parts of compatibilizer, 13 parts of toughening agent, 2 parts of flow modifier, and 0.3 parts of antioxidant Stir and mix in a high-speed mixer for 3 to 5 minutes;

[0034] 2): The material obtained in step (1) is fed into the twin-screw extruder through the main feeder, and melted and extruded through the twin-screw extruder. The extrusion process is: twin-screw extruder temperature zone: one zone Temperature 190℃~250℃, zone 2 temperature 220℃~270℃, zone 3 temperature 270℃~300℃, zone 4 temperature 270℃~300℃, zone 5 temperature 270℃~300℃, zone 6 temperature 270℃~300℃ ℃, the temperature of the seventh zone is 270℃~300℃, the temperature of the eighth zone is 270℃~300℃, the temperature of the ninth zone is 270℃~300℃, the temperature of the head is 290℃~310℃, the screw speed is 300r / min~600r / min, and the pressure is 6-14MPa;

[0035] 3): The material ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com