Device for improving ribbon matrix production stability

A technology of stability and gas tank, applied in the direction of coating, etc., can solve the problems of unable to convey air pressure, cannot produce normally, damage the pressure regulating valve, etc., to achieve the effect of ensuring a safe and stable production state and improving production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

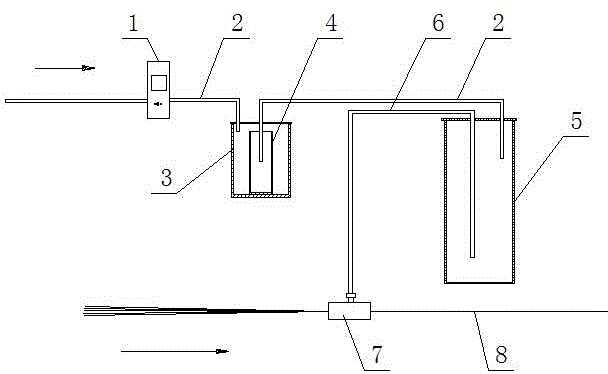

[0011] The device for improving the stability of parallel belt production consists of a compressed air precision pressure regulating valve 1, an air pipe 2, a double-set air tank large tank 3, a double-set air tank inner tank 4, a resin tank 5, a resin delivery pipe 6 and a parallel belt The mold 7 is formed, the air inlet of the compressed air precision pressure regulating valve 1 is connected to the air source through the air pipe 2, the air outlet of the compressed air precision pressure regulating valve 1 is connected to the double-set air tank large tank 3 through the air pipe 2, and the double-set air The inner tank 4 of the double-sleeved air tank is installed in the large tank 3, and the inner tank 4 of the double-sleeved air tank is connected to the resin tank 5 through the air pipe 2, and the resin tank 5 is connected by the resin delivery pipe 6 and has a mold, 7. The upper openings of the large tank 3 and the resin tank 5 of the double sleeve type gas tank are close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com