Soilless culture matrix flow production line, production technology and pallet

A technology of soilless culture substrate and production process, applied in the field of soilless culture, can solve the problems of unreasonable substrate shape design, danger of foaming agent, cumbersome production process, etc., so as to save the space and cost occupied by equipment, reduce Hazardous, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

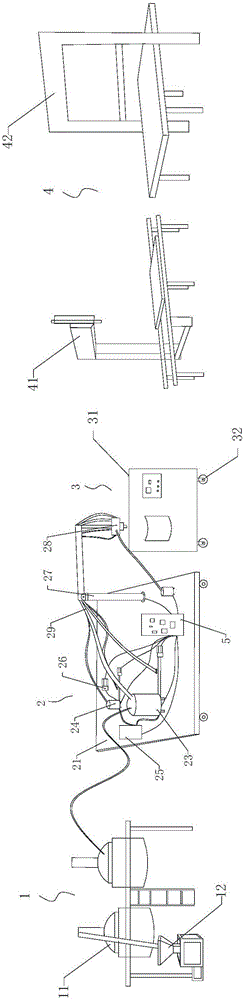

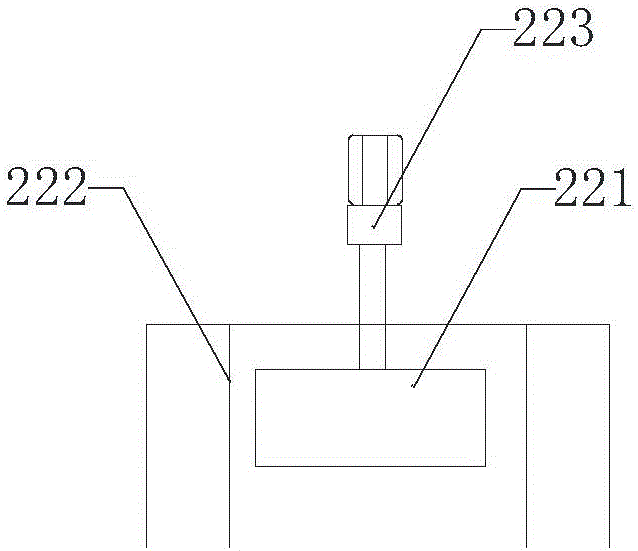

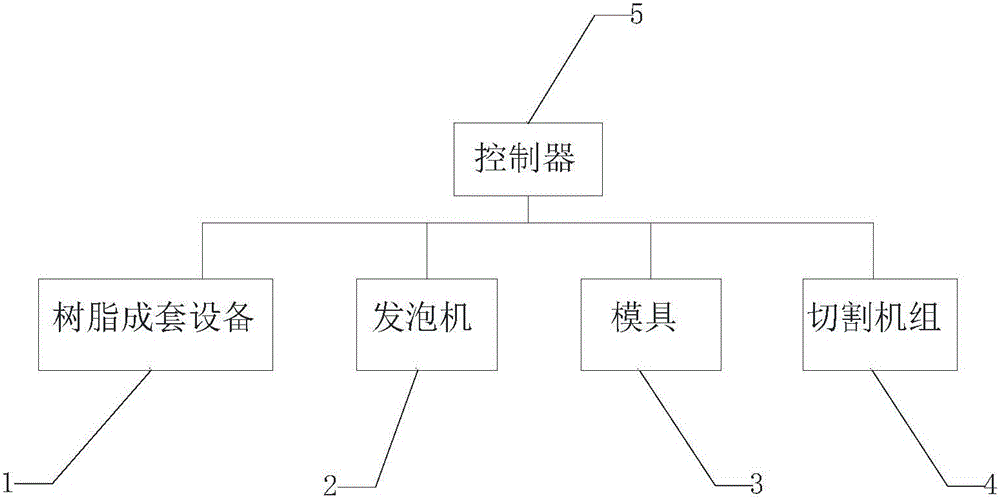

Method used

Image

Examples

Embodiment 1

[0110] A soilless culture medium, including 0.9 parts of DC-193 type silicone oil, 1.1 parts of cell opening agent and 1.3 parts of color paste.

Embodiment 2

[0112] A soilless culture medium, including 1.2 parts of DC-193 type silicone oil, 1.4 parts of cell opening agent and 1.6 parts of color paste.

Embodiment 3

[0114] A soilless culture medium, including 1 part of DC-193 silicone oil, 1.26 parts of cell opener and 1.47 parts of color paste.

[0115] The open porosity ratios of different additive ratios in the present invention are compared at different temperatures, as shown in Table 1.

[0116] Table 1 Opening ratio of different additive ratios at different temperatures

[0117] Auxiliary 5℃ 10℃ 20℃ 30℃ Example 1 60 94 96 55 Example 2 65 95 94 52 Example 3 62 97 98 56

[0118] It can be seen from the comparison in Table 1 that the opening rate of the substrate is the largest at a temperature of 10°C to 20°C by using the auxiliary agent of the present invention, and the opening rate of the substrate will decrease significantly if it exceeds this range; and using the auxiliary agent of the present invention, the substrate The opening rate can reach more than 95%, which can well meet the needs of soilless cultivation.

[0119] A tray made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com