Semiconductor silicon rod grinding device for high-end equipment manufacturing

A semiconductor and equipment technology, applied in the field of semiconductor silicon rod grinding devices for high-end equipment manufacturing, can solve the problems of affecting grinding quality, inconvenient mechanical clamping and feeding, unstable grinding rhythm, etc., to improve efficiency and stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

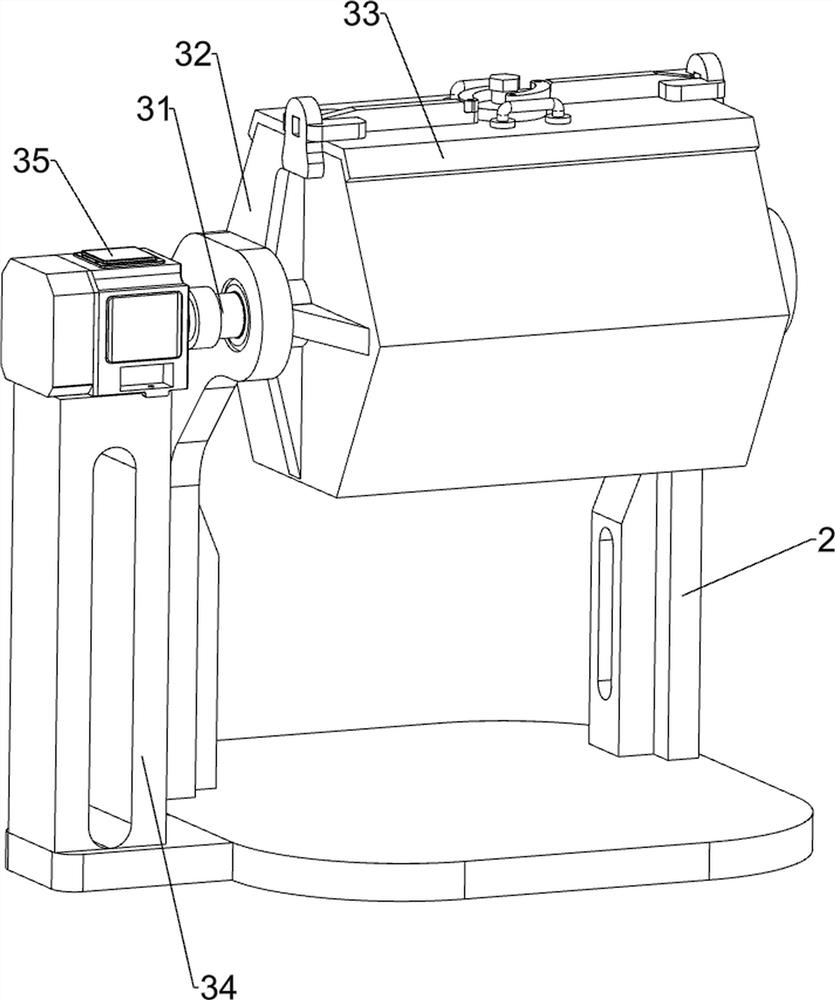

[0025] Such as figure 1 As shown, a semiconductor silicon rod grinding device for high-end equipment manufacturing includes a bottom plate 1, a support frame 2, a grinding mechanism 3, and a locking mechanism 4. A support frame 2 is symmetrically arranged on the top of the bottom plate 1. Between the two support frames 2 A grinding mechanism 3 is arranged between them, and a locking mechanism 4 is arranged on the top of the grinding mechanism 3 .

[0026] A semiconductor silicon rod grinding device for high-end equipment manufacturing, using the rotating operation of the grinding mechanism 3 to keep the abrasive in the drum always on the outer peripheral side of the inner wall of the drum due to centrifugal force, and generate a fluid layer under the relative action of the inner wall of the hexagonal cylinder , in the fluidized layer, the relative movement of the abrasive material and the silicon rod will continuously produce fine grinding on the surface of the silicon rod, so...

Embodiment 2

[0028] Such as figure 2 and image 3 As shown, on the basis of Embodiment 1, the grinding mechanism 3 includes a first rotating shaft 31, a hexagonal roller 32, a top cover 33, a fixed seat 34 and a servo motor 35, and the support frame 2 is provided with a first rotary shaft through a bearing. Rotating shaft 31, the middle part of the first rotating shaft 31 is provided with a hexagonal drum 32, the top of the hexagonal drum 32 is provided with a top cover 33, the front side of the bottom plate 1 is provided with a fixed seat 34, the top of the fixed seat 34 is provided with a servo motor 35, the output of the servo motor 35 The shaft is connected with the first rotating shaft 31 through a coupling.

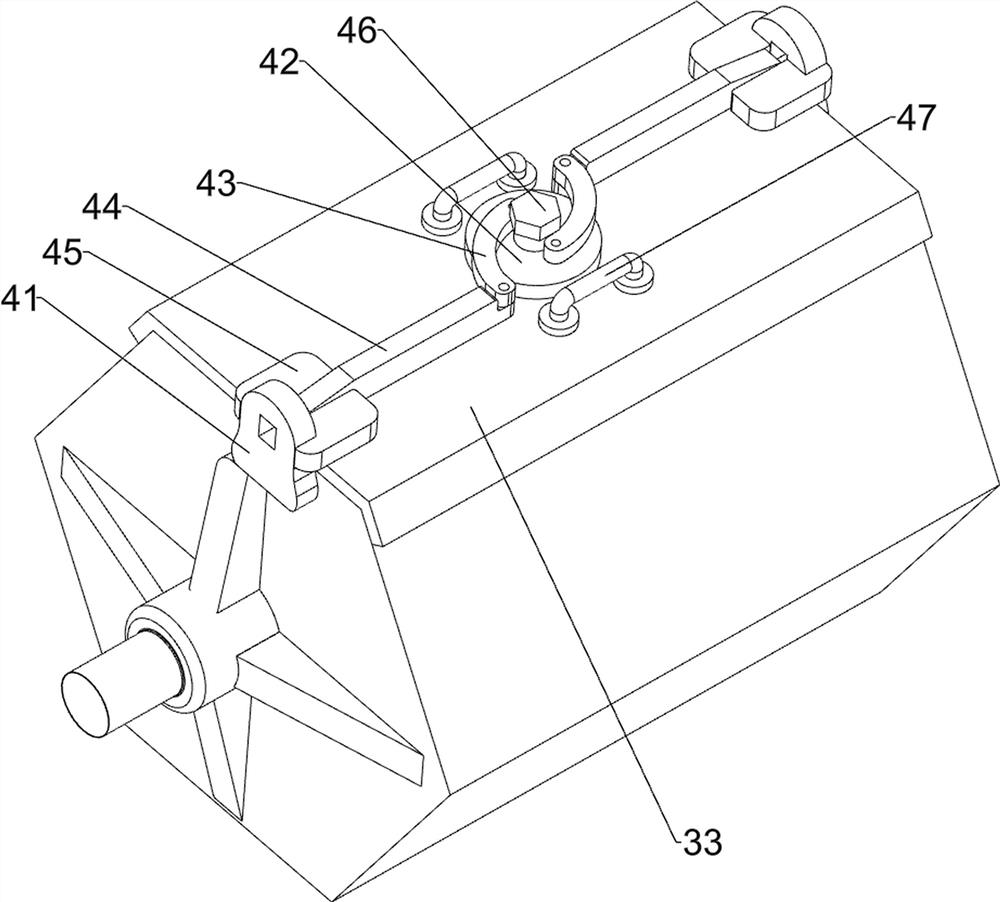

[0029] The locking mechanism 4 includes a lock block 41, a rotating disk 42, an arc bar 43, a wedge block 44, a guide block 45, a screw rod 46 and a handle 47, and the tops of the left and right sides of the hexagonal drum 32 are provided with lock blocks 41, and the top cover...

Embodiment 3

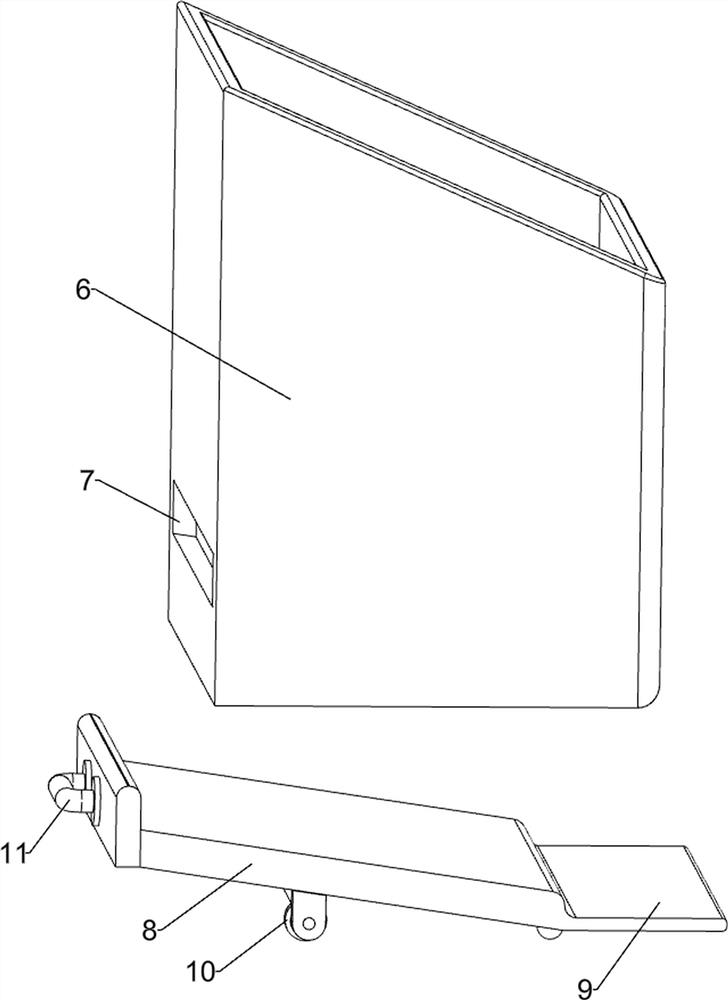

[0032] Such as Figure 4 and Figure 5 As shown, on the basis of Embodiment 2, it also includes a first fixed frame 5, a blanking box 6, a loading plate 8, a discharging plate 9, a roller assembly 10 and a push handle 11, and the upper part of the support frame 2 is provided with The first fixed frame 5, the top of the first fixed frame 5 is provided with a blanking box 6, the lower part of the left and right sides of the blanking box 6 is provided with a rectangular hole 7, and the sliding type in the rectangular hole 7 is provided with a loading plate 8, and the loading plate 8 A discharge plate 9 is arranged near the right side, a roller assembly 10 is arranged in the middle of the bottom of the loading plate 8 , and a push handle 11 is arranged on the left side of the loading plate 8 .

[0033] On the other hand, the staff can slide the silicon rods on the loading plate 8 in the discharge box 6 to the discharge plate 9 by pushing the push handle 11. Due to the capacity li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com