Ultra-large type straw methane tank

A biogas digester and super-large technology, applied in the field of biogas digesters, can solve the problems of insufficient nozzle spraying effect, insufficient gas production of biogas digesters, unfavorable saving of manpower and material resources, etc., achieve good heat preservation effect, improve safety, and save labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

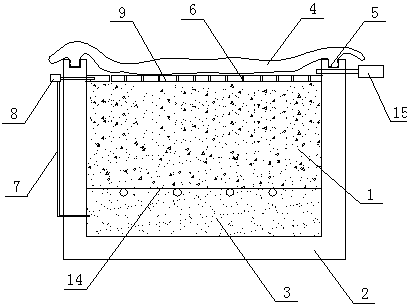

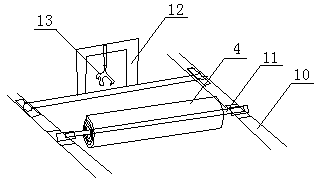

[0015] like figure 1 , figure 2 It shows that a large -scale straw biogas tank, including the fermentation pool 2 of the surrounding sink 5, includes the fermentation pool 2 separate from the water transmitting composition 14 at the bottom of the biogas area at the bottom of the fermentation pool 2 and the fermentation area in the middle and upper part. 1. The upper part of the fermentation area 1 is set with a small hole 6 drilling support board 9. Support plate 9 and the upper part of the fermentation pool 2 are set to a gas hood 4. The surroundings of the gas hood 4 are connected to the meter 2 watershed sink 5, which is below the gas hood 4 outside the fermentation pond 2 outside the fermentation pond 2 2 The negative pressure gas collection and storage device 15 is connected. The biogas in the biogas area is raised to the drum irrigation support plate through the circulating pump. The biogas liquid on the double layer of the pores of the drum irrigation support plate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com