Test strip in matrix distribution, production process of test strip and detection method

A detection method and production process technology, which is applied in the direction of chemiluminescence/bioluminescence, and analysis by making materials undergo chemical reactions, can solve problems such as high cost and inconvenience, and achieve convenient use, easy immersion, and simplified detection mechanism Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

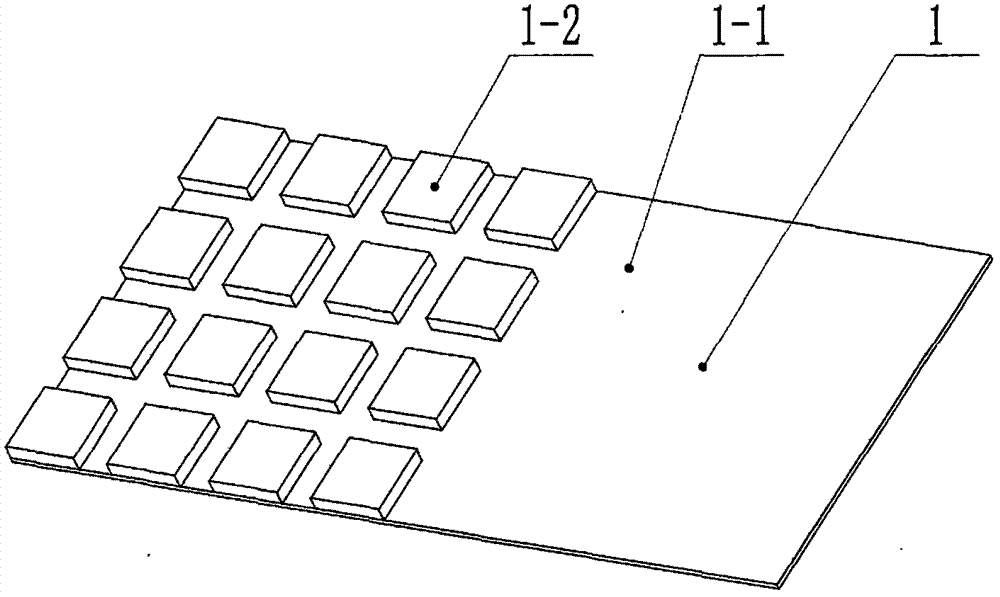

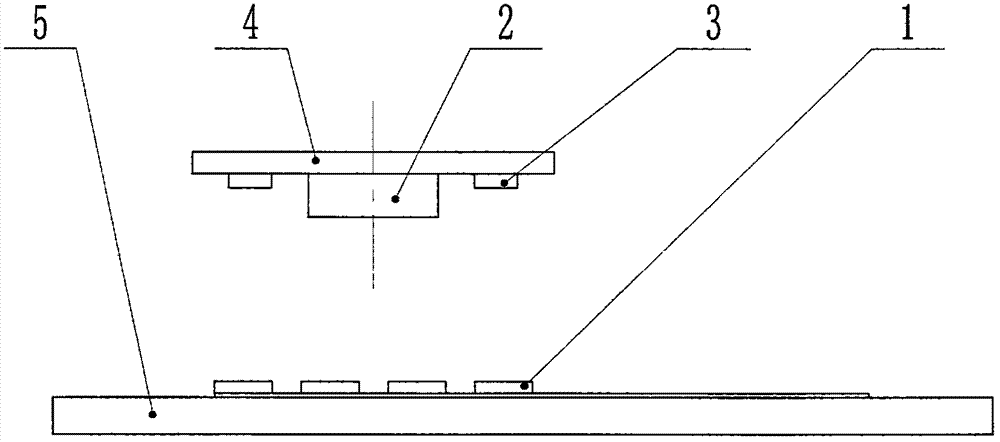

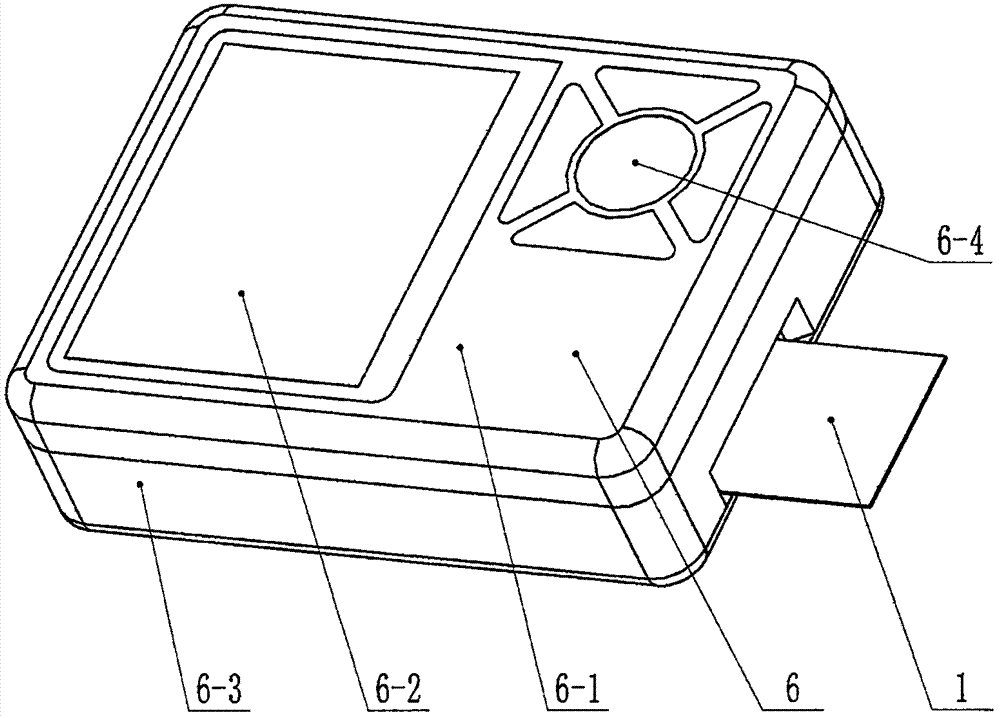

[0010] A kind of matrix distribution test strip of the present invention and the production technology of test strip and detection method embodiment example figure 1 As shown, the shape of the substrate 1-1 of the test strip 1 is rectangular, and the aspect ratio is less than or equal to 4 times. The number is greater than or equal to 2, the number of vertically arranged columns is greater than or equal to 2, the number of medicine blocks 1-2 arranged in each row or column is greater than or equal to 2, and the shape of medicine blocks 1-2 is a regular polygon or a rectangle Or it is circular, the length of the side or the radius is 1-10mm, and the distance between the rows and columns of the pills 1-2 is between 1-5mm; with the shape of the test strip 1 There are two alternative methods for the production process of the test strip 1, which are two-time pasting, three-time cutting method and point-by-point glue injection pasting method; According to the number of drug blocks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com