Purely natural organic nutritional matrix and preparation method thereof

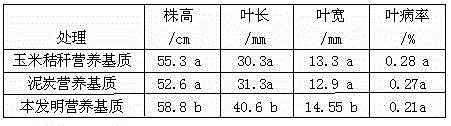

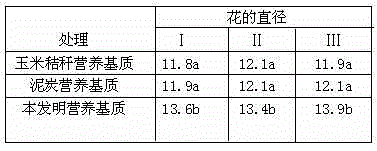

An organic nutrition, pure natural technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as being unsuitable for green pollution-free products, peat nutrient matrix nutritional deficiencies, and easy to grow peony. The effect of rowing, increasing the number of flowering, and increasing the ornamental

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

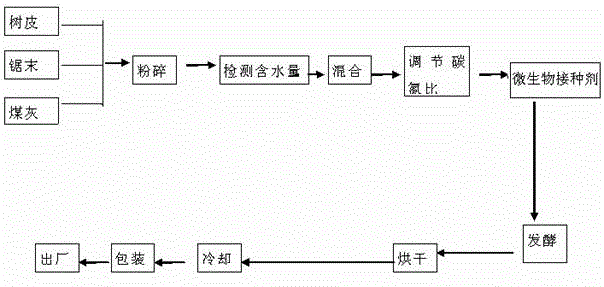

Method used

Image

Examples

Embodiment 1

[0015] Formula: bark 60kg, sawdust 30kg, coal ash 10kg, biological fertilizer starter 0.5kg, cow dung 1kg.

[0016] Specific manufacturing method: crush the above raw materials through a pulverizer, mix bark, sawdust, and coal ash, control the carbon-to-nitrogen ratio at 20, and control the pH value at 8.0, and then inoculate the biological fertilizer starter on the cow dung to form a microbial inoculant , added to the above mixed raw materials for stacking and fermentation. Generally, within 24 hours, the temperature rises to 50°C from the beginning, and within 48 hours, the temperature can rise to 60°C. When the temperature reaches 70°C, the pile needs to be turned. Such a temperature can kill all pathogenic bacteria and cordyceps seeds during fermentation; ferment for 7 days in spring, summer and autumn, and 10 days in winter to complete the fermentation, and then transport it to the dryer and cooler for drying and cooling Finally, it is packaged, which is the finished prod...

Embodiment 2

[0018] Formula: bark 40kg, sawdust 20kg, coal ash 30kg, biological fertilizer starter 1 kg, chicken manure 5 kg.

[0019] Specific manufacturing method: the above-mentioned obtained raw materials are pulverized by a pulverizer first, and the biological fertilizer starter is first inoculated on the chicken manure to form a microbial inoculant, and the microbial inoculant is fully mixed with bark, sawdust, and coal ash, and made The water content is controlled at about 50%, the carbon-nitrogen ratio is controlled at 35, and the pH value is controlled at 7.0, and then stacked and fermented. Generally, within 22 hours, the temperature rises to 51°C from the beginning, and within 50 hours, the temperature can rise to 61°C. °C, when the temperature reaches 72 °C, turn over is required. Such a temperature can kill all pathogenic bacteria and cordyceps seeds during fermentation; ferment for 8 days in spring, summer and autumn, and 10 days in winter to complete the fermentation, and th...

Embodiment 3

[0021] Formula: bark 50kg, sawdust 40kg, coal ash 20kg, biological fertilizer starter 0.1kg, cow dung 1kg.

[0022] Specific manufacturing method: pulverize the raw materials obtained above through a pulverizer, first inoculate the biological fertilizer starter onto cow dung to form a microbial inoculant, fully mix the microbial inoculant with bark, sawdust, and coal ash, and make The water content is controlled at about 47%, the carbon-nitrogen ratio is controlled at 27, and the pH value is controlled at 7.5, and then stacked and fermented. Generally, within 22 hours, the temperature rises to 49°C from the beginning, and within 49 hours, the temperature can rise to 59°C. °C, when the temperature reaches 75 °C, turn over is required. Such a temperature can kill all pathogenic bacteria and cordyceps seeds during fermentation; ferment for 9 days in spring, summer and autumn, and 9 days in winter to complete the fermentation, and then transport it to the dryer and cooler for dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com