Oil well filling packer particle precipitation and oil increasing method for crack-type oil and gas reservoirs

A technology for oil and gas wells and oil and gas reservoirs, which is applied in the field of oil and gas well exploitation, and can solve problems such as the failure to effectively solve the problem of water discharge, the failure of plugging medium degradation, and the life span of more than 3 months, so as to improve the plugging effect and reduce the diversion Ability, the effect of increasing the degree of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

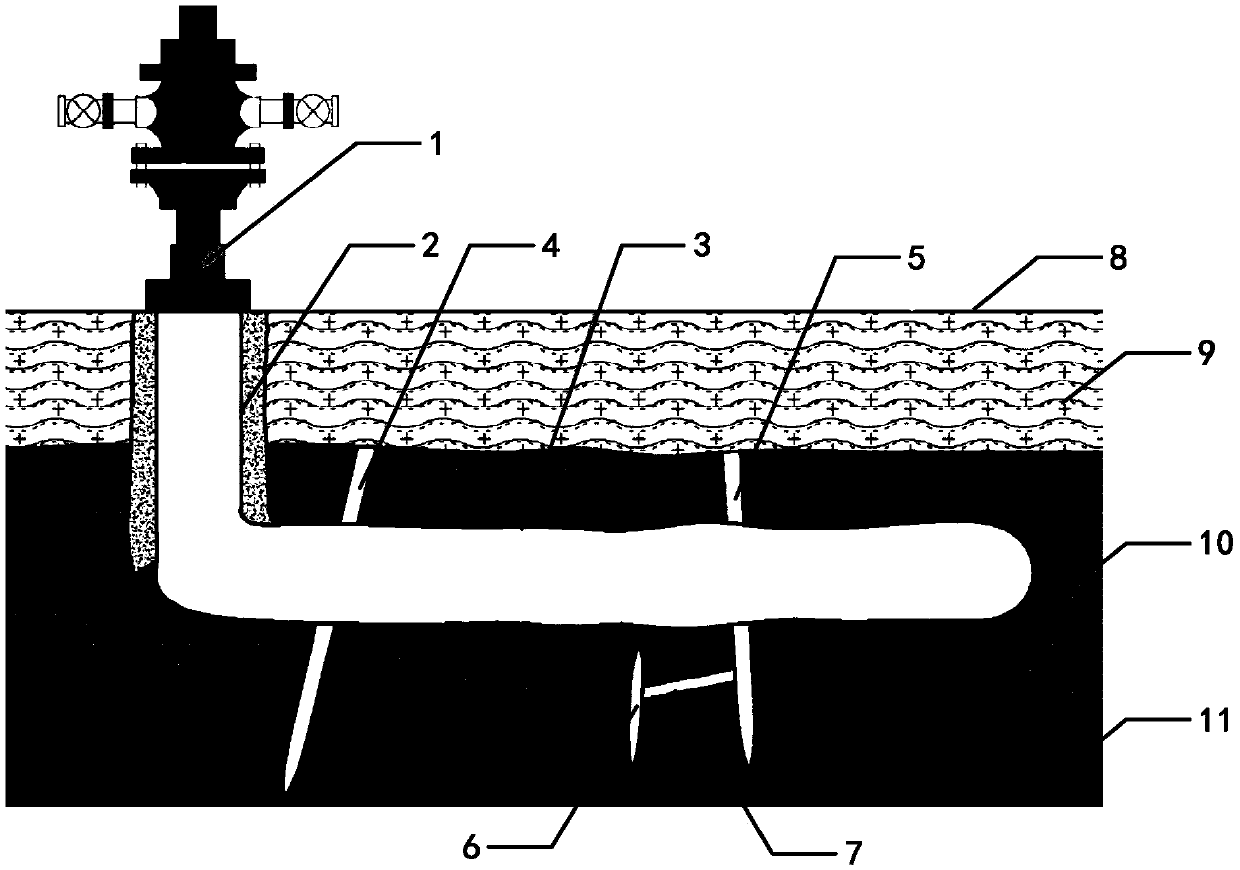

Embodiment 1

[0062] This example provides a method for filling the oil and gas wells of fractured oil and gas reservoirs with packing particles to reduce water and increase oil production. The method directly fills the wellbore and fractures with packing particles to realize the plugging of the fractures, specifically including the following steps: ( a1) Filling fluid carrying packer particles is injected into the wellbore and fractures through the wellhead; until the formation fracture / fracture extension pressure is reached or exceeded, or until the injection volume under the unit injection pressure is close to zero, or until the preset isolation is reached (a2.1) Run the flushing pipe to clean up the packer particles in the wellbore; (a2.2) Put into production.

[0063] In the above step (a1), there are three criteria for the filling termination of the injected filling fluid, corresponding to the wellbore of the production section with different structures and different fractures. In prac...

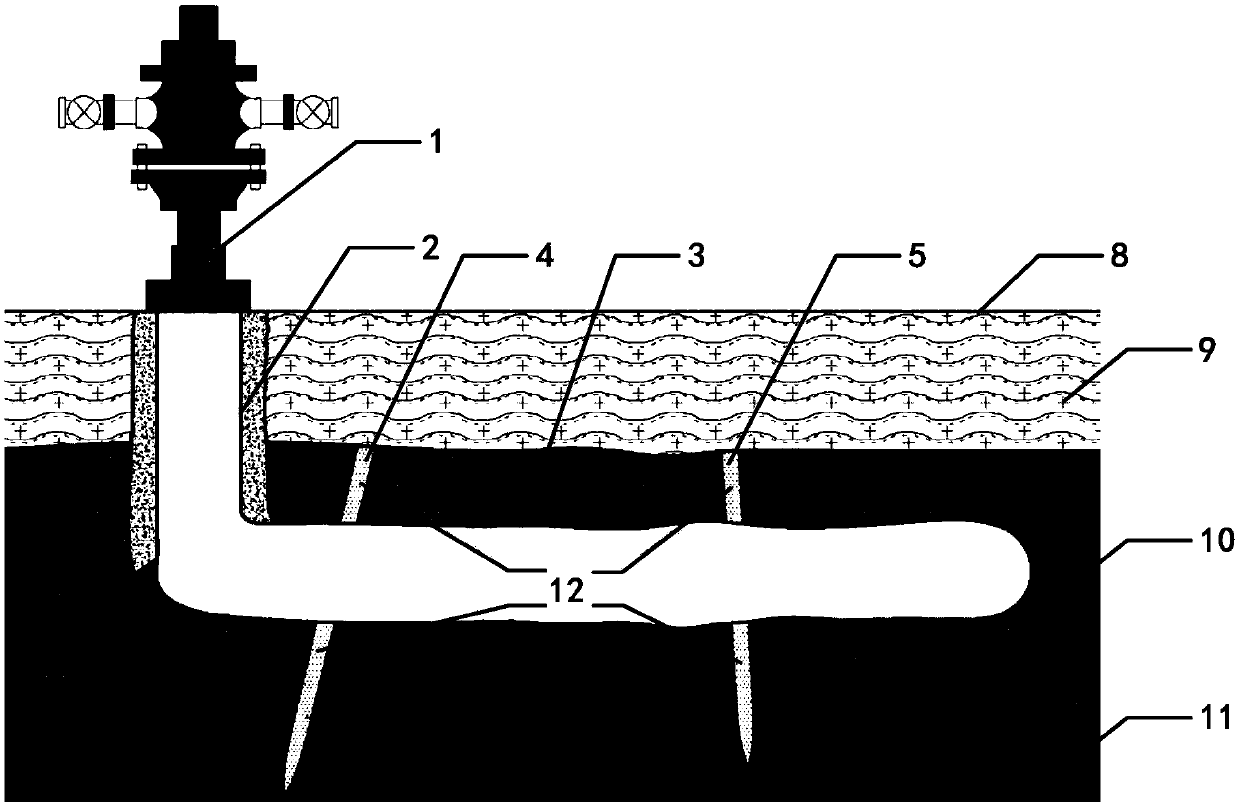

Embodiment 2

[0070] Embodiment 2 is a further optimization of Embodiment 1. According to the technical solution described in Example 1, when the oil and gas well is put into production, since the fluid in the fracture flows from the fracture to the wellbore, the fluid will drive some particles to be recovered to the wellbore and produced, which brings the following problems: First, some fractures After the packer particles in the fracture are recovered, the filling degree of the fracture packer decreases, and the ability to control water and hinder water flow decreases; especially for some wide erosive fractures, a large number of packer particles entering the fracture will be recovered after being put into production. to the wellbore, so that the plugging and water control effects of fractures cannot be maintained; the second is that the output of the packer particles will have a certain impact on the operation of the downhole electric pump, such as the risk of pump stuck; the third is tha...

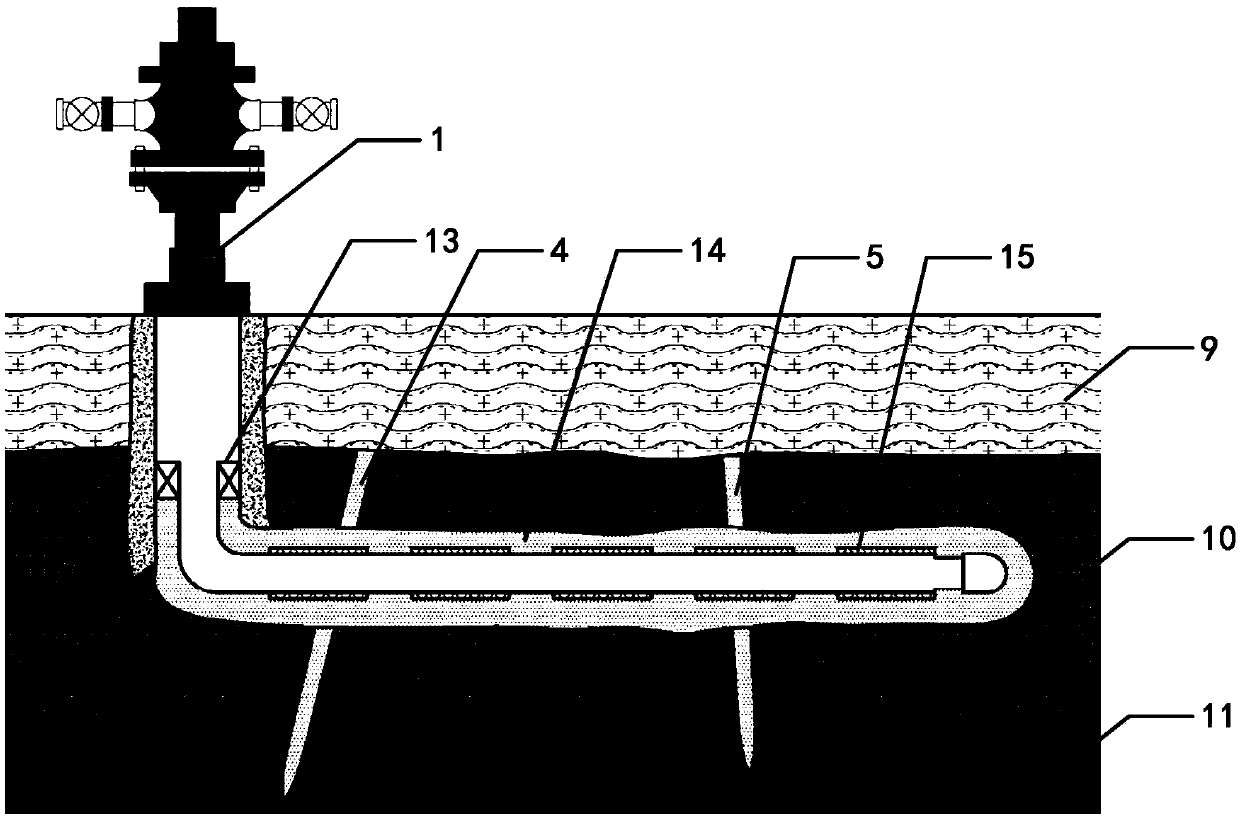

Embodiment 3

[0079] Embodiment 3 is a further optimization of Embodiment 2. The technical solution described in Example 2 has the following problems: First, after the fracture is filled with packer particles, although the conductivity is greatly reduced compared with that before filling, its permeability is still higher than that of the matrix relative to the matrix (several times to hundreds of times), there is still a certain amount of water produced, and it is necessary to further reduce the water production of fractures; second, there are many reasons for water production along the production section of the wellbore, some of which are caused by local high-permeability matrix water production, and water is only controlled in fractures The effect is not necessarily ideal.

[0080] In this regard, Example 3 uses a water control screen to further improve the water control capability. Such as Figure 4 As shown, the difference between this embodiment and embodiment 2 is that the screen us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com