Production line automation transit warehouse

A production line and warehouse technology, which is applied in the field of automatic transfer warehouses of sheet metal production lines, can solve the problems of low production efficiency and low utilization of warehouse space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

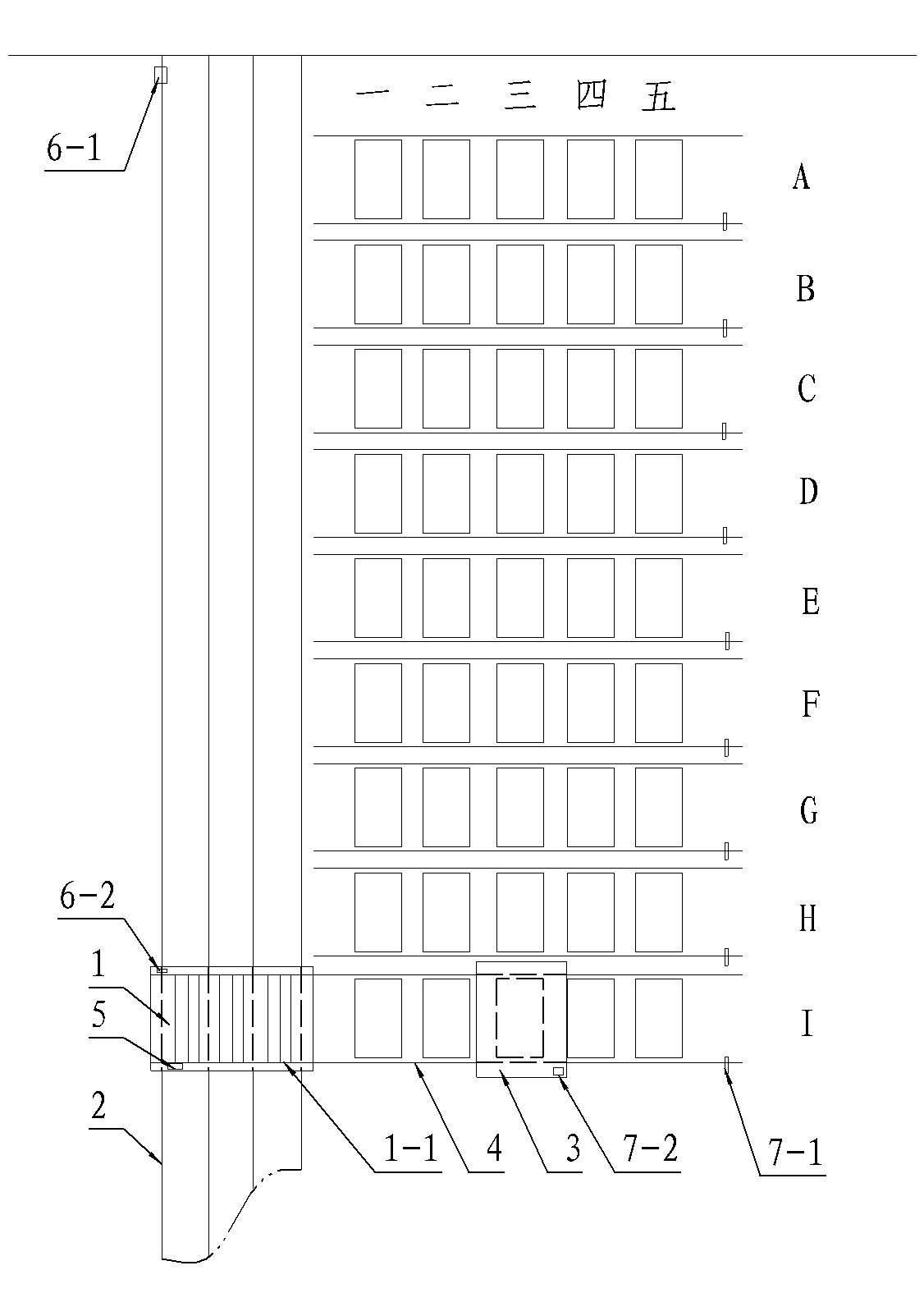

[0011] figure 1 The automatic transfer warehouse of the production line includes a transport vehicle 1 walking on the production line channel. The transport vehicle 1 is equipped with a stacker track 1-1 on the vehicle and a stacker position sensor 5 on the vehicle. The track 2 of the transport vehicle 1 One side of A-I is provided with a total of 9 rows of positions, each row of positions is provided with a warehouse stacker track 4 for docking with the stacker track 1-1 formed by two steel rails, and each row has one to five A total of 5 positions, in the first row of the warehouse, there is a stacker 3 on the stacker track 4 of the third position, and a transporter position for detecting the position of the transporter 1 on the track 2 is provided on the production line channel Sensor, this transport vehicle position sensor is made of the transport v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com