Wood-bamboo straw fiberboard and composite board and post wet-method production technique

A technology of straw fiber and fiberboard, applied in the field of wood bamboo straw fiberboard, composite board, and biofiber board manufacturing, can solve the problems of uneven surface and perimeter hard stratification, large water consumption, unused industrial production, etc. The effect of improving decorative performance, saving auxiliary materials and energy, and reducing the amount of wood used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

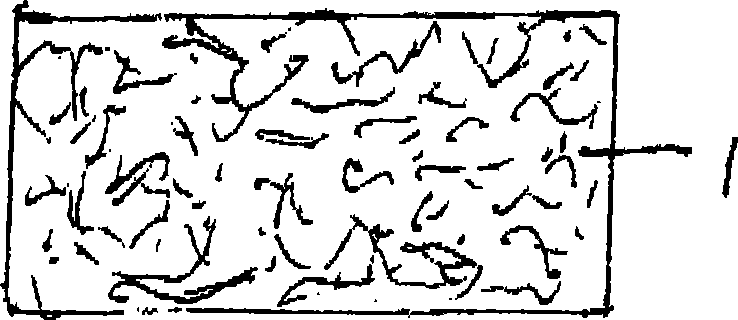

[0021] Such as figure 1 As shown, it is composed of wood, bamboo, straw or two materials with a density (380 ~ 1200KG / M 3 ) Different fiberboards 1, add 3 to 5% tobacco rods and other natural insect repellents and preservatives.

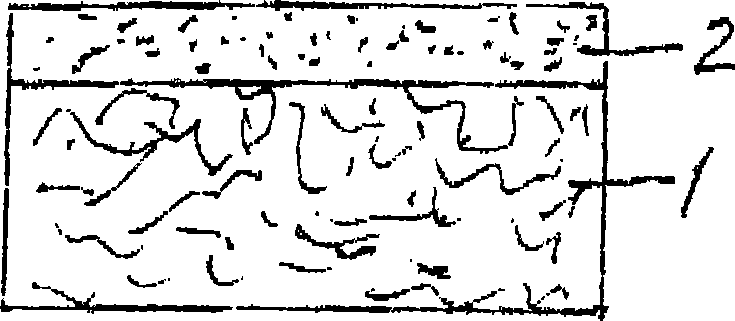

[0022] Such as figure 2 As shown: it is composed of one or more kinds of fibers 1 of wood, bamboo and straw, and a surface decorative composite fabric 2.

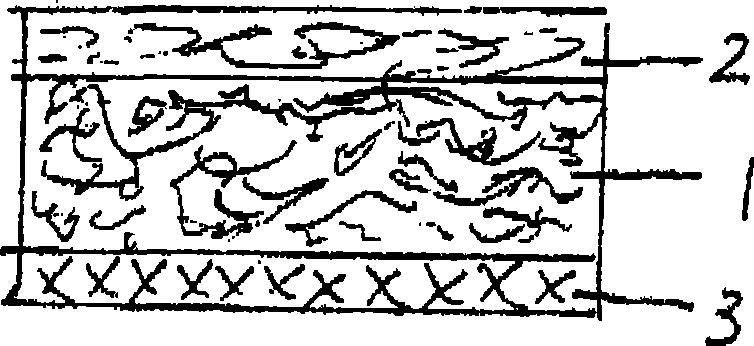

[0023] Such as image 3 As shown, it is composed of one or two kinds of fibers 1 of wood and straw, and 3-5% of tobacco rods, fiber powder and other natural insect-proof and preservatives can also be added, and the surface decoration fabric 2 strengthens the balance cloth layer 3. The surface can be It can be a plane or a color embossed pattern.

[0024] The specific manufacturing method is as follows: according to the dry method of fiber production, wood, bamboo, cotton, dried pepper, etc. are chipped, steamed and softened, and the fibers are obtained by heat grinding, and dried by an air cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com