Method for preparing high-softening-point rosin glyceride

A technology of rosin glyceride and high softening point, which is applied in the chemical modification of natural resins, etc., to achieve low acid value, good quality, and low acid value of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

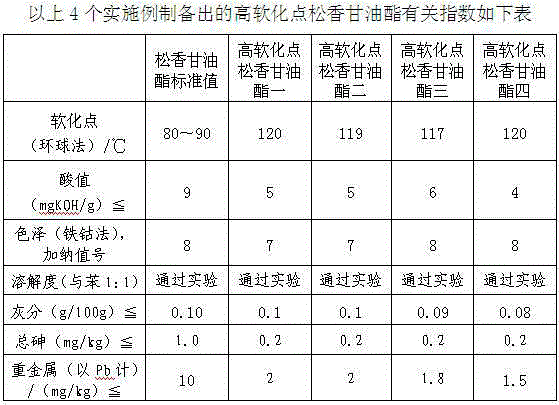

Examples

Embodiment 1

[0020] The preparation method of this high softening point rosin glyceride comprises the following steps:

[0021] A, the rosin of 100 weight parts, the maleic acid of 20 weight parts and the graphite of 0.2 weight part are put into reactor and mix;

[0022] B. Introduce N into the reaction kettle for protection reaction 2 , and reacted at 200°C for 120 minutes to obtain a modified rosin with a high softening point;

[0023] C, add the ZSM-5 molecular sieve catalyst of the load iron element of 3 weight parts and the glycerin of 24 weight parts again in reactor;

[0024] D, raising the reaction temperature to 240°C, and reacting at constant temperature for 7 hours;

[0025] E. stop N 2 Protection, after vacuum distillation for 20min, turn on N 2 protection, lower the temperature to below 220°C, and discharge the product to obtain rosin glyceride with high softening point.

Embodiment 2

[0027] The preparation method of this high softening point rosin glyceride comprises the following steps:

[0028] A, the rosin of 100 weight parts, the maleic acid of 20 weight parts and the graphite of 0.2 weight part are put into reactor and mix;

[0029] B. Introduce N into the reaction kettle for protection reaction 2 , react at 230°C for 45 minutes to obtain high softening point rosin;

[0030] C, add the ZSM-5 molecular sieve catalyst of the load iron element of 3 weight parts and the glycerin of 24 weight parts again in reactor;

[0031] D, raising the reaction temperature to 230°C, and reacting at constant temperature for 9 hours;

[0032] E. stop N 2 protection, after vacuum distillation for 30 minutes, turn on N 2 protection, lower the temperature to below 220°C, and discharge the product to obtain rosin glyceride with high softening point.

Embodiment 3

[0034] The preparation method of this high softening point rosin glyceride comprises the following steps:

[0035] A, the rosin of 100 parts by weight, the maleic acid of 30 parts by weight and the graphite of 0.2 parts by weight are put into reactor and mix homogeneously;

[0036] B. Introduce N into the reaction kettle for protection reaction 2 , react at 200°C for 120 minutes to obtain high softening point rosin;

[0037] C, add the ZSM-5 molecular sieve catalyst of the loaded iron element of 3 weight parts and the glycerol of 39 weight parts again in reactor;

[0038] D, raising the reaction temperature to 240°C, and reacting at constant temperature for 7 hours;

[0039] E. stop N 2 Protection, after vacuum distillation for 20min, turn on N 2 protection, lower the temperature to below 220°C, and discharge the product to obtain rosin glyceride with high softening point.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com